Light weight thermal insulation dry-mixed mortar

A dry-mixed mortar and light-weight technology, applied in the field of dry-mixed mortar, can solve the problems of easy pulverization, flammability of polystyrene particles, and large water absorption of expanded perlite, so as to enhance the bonding force and improve the thermal insulation performance of the wall , good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

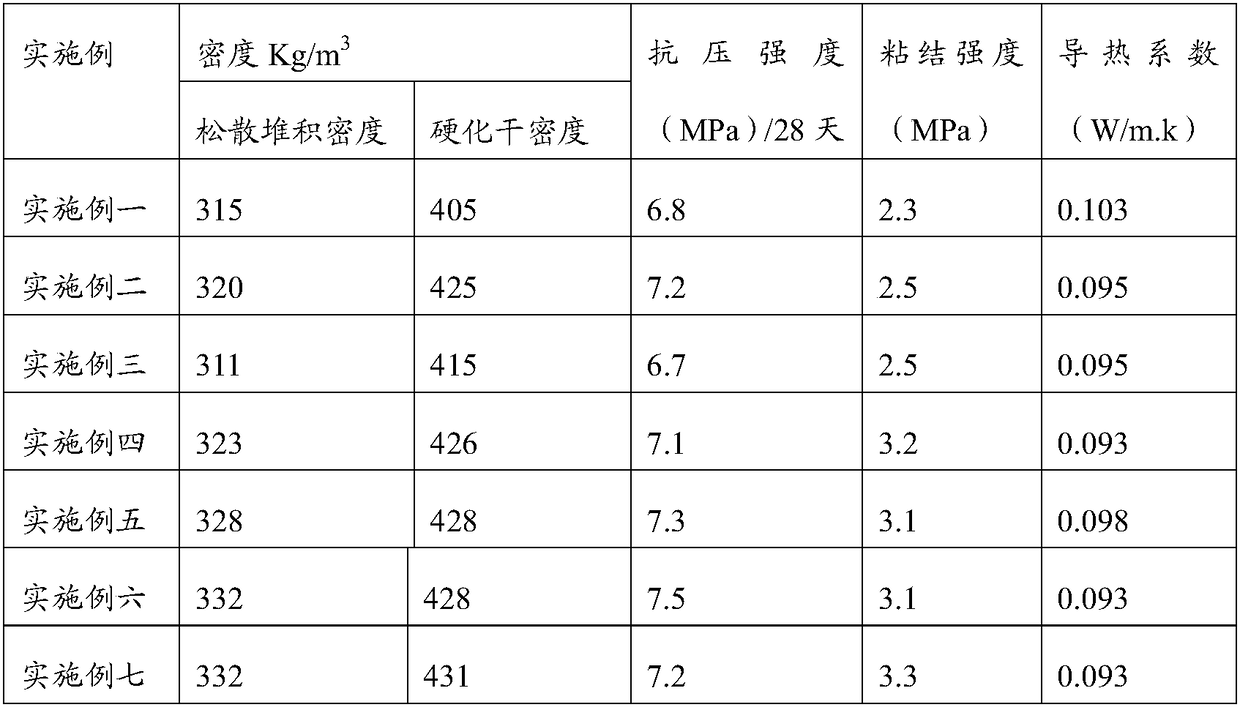

Examples

Embodiment 1

[0027] The lightweight thermal insulation dry powder mortar of the present embodiment includes the following raw materials in parts by weight: 20 parts of gel material, 60 parts of lightweight aggregate and 0.5 part of high-performance polymer additive; the gel material is composed of the following parts by weight of raw materials: powder 20 parts of coal ash and 60 parts of cement; the lightweight aggregate is turpentine vitrified microspheres; the high-performance polymer additive includes the following raw materials: organic silicon resin, hydroxypropyl methylcellulose ether, ethylene-acetic acid Ethylene copolymer dry powder, polycarboxylate superplasticizer dry powder and early strength agent. The weight ratio of the hydroxypropyl methylcellulose ether, ethylene-vinyl acetate copolymer dry powder and early strength agent is 1:2:1.

Embodiment 2

[0029] The lightweight thermal insulation dry powder mortar of the present embodiment includes the following raw materials in parts by weight: 40 parts of gel material, 80 parts of lightweight aggregate and 1.5 parts of high-performance polymer additive; the gel material is composed of the following raw materials in parts by weight: powder 40 parts of coal ash and 80 parts of cement; the lightweight aggregate is turpentine vitrified microspheres; the high-performance polymer additive includes the following raw materials: organic silicon resin, hydroxypropyl methylcellulose ether, ethylene-acetic acid Ethylene copolymer dry powder, polycarboxylate superplasticizer dry powder and early strength agent. The weight ratio of the hydroxypropyl methylcellulose ether, ethylene-vinyl acetate copolymer dry powder and early strength agent is 1:3:1.

Embodiment 3

[0031] The lightweight thermal insulation dry powder mortar of the present embodiment includes the following raw materials in parts by weight: 30 parts of gel material, 70 parts of lightweight aggregate and 1 part of high-performance polymer additive; the gel material is composed of the following parts by weight of raw materials: powder 30 parts of coal ash and 70 parts of cement; the lightweight aggregate is turpentine vitrified microspheres; the high-performance polymer additive includes the following raw materials: organic silicon resin, hydroxypropyl methylcellulose ether, ethylene-acetic acid Ethylene copolymer dry powder, polycarboxylate superplasticizer dry powder and early strength agent. The weight ratio of the hydroxypropyl methyl cellulose ether, ethylene-vinyl acetate copolymer dry powder and early strength agent is 1:2.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com