Nitrogen-protected brazing method of aluminum water tank sandglass pipe

A technology of nitrogen protection and brazing method, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of big three-package compensation risk, difficulty of Nocolock brazing flux, and decreased reliability, so as to prevent adverse effects and pass the standard The effect of high efficiency and full weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with specific embodiments in conjunction with the accompanying drawings.

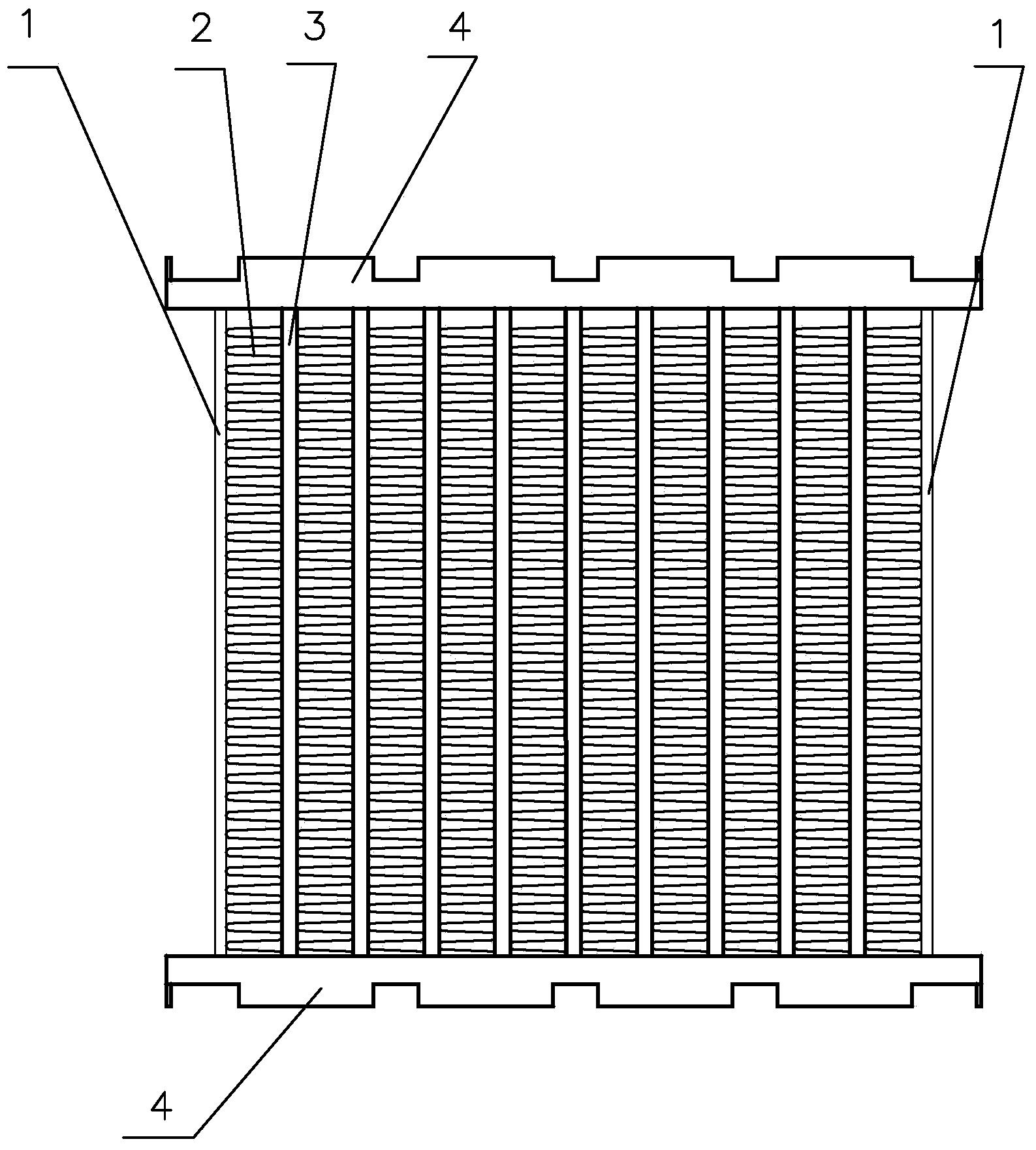

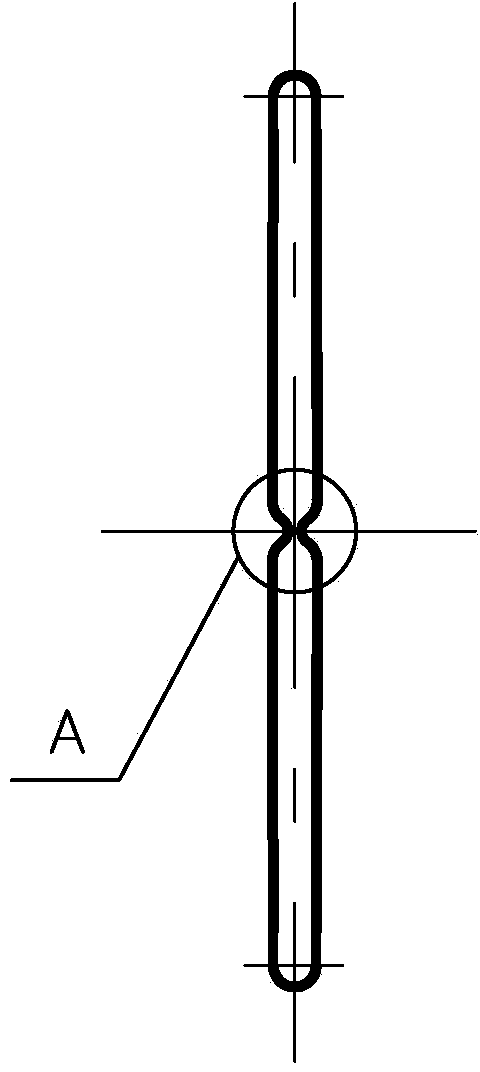

[0023] Referring to the accompanying drawings, a brazing method of an aluminum water tank hourglass tube under nitrogen protection according to the present invention, the hourglass tube 3 includes an outer Al-Si solder composite layer 5, an intermediate core material (also called a base material) 6, and an inner Al-Si solder composite layer 7, carry out according to the following steps:

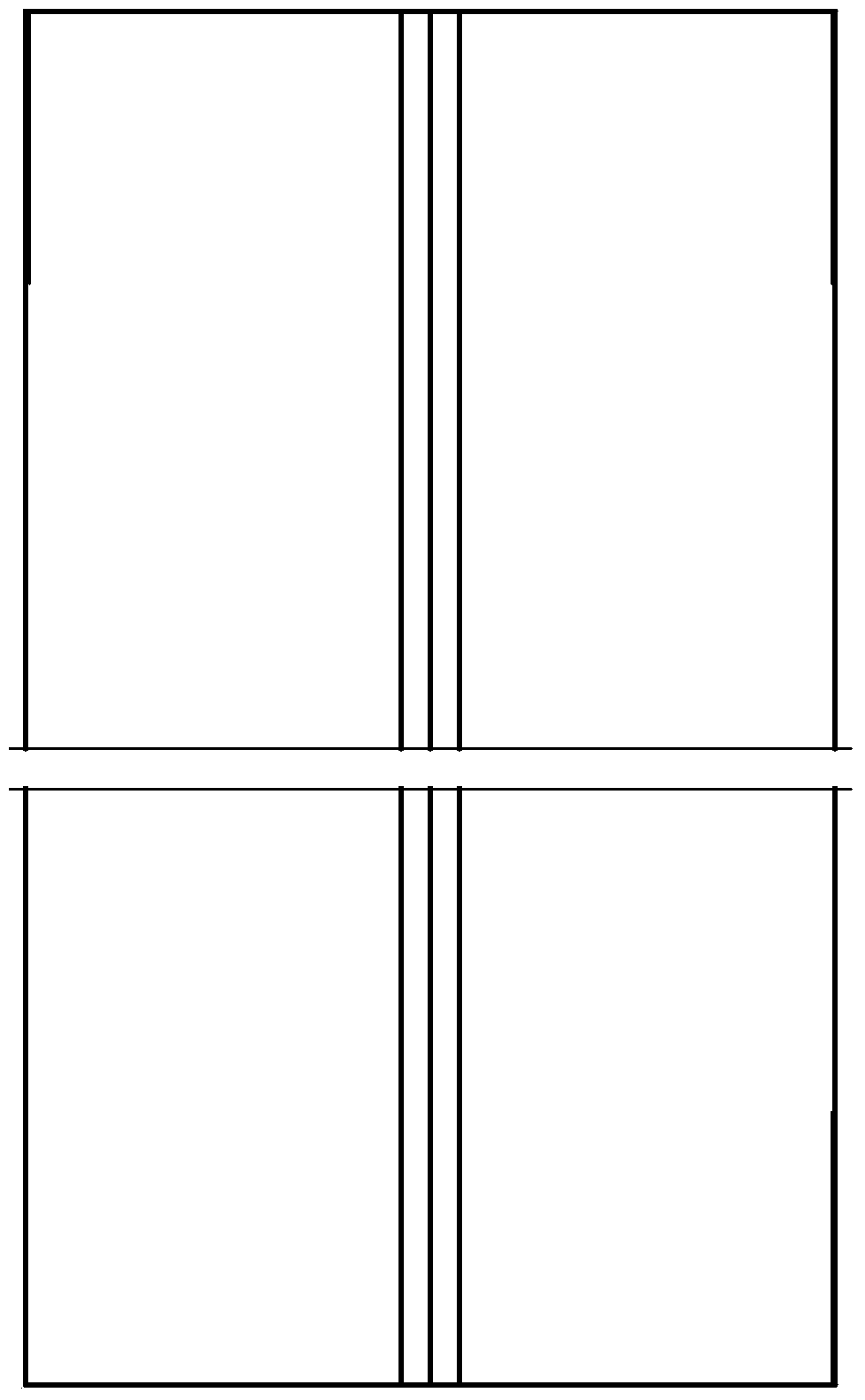

[0024] 1), two main boards 4, two side boards 1, and multiple hourglass tubes 3 and heat dissipation belts 2 stacked alternately form the core of the water tank;

[0025] 2) Use iron wire, packing tape or special brazing fixture to clamp the water tank core through the two side plates 1;

[0026] 3) After thermal degreasing or cleaning agent degreasing of the water tank core with a 150-250°C degreasing furnace, spray Nocolock flux on the heat dissipation bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com