A construction method of anti-damage aluminum alloy door and window frames

A technology of aluminum alloy doors and windows and construction method, applied in the direction of window/door frame, building material processing, construction, etc., can solve problems such as water seepage, corrosion, inconsistent thickness of thermal insulation board, etc., achieve obvious construction convenience, prevent Contamination and damage, the effect of improving ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0025] A construction method for an anti-damage aluminum alloy door and window frame, the construction steps are:

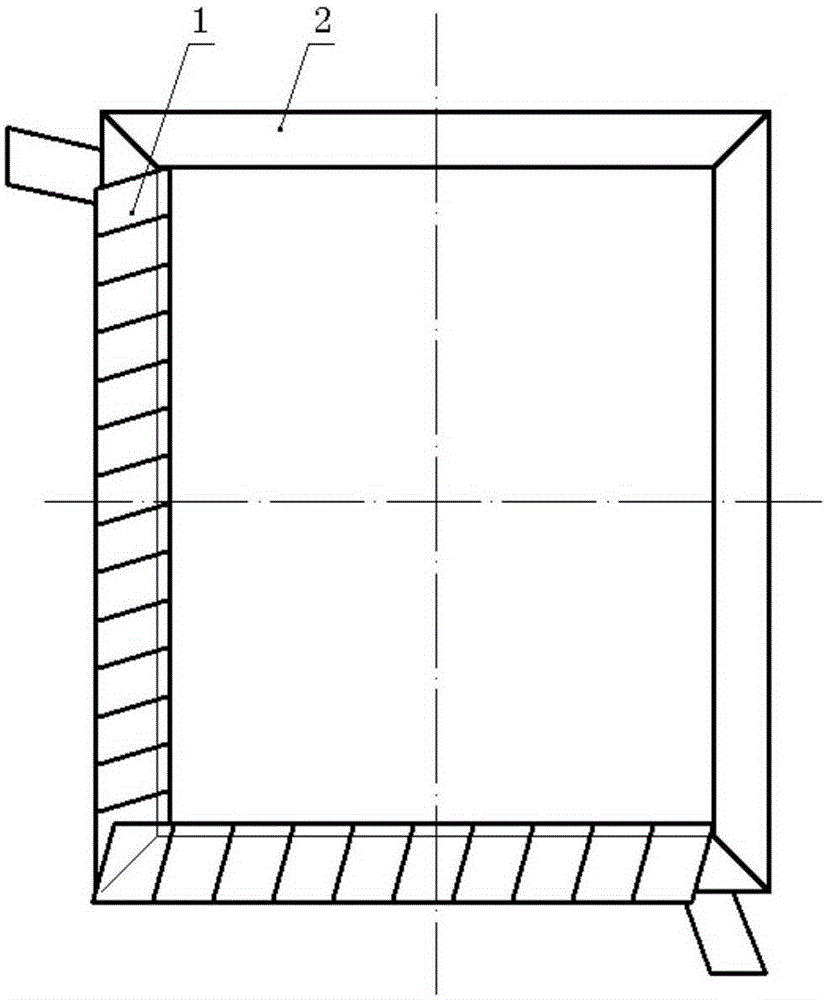

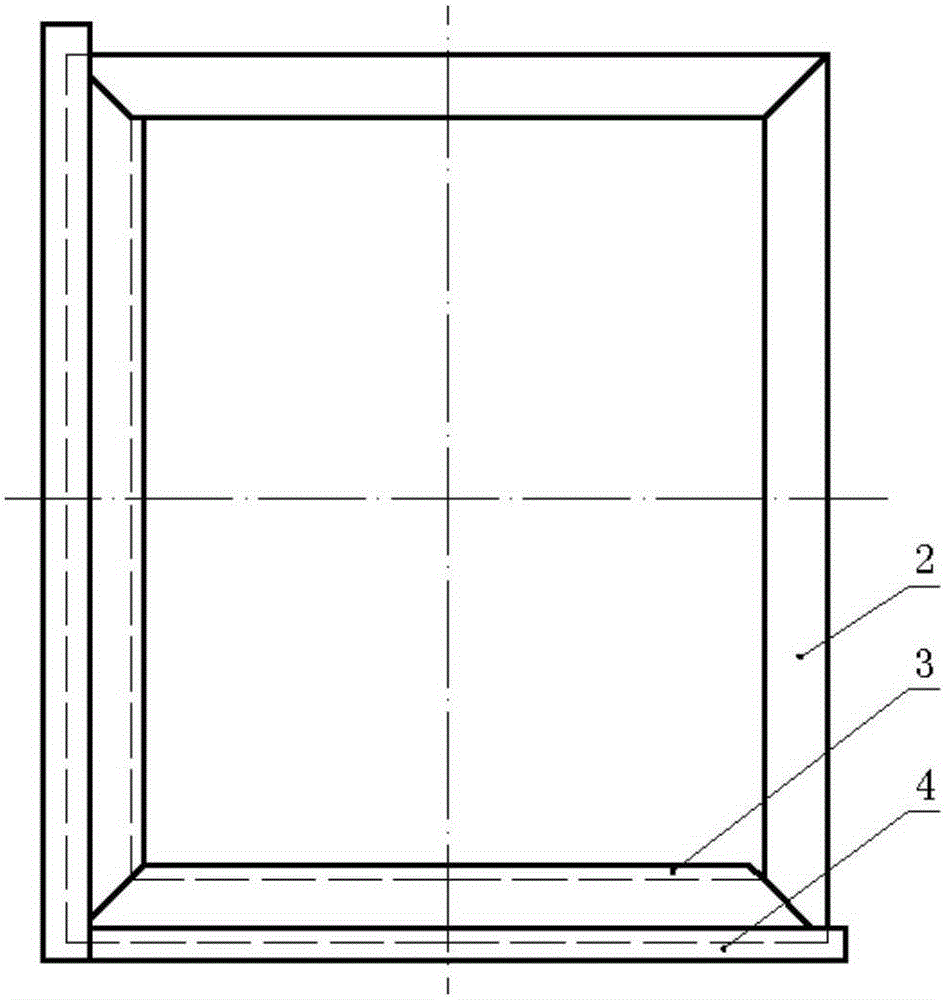

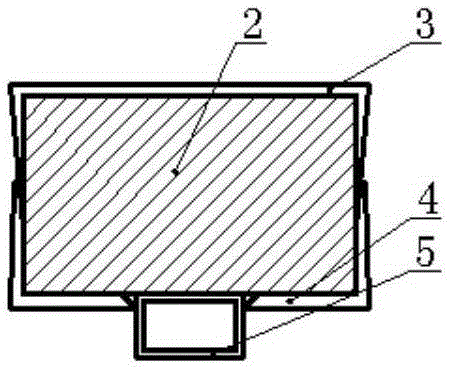

[0026] ⑴Construction at the installation location, installing steel sub-frame 5 on concrete doors and windows, laying insulation boards and plastering on doors and windows;

[0027] ⑵Preparation of the outer frame: a. Peel off the outer packaging tape wrapped around the outer frame; When the frame is transported and stacked, it plays the role of anti-vibration and anti-damage; c. A protective film layer is attached to the inner ring side of the outer frame and the inner and outer end faces of the outer frame. The protective tape can be used for the protective film layer. The outer pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com