Apparatus and method used for radar online detection of surface shape of blast furnace burden surface

A blast furnace material surface and surface shape technology, applied in the field of metallurgy, can solve the problems of increasing difficulty in analyzing the distribution of the material surface in the furnace, not being able to spread over the material surface on the top of the furnace, and unable to guarantee the accuracy, etc., so as to ensure production safety, optimize operation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

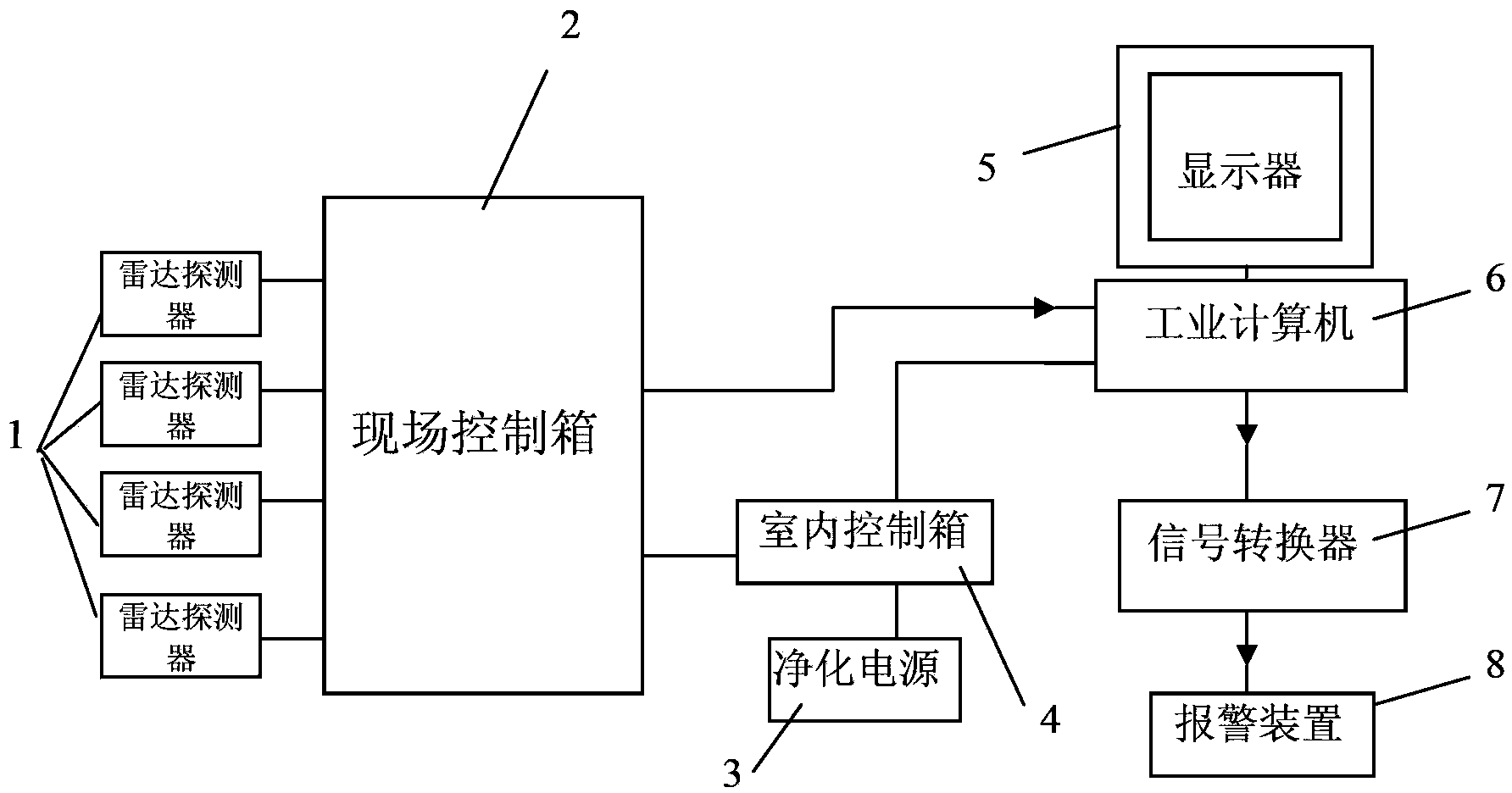

[0028] Such as figure 1 Shown is the radar on-line detection device for the surface shape of the blast furnace charge surface of the present invention, wherein 1 is a radar detector, 2 is an on-site control box, 3 is a purification power supply, 4 is an indoor control box, 5 is a display, and 6 is an industrial computer , 7 is a signal converter, and 8 is an alarm device. The radar detector 1 is connected to the industrial computer 6 through the field control box 2, the field control box 2 and the indoor control box 4 are connected in series to form another branch and connected to the industrial computer 6, the industrial computer 6 is connected to the display 5, and the purification power supply 3 is connected to the indoor The control box 4 is connected, and the alarm device 8 is connected with the industrial computer 6 through the signal converter 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com