A kind of preparation method and application of emulsion polymerized salicylic acid molecularly imprinted membrane

A molecularly imprinted membrane and emulsion polymerization technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to single, cannot achieve single substance separation, efficient selective separation, etc., and achieve imprinting efficiency. High, fast adsorption kinetics, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

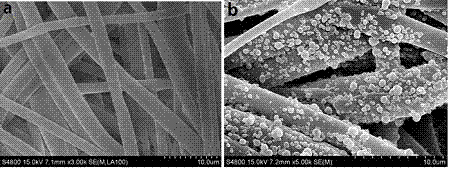

Image

Examples

Embodiment 1

[0033] (1) Mix 2 mmol of methacrylic acid (MAA), 5 mmol of ethylene glycol di(methacrylate) (EGDMA), and 0.2 g of Span 80 into 60 mL of toluene. (The concentration of MAA is 33.3 mmol L -1 , the concentration of EGDMA is 83.3 mmol L -1 , the concentration of Span 80 is 3.33 g L -1 ).

[0034] (2) Add 0.018 g salicylic acid (SA) into 10 mL deionized water (the concentration of SA is 1.8 g L -1 ), then add this solution to the above (1) and mix it with ultrasound for 15 minutes to form a water-in-oil emulsion, then add 0.0140 g of azoisobutyronitrile (AIBN) into the water-in-oil emulsion, keep it at room temperature for 30 minutes after ultrasonication for 5 minutes The upper organic layer was then removed to concentrate the emulsion.

[0035] (3) Take 100 mg PP film in a beaker containing 10 mL of acetone for 15 min, take it out to dry at room temperature, place it in a watch glass, add an appropriate amount of oleic acid to the watch glass to infiltrate the film surface, a...

Embodiment 2

[0045] (1) Mix 4 mmol 4-vinylpyridine (4-VP), 10 mmol ethylene glycol di(methacrylate) (EGDMA), and 0.6 g Span 80 into 60 mL toluene. (The concentration of 4-VP is 66.7 mmol L -1 , the concentration of EGDMA is 166.7 mmol L -1 , the concentration of Span 80 is 10.0 g L -1 ).

[0046] (2) Add 0.054 g salicylic acid (SA) into 30 mL deionized water (the concentration of SA is 1.8 g L -1 ), then add this solution to the above (1) and mix with ultrasound for 15 minutes to form a water-in-oil emulsion, then add 0.043 g of azoisobutyronitrile (AIBN) into the water-in-oil emulsion, keep it at room temperature for 30 minutes after ultrasonication for 5 minutes The upper organic layer was then removed to concentrate the emulsion.

[0047] (3) Take 120 mg PP film in a beaker containing 12 mL of acetone for 15 min, take it out to dry at room temperature, place it in a watch glass, add an appropriate amount of oleic acid to the watch glass to infiltrate the film surface, and then immer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com