Drifting-proof rivet bolt and connecting structure

A technology of riveting bolts and displacement, applied in the direction of connecting components, bolts, rivets, etc., which can solve the problems of sagging connection holes, safety hazards of de-soldering, and difficult work, so as to increase the connection strength, meet the seismic requirements, and save installation labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

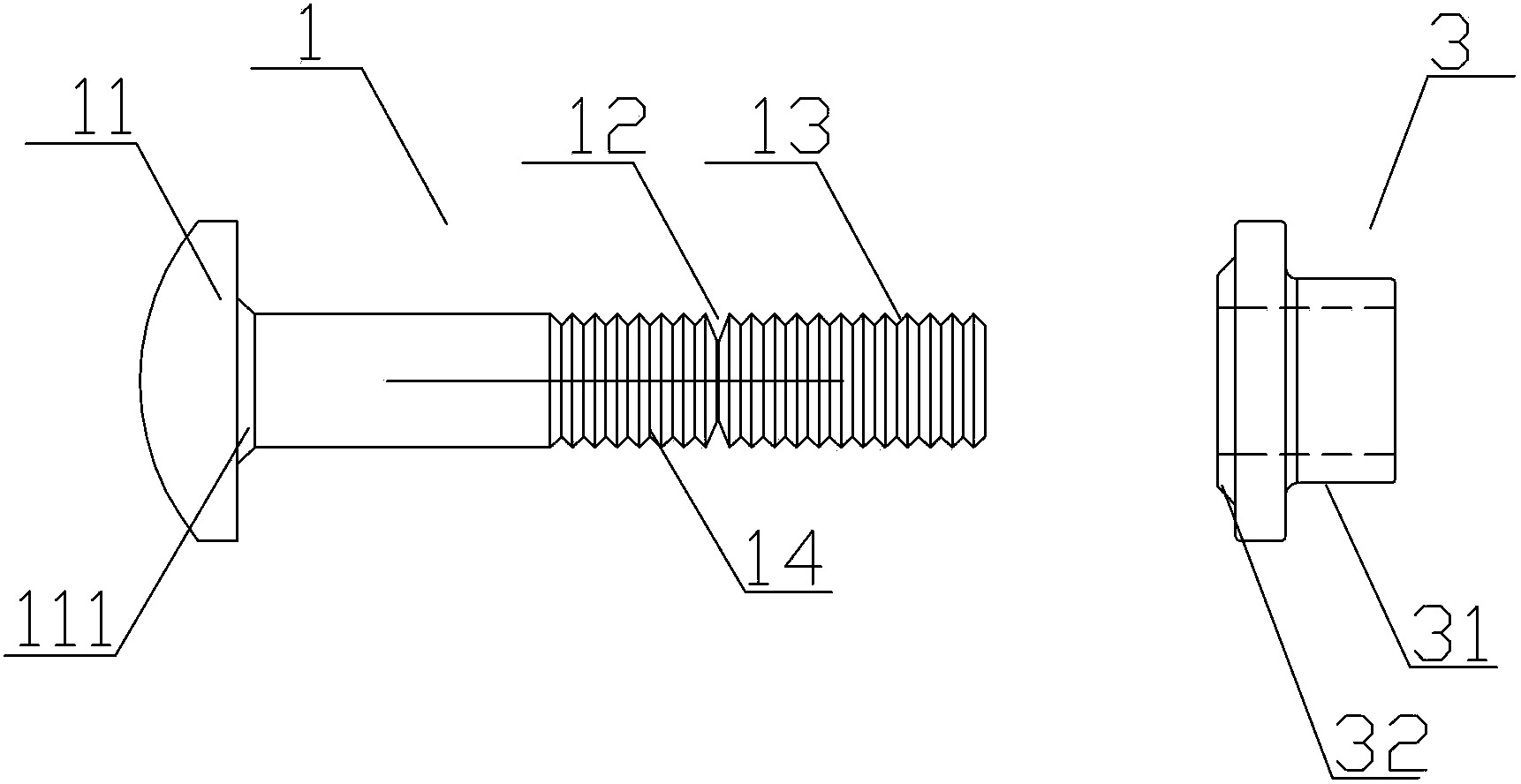

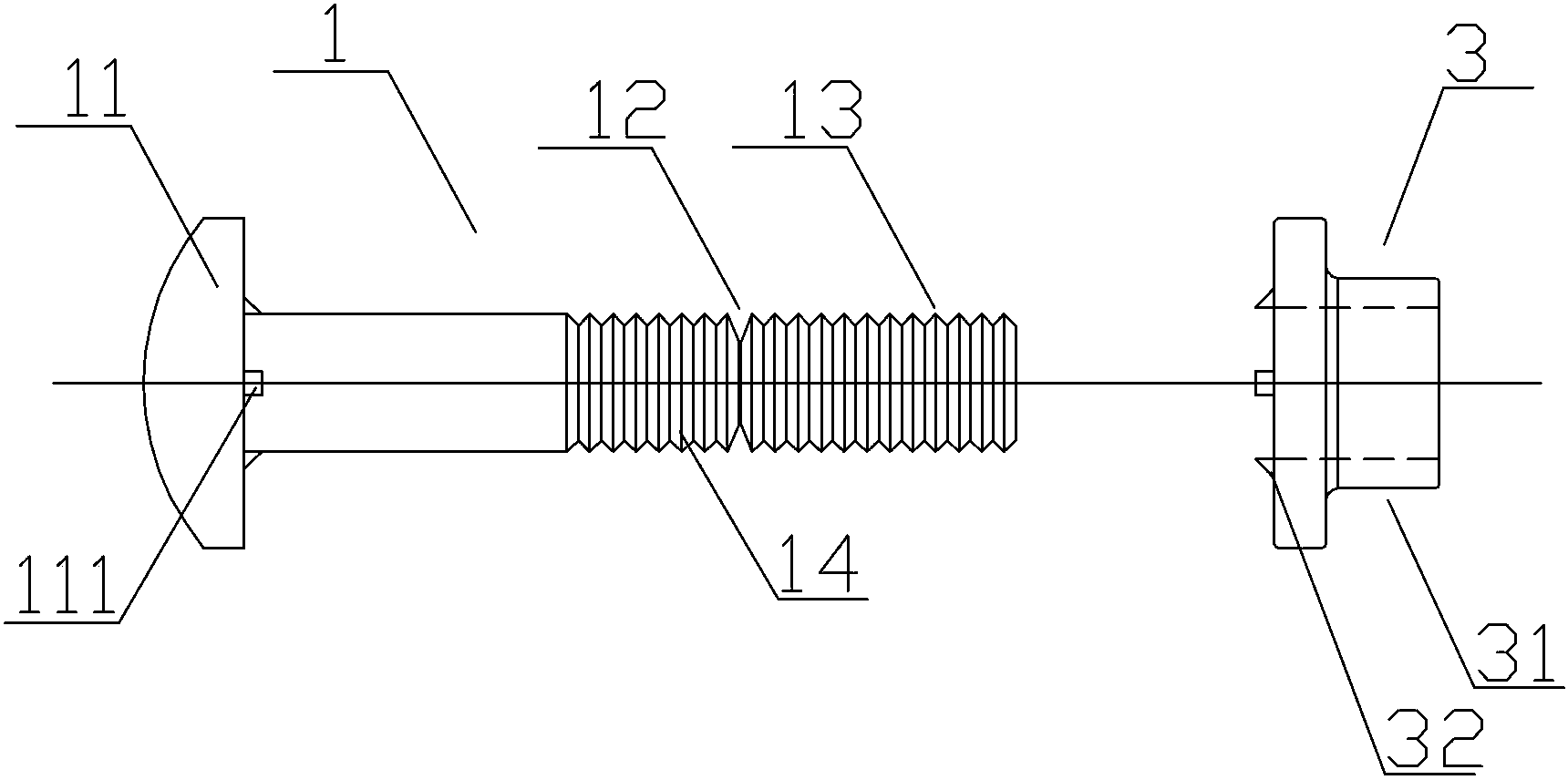

[0038] Example 1, with reference to the attached figure 1 , 3 , 5

[0039] An anti-displacement riveting bolt provided by the present invention includes a metal riveting rod 1, the inner end of the metal riveting rod is provided with a convex head 11, the outer side of the metal riveting rod 1 has a breaking part 12, and there are tools and tools outside the breaking part. The connected connecting section 13; the rivet bolt is also provided with a fastening sleeve 3, and the fastening sleeve 3 is located on the outer side of the connected piece 100. The connected piece 100 can be a plate, and the metal rivet The rod 1 has an anti-loosening riveting section 14 corresponding to the fastening sleeve 3, and the anti-loosening riveting section 14 is made with anti-loosening, such as concave, convex, ring, annular groove, etc., so that the anti-loosening is fastened The segment 14 has an uneven surface. The inner hole of the fastening sleeve 3 is slightly larger than the anti-r...

Embodiment 2

[0057] Example 2, refer to figure 2 .

[0058] This embodiment is basically the same as Embodiment 1, except that the convex rings 32 and 111 of Embodiment 1 are changed to the plurality of protrusions 32 and 111 arranged in the circumferential direction of this embodiment, and their shapes can be dot-shaped or block-shaped. , the function of the protrusion 32 in this embodiment is the same as that of the convex ring 32 in the first embodiment, and the function of the protrusion 111 in this embodiment is the same as that of the convex ring 111 in the first embodiment. There is a tooth pattern matching the tooth pattern in the hole wall of the hole for the metal riveting rod on the connected piece and the hole wall of the hole for the metal riveting rod on the part to be connected with the connecting piece. The tooth pattern that matches the internal tooth pattern. figure 2 , unless otherwise stated, other figure 1 The reference numerals with the same reference numerals re...

Embodiment 3

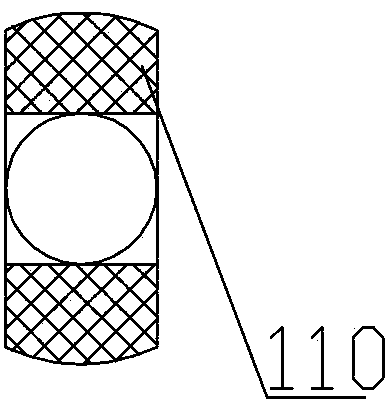

[0059] Example 3, refer to image 3 , 4 .

[0060] In addition, this embodiment is basically the same as Embodiments 1 and 2, except that the convex ring or protrusion 32 is no longer provided, but the following structure is retained:

[0061] The front end surface of the fastening sleeve also has a concave-convex positioning configuration 33 that matches the outer surface of the connected piece. The positioning configuration produces a non-slip fit on the outer surface of the connected piece and the front end surface of the fastening sleeve to further prevent the connected piece from loosening and displace. Anti-slip configuration; the hole through which the metal riveting rod passes through the connected piece is a long hole or a round hole or a long groove, so that the system applying the present invention has the function of compensating for position changes or errors.

[0062]The rear end surface of the male head also has a concave-convex positioning configuration 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com