High-impact anti-aging antistatic PP (Polypropylene) polymer as well as preparation method and application thereof

An anti-aging and anti-static technology, which is applied in the field of high-impact anti-aging anti-static PP polymer and its preparation, can solve the problems of unsatisfactory effect, failure to meet the anti-static standard of precision instruments, aerospace vehicle interiors, etc., and achieve good results. Use effect, prevention of oxidative decomposition, high impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

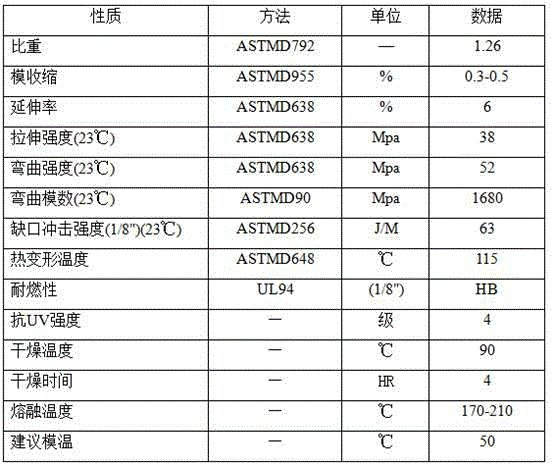

Embodiment 1

[0038] This embodiment provides a high impact and aging resistance antistatic PP polymer. Its raw material formula is made up of each component of following parts by weight:

[0039] Antioxidant 1 0.3 part;

[0040] Antioxidant 2 0.5 parts

[0041] Toughener POE8150 4 parts;

[0042] Ultraviolet absorber UV531 0.6 part;

[0043] PP 88 parts;

[0044]Antistatic agent 1 0.9 part;

[0045] Antistatic agent 2 2.4 parts;

[0046] Antistatic agent 3 3.3 parts

[0047] The toughening agent POE8150 refers to POE8150 produced by U.S. Dow, the antioxidant 1 is commercially available antioxidant 168, the antioxidant 2 is commercially available antioxidant 1010, and the antistatic Agent 1 is triethanolamine, the antistatic agent 2 is JWKJD-9525 of Wuxi Juwang Plastic Materials Co., Ltd., and the antistatic agent 3 is SH-105 produced by Shanghai Jingwei Chemical Co., Ltd.

[0048] The above-mentioned antioxidant 1, antioxidant 2, toughening agent, ultraviolet absorber, and PP are a...

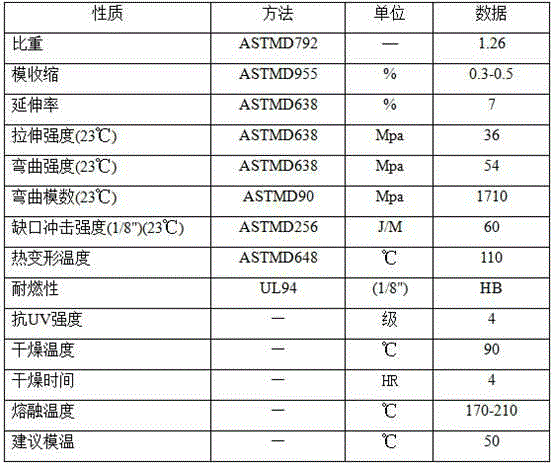

Embodiment 2

[0059] This embodiment provides a high impact and aging resistance antistatic PP polymer. Its raw material formula is made up of each component of following parts by weight:

[0060] Antioxidant 1 0.1 part;

[0061] Antioxidant 2 0.8 parts

[0062] Toughener POE8150 1 part;

[0063] Ultraviolet absorber UV531 0.7 parts;

[0064] PP 92.3 parts;

[0065] Antistatic agent 1 0.6 parts;

[0066] 2 to 3 parts of antistatic agent;

[0067] Antistatic agent 3 1.5 parts

[0068] The toughening agent POE8150 refers to POE8150 produced by U.S. Dow, the antioxidant 1 is commercially available antioxidant 168, the antioxidant 2 is commercially available antioxidant 1010, and the antistatic Agent 1 is triethanolamine, the antistatic agent 2 is JWKJD-9525 of Wuxi Juwang Plastic Materials Co., Ltd., and the antistatic agent 3 is SH-105 produced by Shanghai Jingwei Chemical Co., Ltd.

[0069] The above-mentioned antioxidant 1, antioxidant 2, toughening agent, ultraviolet absorber, and ...

Embodiment 3

[0080] This embodiment provides a high impact and aging resistance antistatic PP polymer. Its raw material formula is made up of each component of following parts by weight:

[0081] Antioxidant 1 0.5 part;

[0082] Antioxidant 2 0.3 parts

[0083] Toughening agent POE8150 5 parts;

[0084] Ultraviolet absorber UV531 0.4 parts;

[0085] PP 86.5 parts;

[0086] Antistatic agent 1 1.3 parts;

[0087] Antistatic agent 2 2 parts;

[0088] Antistatic agent 3 4 parts

[0089] The toughening agent POE8150 refers to POE8150 produced by U.S. Dow, the antioxidant 1 is commercially available antioxidant 168, the antioxidant 2 is commercially available antioxidant 1010, and the antistatic Agent 1 is triethanolamine, the antistatic agent 2 is JWKJD-9525 of Wuxi Juwang Plastic Materials Co., Ltd., and the antistatic agent 3 is SH-105 produced by Shanghai Jingwei Chemical Co., Ltd.

[0090] The above-mentioned antioxidant 1, antioxidant 2, toughening agent, ultraviolet absorber, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com