Method for cleaning and purifying sulfur-containing tail gases

A tail gas cleaning and tail gas technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of rapid diffusion of unfavorable tail gas, low desulfurization efficiency of activated carbon, unstable process operation, etc., achieve good desulfurization and purification effect, reduce Adverse effects, effects of many active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

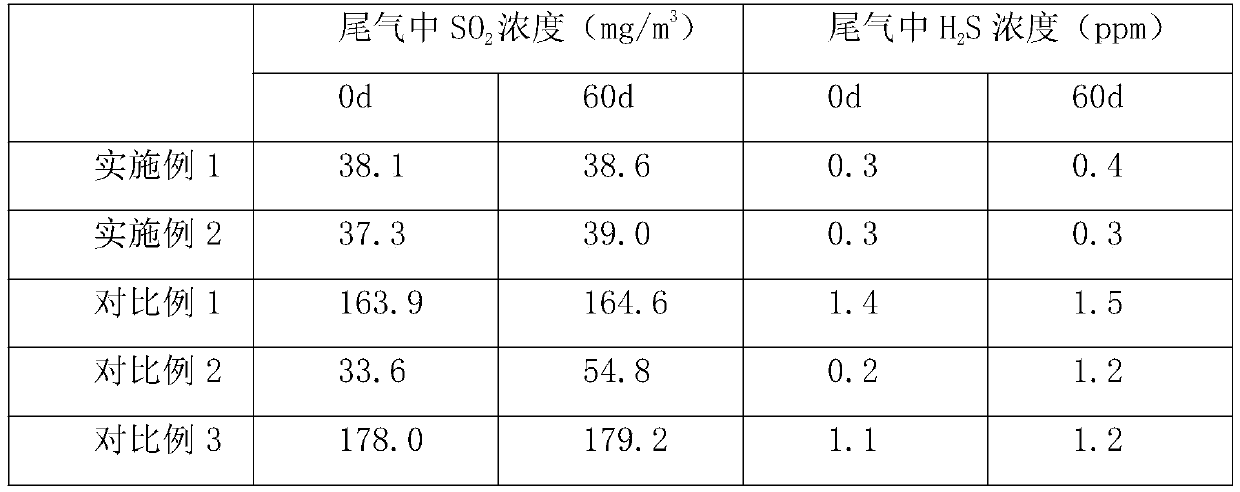

Examples

Embodiment 1

[0025] A method for cleaning and purifying sulfur-containing tail gas, comprising the following steps:

[0026] (1) The acidic sulfur-containing tail gas is passed into the combustion furnace for treatment at 1100 ° C. The treated gas is first passed into the waste heat boiler for waste heat recovery, and then passed into the first-level Claus reactor, the first-level Claus reactor The inlet temperature is 235°C. After the reaction is carried out in the first-stage Claus reactor, it is cooled to 150°C by the first-stage condenser, and then heated to 225°C by the heat exchanger, and then passed into the second-stage Claus reactor. After the reaction, it is cooled to 150°C by the secondary condenser to condense and separate the liquid sulfur to be collected through the liquid sulfur trap, and the Claus tail gas after the liquid sulfur is separated enters the next step of treatment;

[0027] (2) Send the Claus tail gas to the bottom of the spray tower to make the gas run upwards....

Embodiment 2

[0032] A method for cleaning and purifying sulfur-containing tail gas, comprising the following steps:

[0033](1) The acidic sulfur-containing tail gas is passed into the combustion furnace for treatment at 1300 ° C. The treated gas is first passed into the waste heat boiler for waste heat recovery, and then passed into the first-level Claus reactor, the first-level Claus reactor The inlet temperature is 245°C. After the reaction is carried out in the first-stage Claus reactor, it is cooled to 160°C by the first-stage condenser, and then heated to 235°C by the heat exchanger, and then passed into the second-stage Claus reactor. After the reaction, it is cooled to 160°C by the secondary condenser to condense and separate the liquid sulfur to be collected through the liquid sulfur trap, and the Claus tail gas after the separation of liquid sulfur enters the next step of treatment;

[0034] (2) Send the Claus tail gas to the bottom of the spray tower to make the gas run upwards....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com