Plate-fin type efficient heat exchanger core of aircraft air conditioning system

A technology for air conditioning systems and heat exchangers, which is used in heat exchange equipment, aircraft parts, indirect heat exchangers, etc. It can solve problems such as insufficient heat exchange effect, achieve optimal structural stability, optimized structural design, and uniform airflow distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

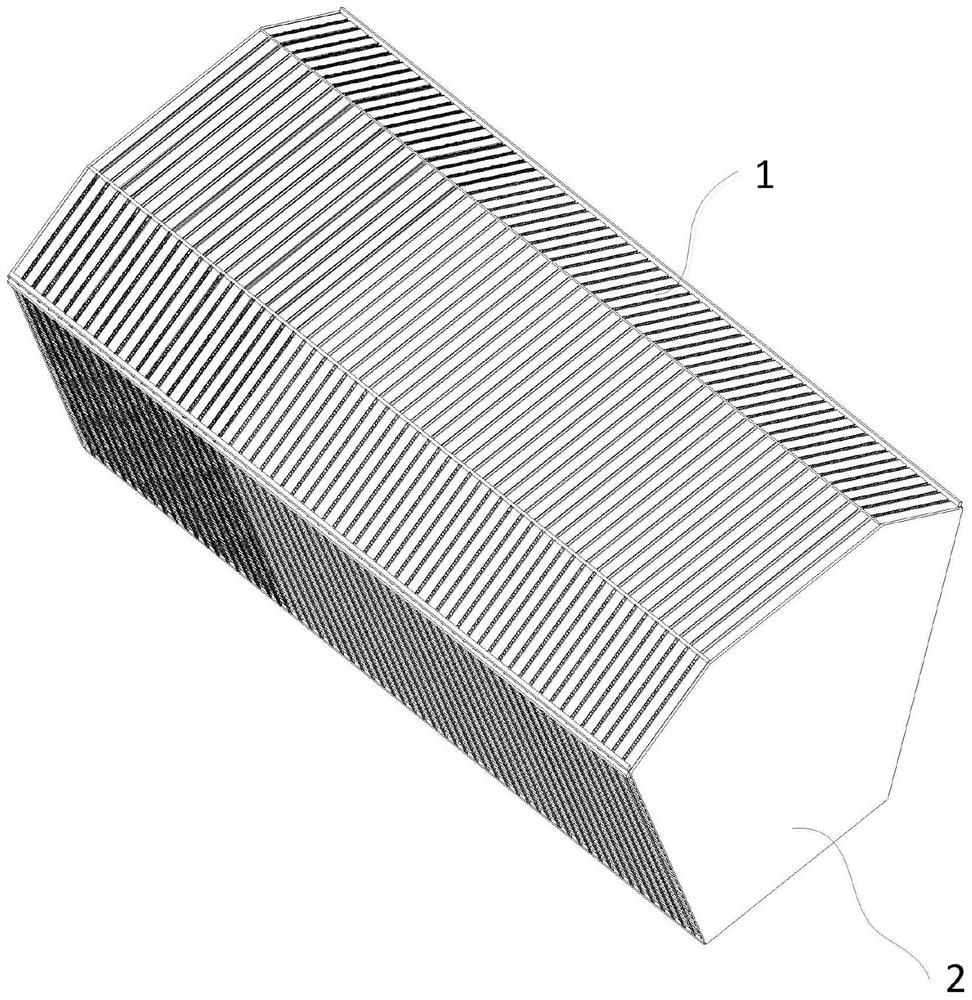

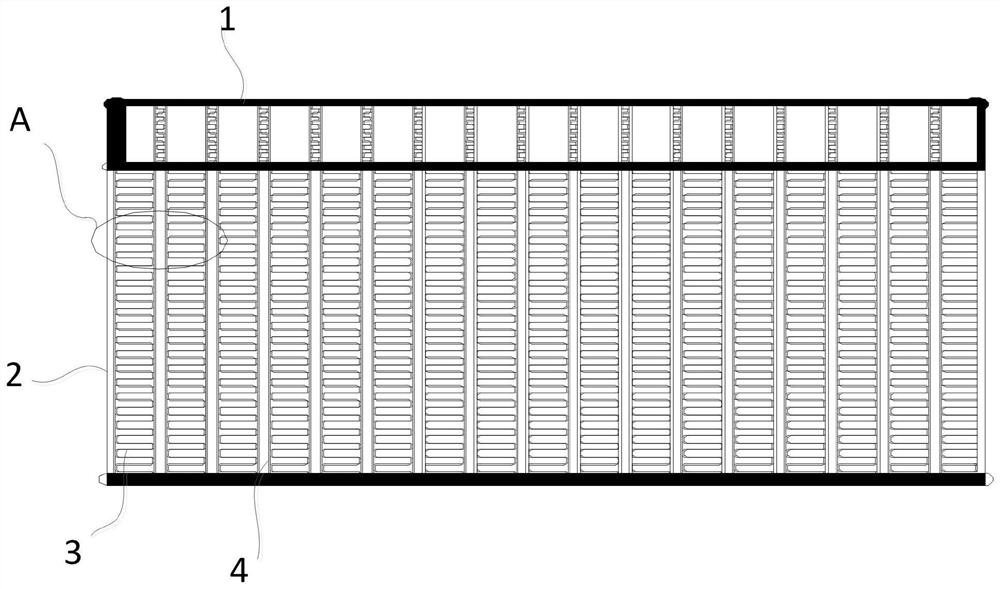

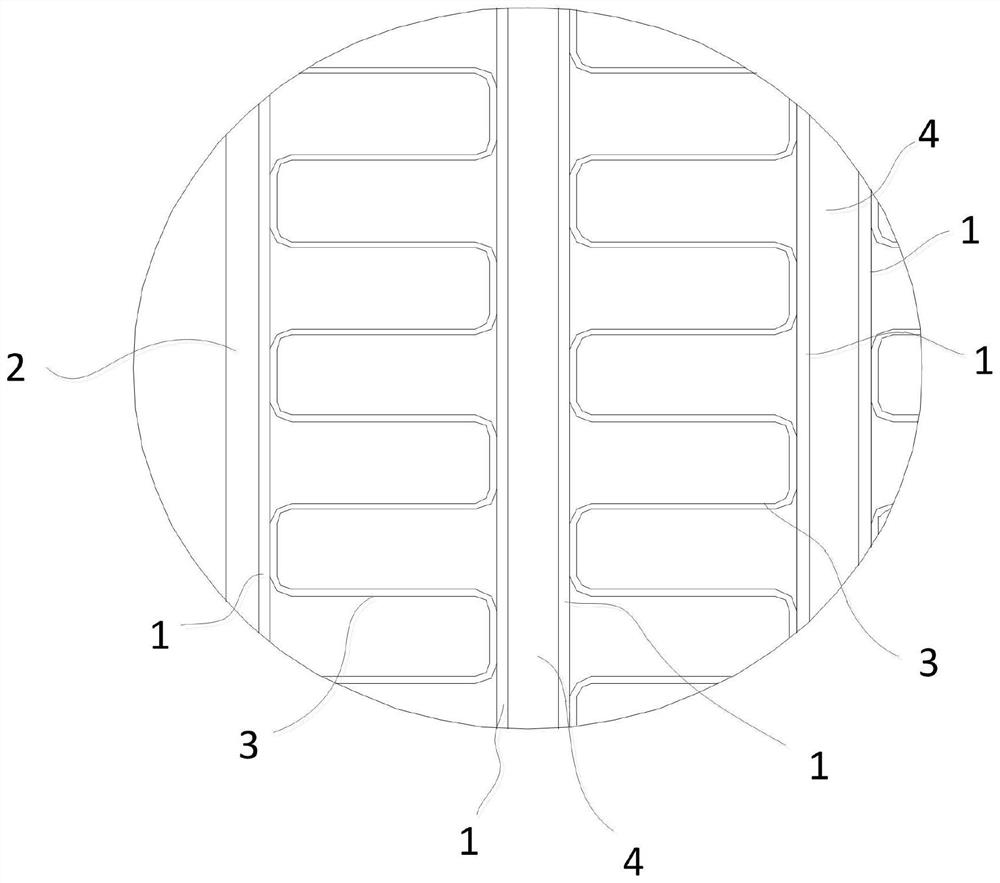

[0025] Example 1, e.g., Figure 1 to Figure 5 As shown, the present embodiment is intended to provide a heat exchanger core with high heat exchange efficiency and can meet the light strength, the aircraft air conditioning system provided in the present embodiment is provided with a plate fin type high efficiency heat exchanger core, comprising a core body, the core body comprises several units stacked against each other structural frame 1 and in the core body on both sides of the end plate 2, the structural frame 1 is provided with a cold circuit fin 3 or a hot circuit fin 4, the structural frame 1 and the cold circuit fin 3 constitute a cold road channel, the structure frame 1 and the hot circuit fin 4 constitute a hot road channel, The cold circuit channel and the hot circuit channel between the staggered stacking setting, i.e., the adjacent two hot circuit channels between the cold road channel, in the present embodiment, a total of 60 layers of hot road channel and 59 layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com