Glue-spreading device

A gluing device and gluing technology, applied in the field of gluing, can solve the problems of affecting the quality of rubber materials, many processing steps, and high production costs, and achieve the effects of expanding the time range, reducing processing steps, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

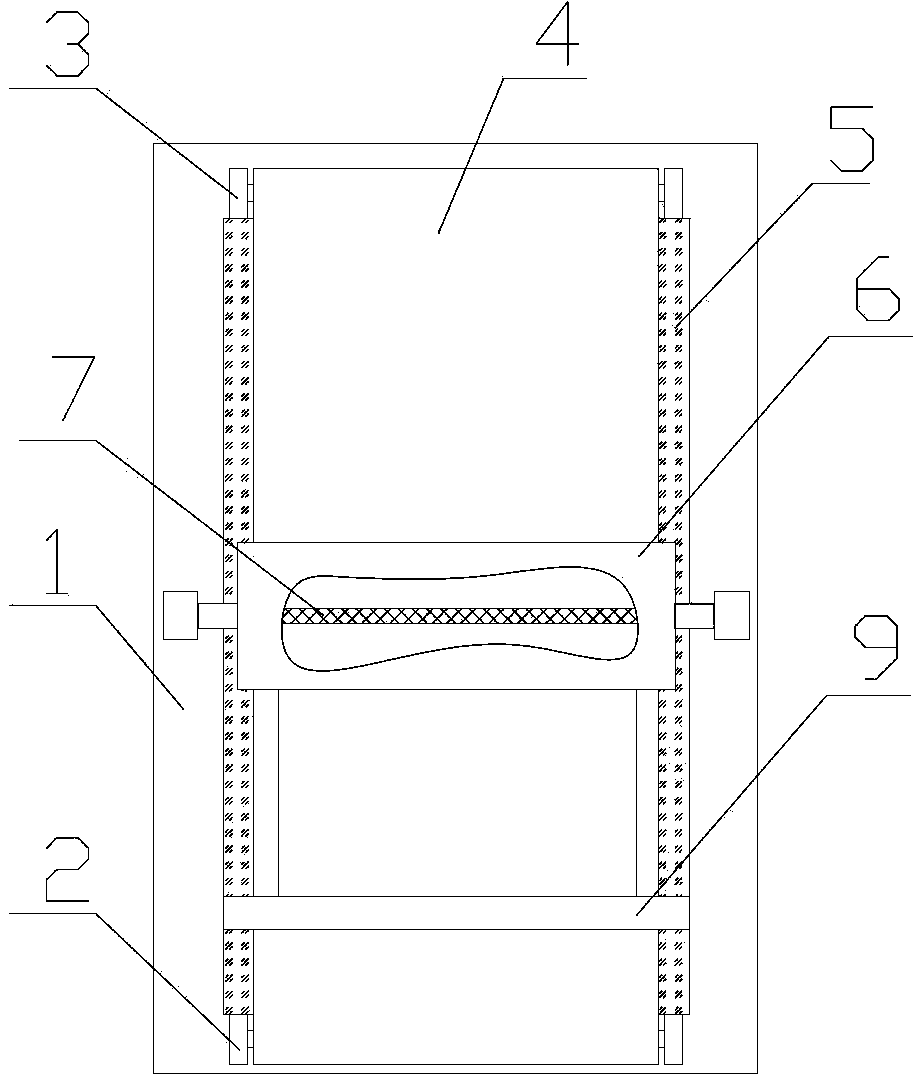

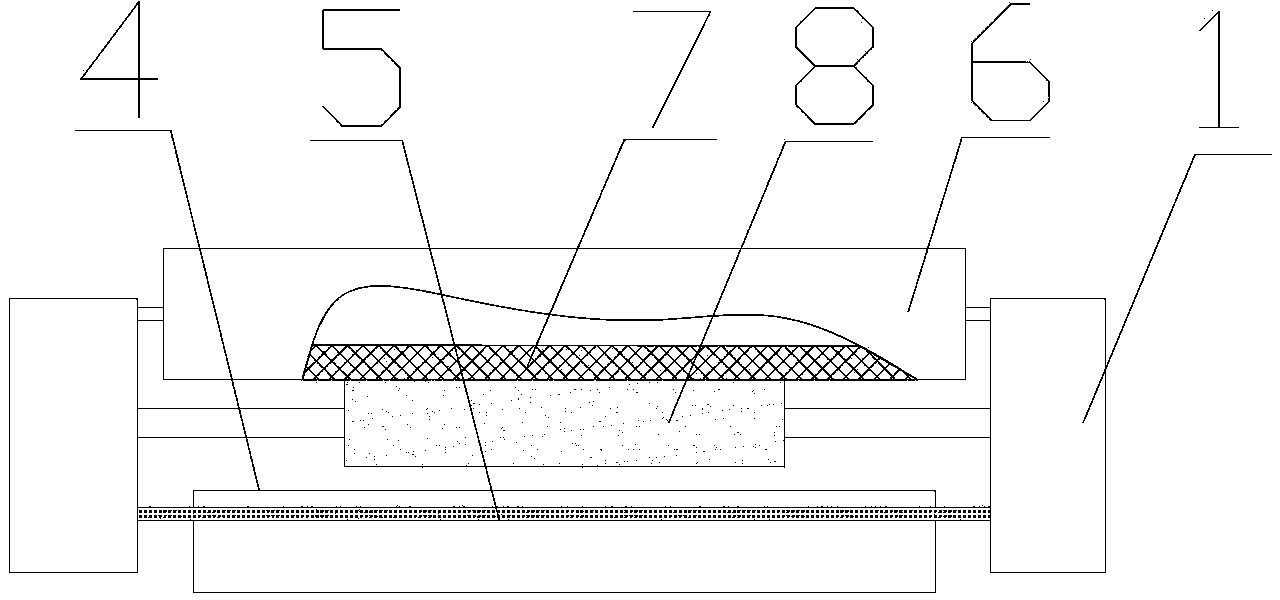

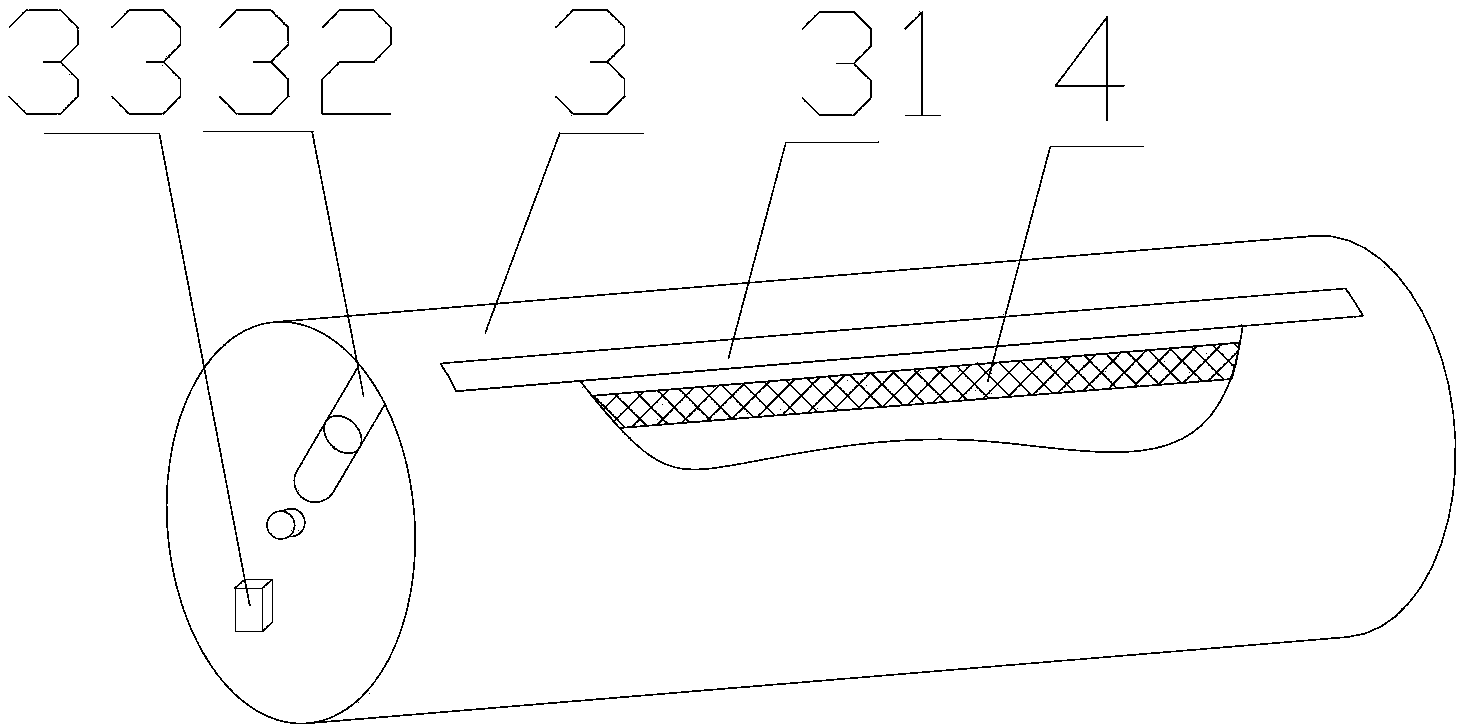

[0018] Such as figure 1 , figure 2 with image 3 as shown, figure 1 It is the top view of a kind of gluing device that the present invention proposes, figure 2 for figure 1 The right view of a gluing device in image 3 for figure 1 with figure 2 Schematic diagram of the structure of the middle-loaded rubber cartridge.

[0019] refer to Figure 1 to Figure 3 , a kind of gluing device that the present invention proposes, comprises: frame 1, conveyer belt mechanism, rubber cylinder 3, glue-out roller 4, glue-coating roller 5; Wherein:

[0020] The conveyor belt mechanism is installed on the frame 1, and the conveyor belt mechanism includes the conveyor belt 2; the rubber cylinder 3 is installed on the frame 1 and is located above the conveyor belt 2, and the rubber cylinder 3 is provided with a rubber inlet and outlet 31, and the rubber cylinder 3 can be opposite When the frame 1 rotates at a predetermined angle, the rubber roller 4 is installed in the rubber cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com