Steel wire plastic pipe recovery device

A steel wire plastic pipe and recovery device technology, applied in the field of pipe materials, can solve the problems of difficult disposal of waste steel wire plastic pipes, easy safety accidents, low operating efficiency, etc., and achieve low processing labor intensity, less safety accidents, and high operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

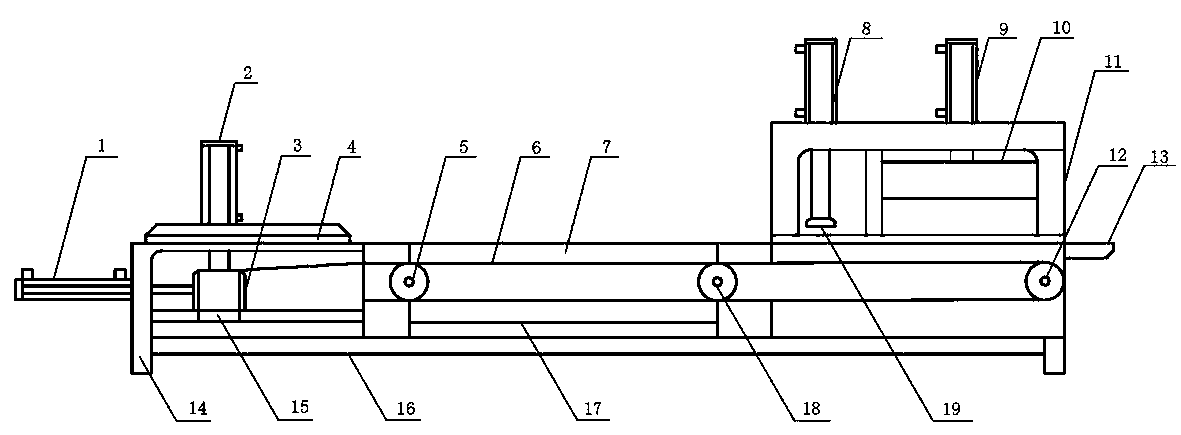

[0009] The present invention is further described in detail in conjunction with the accompanying drawings, so that the public can better grasp the implementation method of the present invention. The specific embodiment of the present invention is: the described steel wire plastic pipe recovery device is composed of telescopic rod 1, hydraulic cylinder 2, compression groove 3, Guide groove 4, front guide wheel 5, conveyor belt 6, electric oven 7, shear cylinder 8, rolling cylinder 9, rolling panel 10, rolling support 11, rear guide wheel 12, feeding platform 13, discharging support 14 , a discharge hole 15, a base 16, a heating wire 17, a power wheel 18, and a shearing knife 19. It is characterized in that one end of the base 16 is provided with a discharge support 14, and the other end of the base 16 is provided with a rolling support 11. An electric oven 7 is arranged in the middle, a guide groove 4 is arranged on the upper end of the discharge support 14, a hydraulic cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com