Laser welding method of stainless steel sheet fillet weld and clamp thereof

A technology of laser welding jig and welding method, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of heating, burning, emission electron conditions, arc drift, and variation in the welding area, and achieve good process stability, The clear effect of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

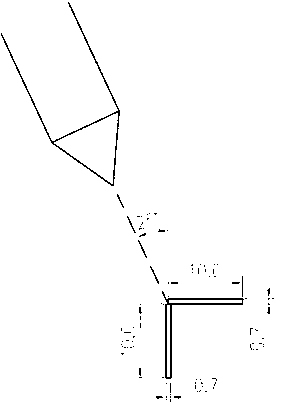

[0029] Take stainless steel sheet material 304, thickness 0.7mm, welding length 10mm as an example.

[0030] The following steps and process parameters are used to make:

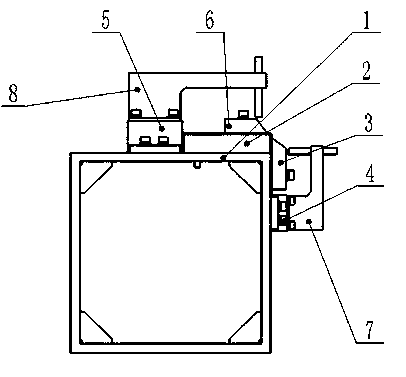

[0031] (1) Two thin plates with a thickness of 0.7mm are fixed by a welding jig with one side of the jig at a horizontal position and the other side at a 90° angle. The jig is made of copper. Because of the high reflectivity of copper, it is not easy to make the back of the thin plate when welding the thin plate. Adhesion with the fixture, the base is made of cast steel;

[0032] (2) Wipe the surface of the stainless steel sheet to be welded with absolute ethanol to remove the oil on the surface;

[0033] (3) Lap the horizontal stainless steel sheet to be welded to two-thirds of the thickness of another vertical stainless steel sheet, and fix the two sheets tightly by adjusting the clamp;

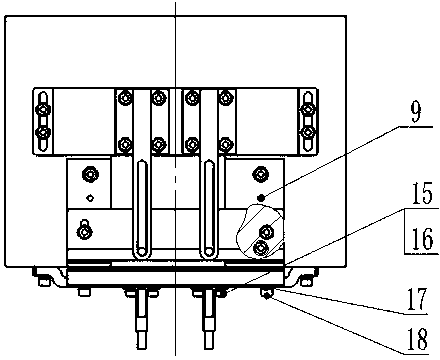

[0034] (4) 4 shielding gas nozzles arranged sequentially in the form of steps on a plane, coaxial protection;

...

Embodiment 2

[0039] As an improvement of the present invention, the CCD sensor is first taught to the robot during the welding operation, and then the parameters are set so that the robot can complete the welding operation instead. After adopting this design, the CCD sensor avoids the error of human eye observation during the teaching process, realizes precise positioning by observing the start and end positions on the computer monitor, and ensures the production efficiency of welding. The rest of the structural features and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0041] As an improvement of the present invention, the parameters are welded according to the following process parameters, the laser output power is 1000w, the welding speed is 2m / min, the shielding gas flow rate is 10L / min, and the defocus amount is +15mm. After adopting this design, the low welding speed makes the weld formation more stable, and the low power avoids welding penetration, but oxidation is easy to occur due to the slow speed. All the other structures and advantages are identical to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com