Solar high-efficient spraying and cooling system

A technology of refrigeration system and solar energy, applied in refrigerators, refrigeration and liquefaction, machines using refrigerant evaporation, etc., can solve the problems of complex structure, unfavorable large-scale promotion, low efficiency of solar jet refrigeration system, etc., and achieve high discharge temperature , the effect of large compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

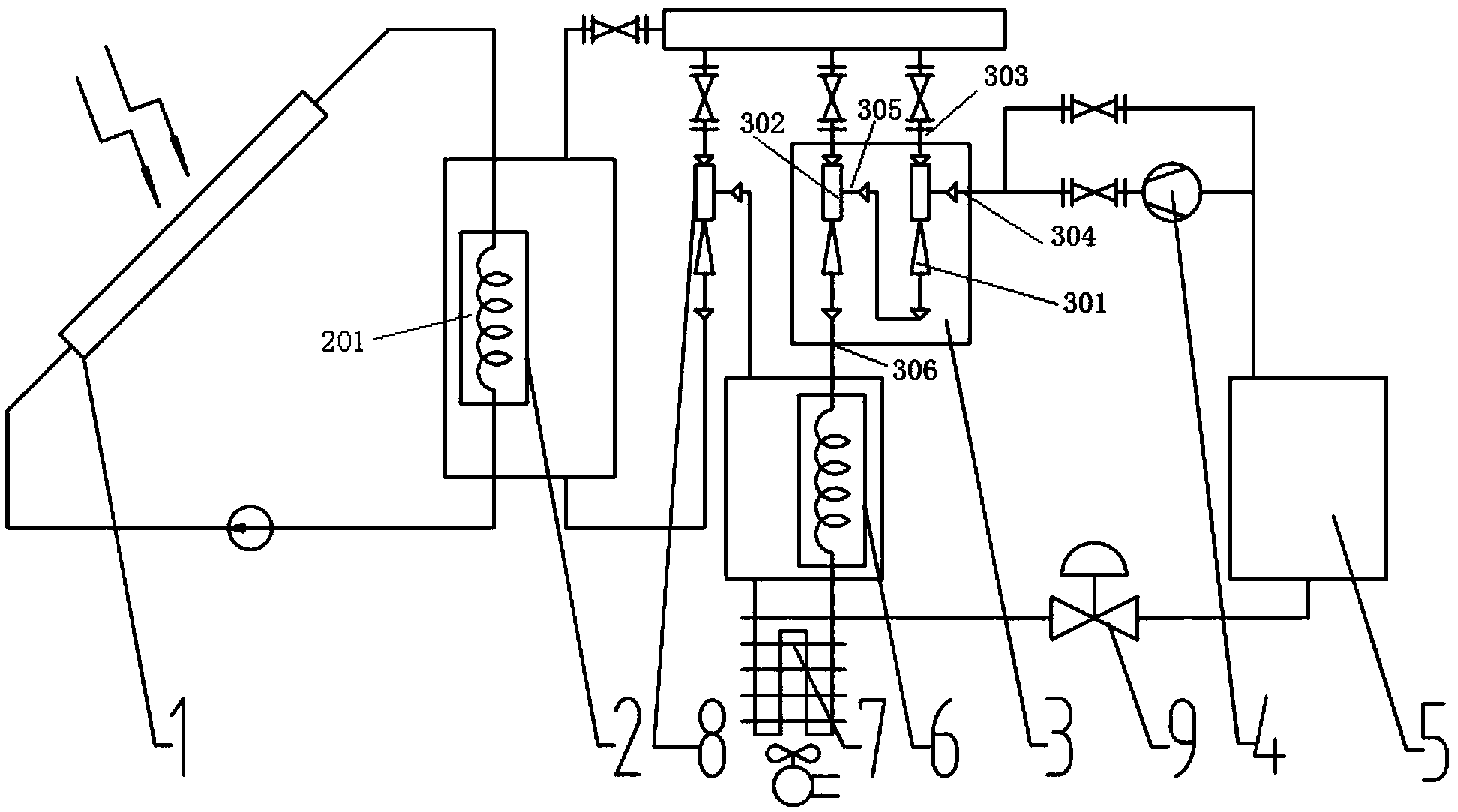

[0023] refer to figure 1 , a solar high-efficiency jet refrigeration system, the system consists of a solar collector 1, a steam generator 2, a secondary ejector 3, a supercharger 4, an evaporator 5, a regenerator 6, a gas condenser 7, and a gas- Liquid injector 8, expansion valve 9 and several valves and pipelines etc. composition.

[0024] The cavity of the steam generator 2 is filled with refrigerant, and the refrigerant is coated with a heat exchanger 201. The heat exchanger 201 and the solar collector 1 form a closed loop, and the refrigerant absorbs the energy of the circulating hot water of the solar collector. After that, a high-temperature and high-pressure refrigerant vapor is formed,

[0025] The two-stage ejector 3 includes a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com