Hood-type annealing furnace device

A bell-type annealing furnace and bell-type furnace technology, applied in the direction of bell-type furnaces, furnaces, furnace types, etc., can solve the problems of complex protective gas preparation, heating and transportation processes, heat not being used, and long heat treatment time. Achieve the effect of improving heat transfer efficiency, improving thermal efficiency and enterprise economic benefits, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

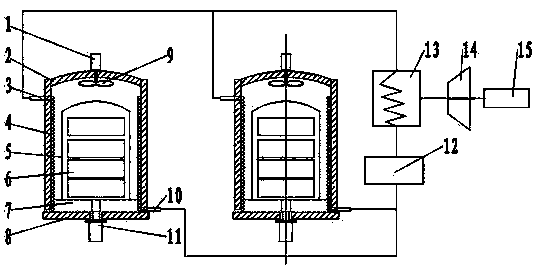

[0014] Bell type annealing furnace device of the present invention such as figure 1 As shown, it consists of 2 bell furnaces, heat transfer oil pump 12, steam generator 13, steam turbine 14 and generator 15. The bell-type furnace includes a hearth 8, a heating mantle, a cooling mantle 2 and an inner cover 5. A support plate 7 is arranged on the upper part of the hearth, and a diversion fan 11 is arranged at the bottom of the hearth. The top of cooling cover 2 is provided with cooling fan 1, and cooling fan is connected with fan 9. The cooling cover is provided with a coil tube 4, and the coil tube is wound on the inner wall of the cooling cover 2, and the coil tube and the jacket are respectively provided with a heat transfer oil outlet 3 and a heat transfer oil inlet 10. The outlet of the heat transfer oil is located at the upper part of the cooling cover, and the inlet of the heat transfer oil is located at the lower part of the cooling cover. The steam generator is a snak...

Embodiment 2

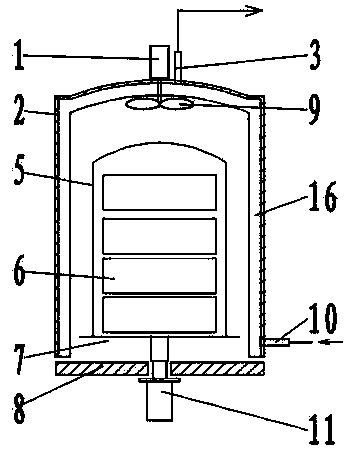

[0017] Another embodiment of this embodiment is as figure 2 As shown, the cooling cover is provided with a jacket 16, the jacket is located on the inner wall and top of the cooling cover, the heat transfer oil outlet 3 of the jacket is located at the top of the cooling cover, and the heat transfer oil inlet 10 is located at the bottom of the cooling cover. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com