Efficient loading and unloading system and process for harbor containers

A loading and unloading system and container technology, applied to storage devices, transportation and packaging, trolley cranes, etc., to achieve the effects of ensuring loading and unloading efficiency, improving transportation safety, and improving stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

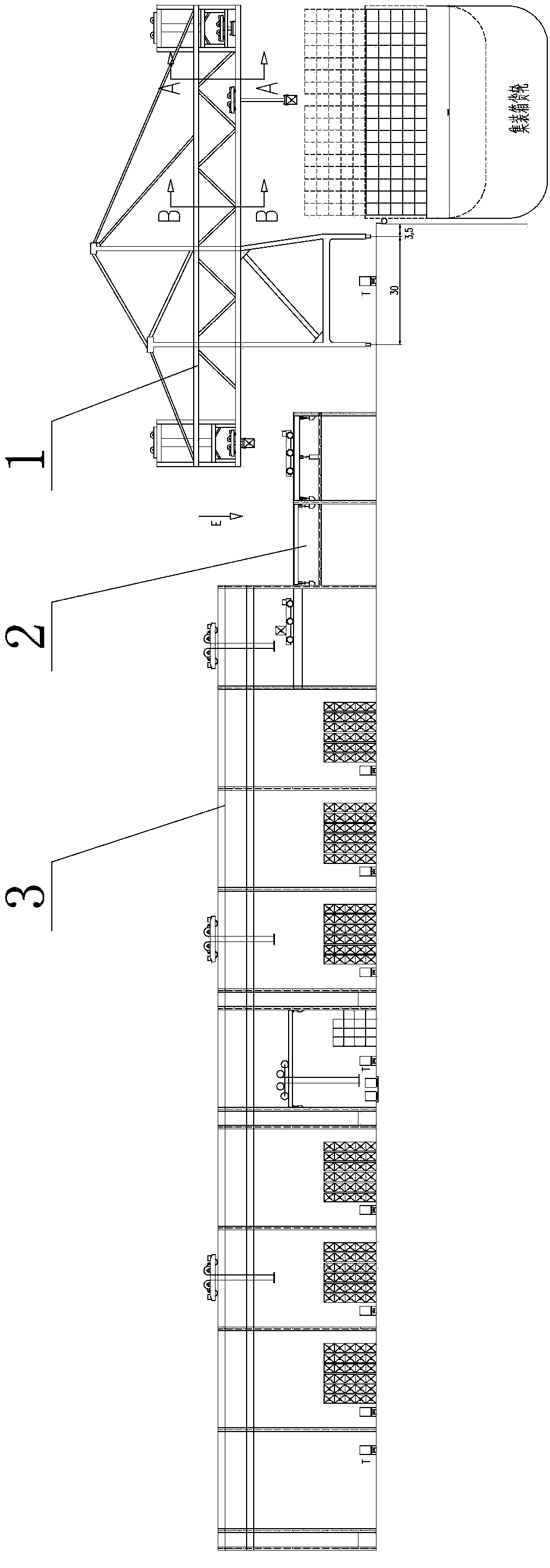

[0051] Embodiment 2 of the present invention, such as figure 1 As shown, a port container high-efficiency loading and unloading system includes a double-deck quay bridge 1 with an elevator, a ferry bridge 2 and a steel structure yard bridge 3, the ferry bridge 2 is connected with the steel structure yard bridge 3, and the double-deck quay bridge 1 with an elevator The tail of is located above the ferry bridge 2.

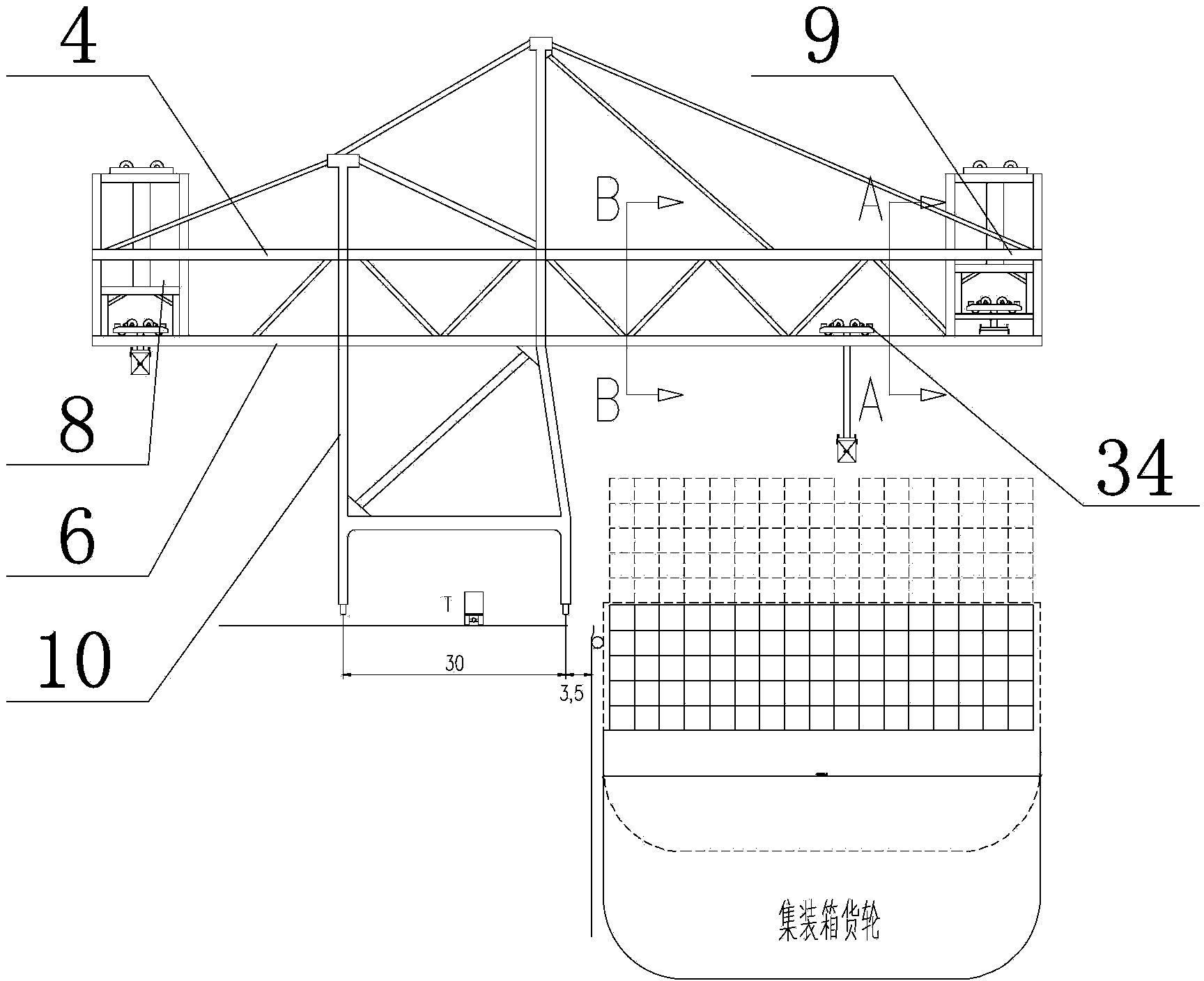

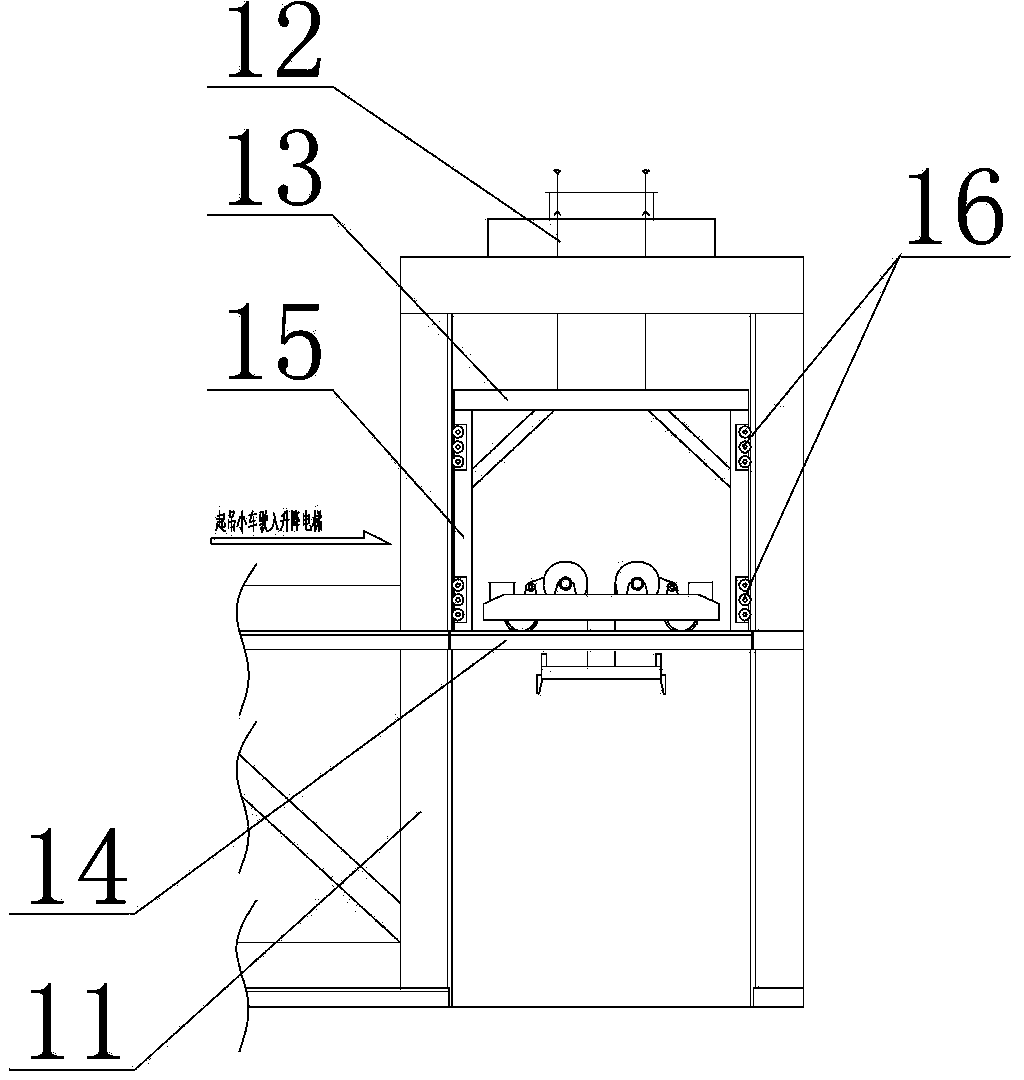

[0052] Such as figure 2 As shown, the double-deck quay bridge 1 with elevator includes gantry-type outriggers 10, the upper walking girder 4, the upper walking track 5, the lower walking girder 6, the lower walking track 7, the elevator A8, the elevator B9 and the crane lifting The trolley 34, the upper walking girder 4 and the lower walking girder 6 are all fixedly installed on the gantry type outrigger 10, the lower walking girder 6 is arranged below the upper walking girder 4, the upper walking track 5 is arranged on the upper walking girder 4, and the lower wal...

Embodiment 4

[0081] Embodiment 4 of the present invention, a high-efficiency loading and unloading system for port containers, includes a double-deck quay bridge 1 with an elevator, a ferry bridge 2 and a steel structure yard bridge 3, the ferry bridge 2 is connected with the steel structure yard bridge 3, and the double-deck bridge with an elevator The tail of the landing bridge 1 is located above the ferry bridge 2 .

[0082] The double-deck quay crane with elevator includes gantry-type outriggers, upper-level walking track, lower-level walking track, lift elevator A, lift lift B and lifting trolley for the quayside bridge. The inner sides of the two solid web beams are equipped with upper and lower walking tracks, the upper walking track is set above the lower walking track, and the lift A and lift B are respectively set on the two solid web beams. ends. The interior of the two solid web beams is provided with fixed-space reinforcing ribs to ensure the rigidity of the solid web beams. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com