Soft skimming plug and manufacturing method thereof

A manufacturing method and a technology for a slag blocking plug, which are applied in the metallurgical field, can solve the problems of unsatisfactory slag blocking effect of the slag blocking plug, erosion of the steel outlet, etc., and achieve the effects of adjusting the opening time, reducing the amount of slag, and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

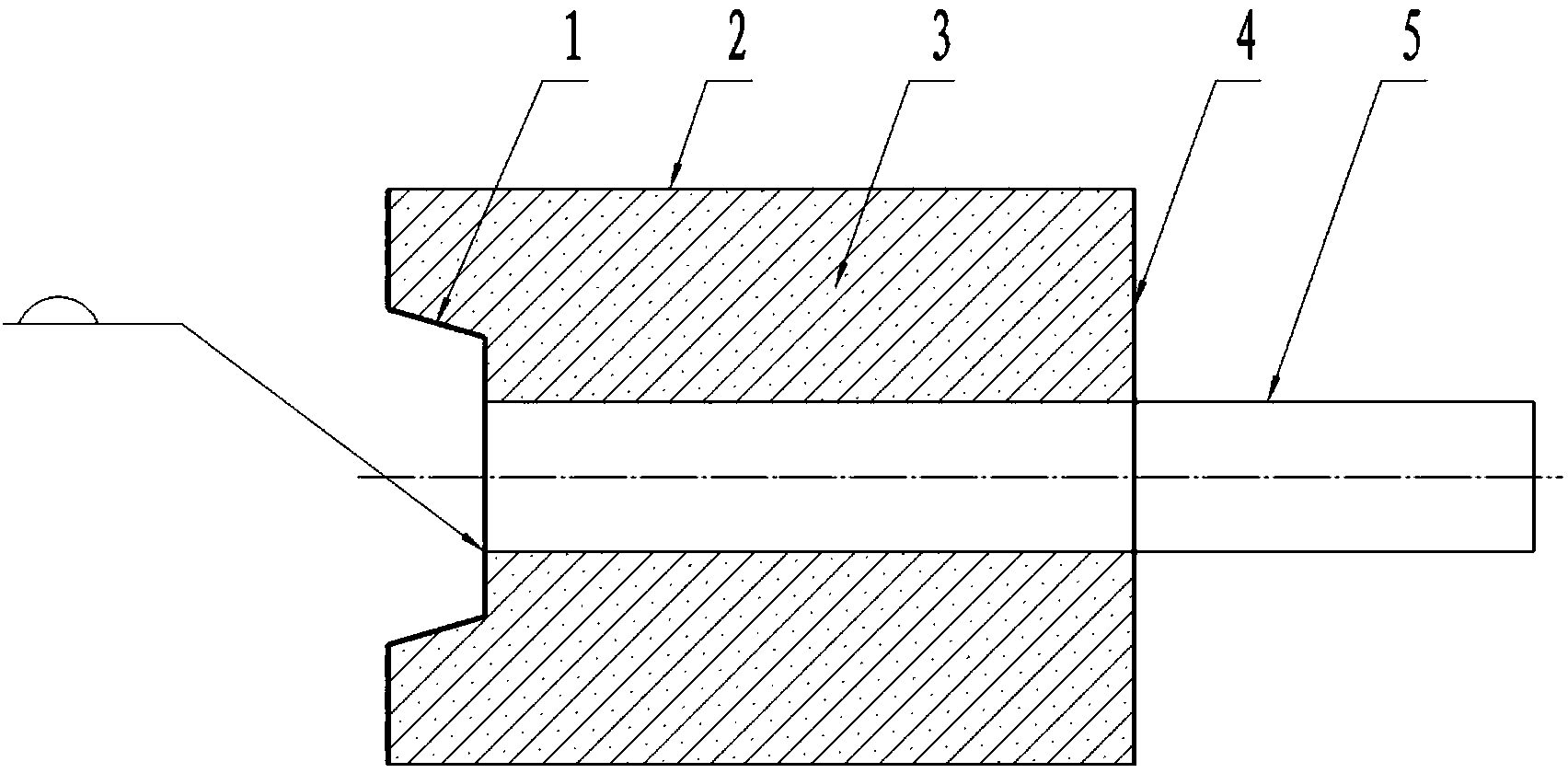

[0024] The present invention will be further described now in conjunction with accompanying drawing.

[0025] refer to figure 1 , the soft slag stopper of the present invention includes a central steel pipe 5, a cold-rolled stamped steel sheet 1, a compressible movable cold-rolled stamped steel sheet 4, a refractory plastic 3 and a plastic film 2; wherein, the cold-rolled stamped steel sheet 1 Welded on the front end of the central steel pipe 5, the compressible movable cold-rolled stamped steel sheet 4 is sleeved on the rear end of the central steel pipe 5 and can slide along the central steel pipe 5, and the cold-rolled stamped steel sheet 1 1. A fire-resistant plastic 3 is arranged between the compressible movable cold-rolled stamping steel sheets 4, and the plastic film 2 is wrapped outside the fire-resistant plastic 3.

[0026] Each part of the soft slag stopper of the present invention will be further described below. The refractory plastic 3 is an amorphous refractory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com