Reverse pulling device for pulling construction of long-span steel truss beams

A technology of dragging device and steel truss girder, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem that the longitudinal stability of steel truss girder members is not easy to maintain, the traffic safety under the bridge is hidden, and the dragging and rectification are difficult. problems, to achieve the effect of smooth and smooth motion characteristics, shortening the dragging time, and quick and convenient installation and dismantling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

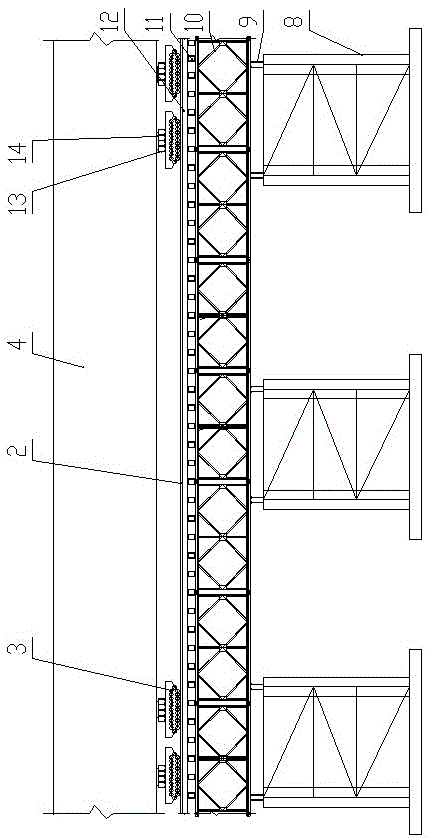

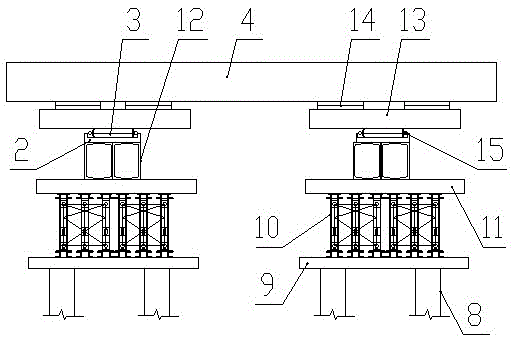

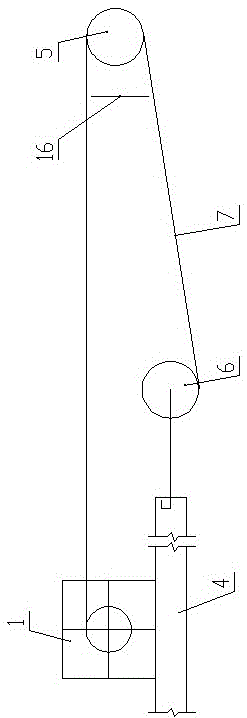

[0061] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the reverse pulling device used for the pulling construction of large-span steel truss girder includes a temporary support and a hoist 1. The temporary support is provided with a slideway 2 whose cross section is in the shape of a groove. The crawler-type transporter 3 moved by the road 2, the steel truss girder 4 is set on the crawler-type transporter 3, the hoist 1 is set on the steel truss girder 4, the upper part of the front end of the temporary support is provided with a fixed pulley block 5, and the hoist 1 is wound on The traction rope 7 bypasses the fixed pulley block 5 and is connected to the front end of the steel truss beam 4 through a movable pulley block 6 .

[0062] The temporary support includes a steel pipe column 8, an I-beam distribution beam 9, a Bailey beam 10, a shaped steel sleeper 11 and a drag track beam 12, which are arranged in sequence from bottom to top. Bailey Beam 10 on.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com