Pressure sensor, electronic skin and touch screen equipment

A pressure sensor and equipment technology, applied in the field of electronic skin, touch screen equipment, security alarm system, and array pressure sensor, can solve the problems of increased system weight, increased burden and cost of the system, and achieve miniaturization and multi-function , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

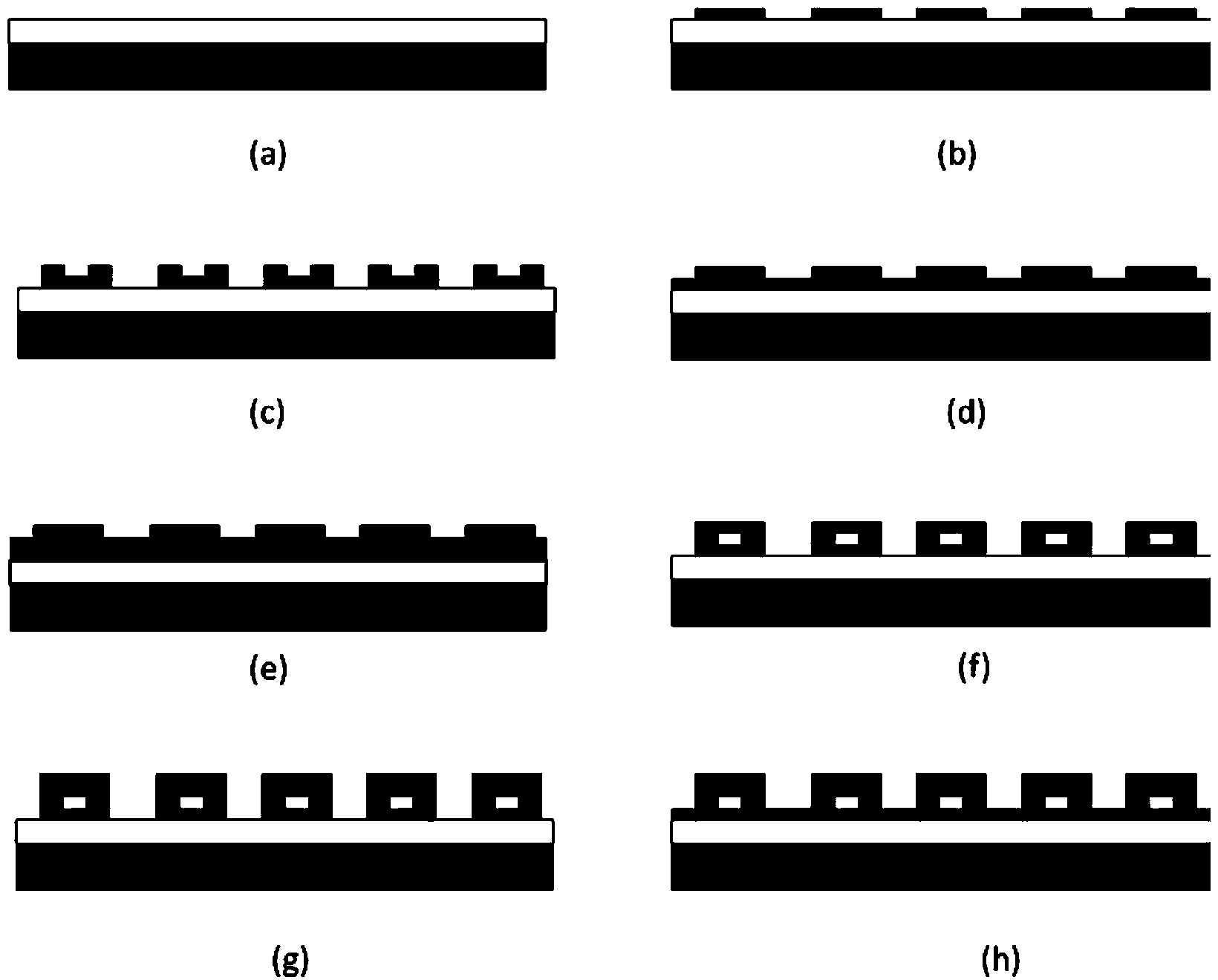

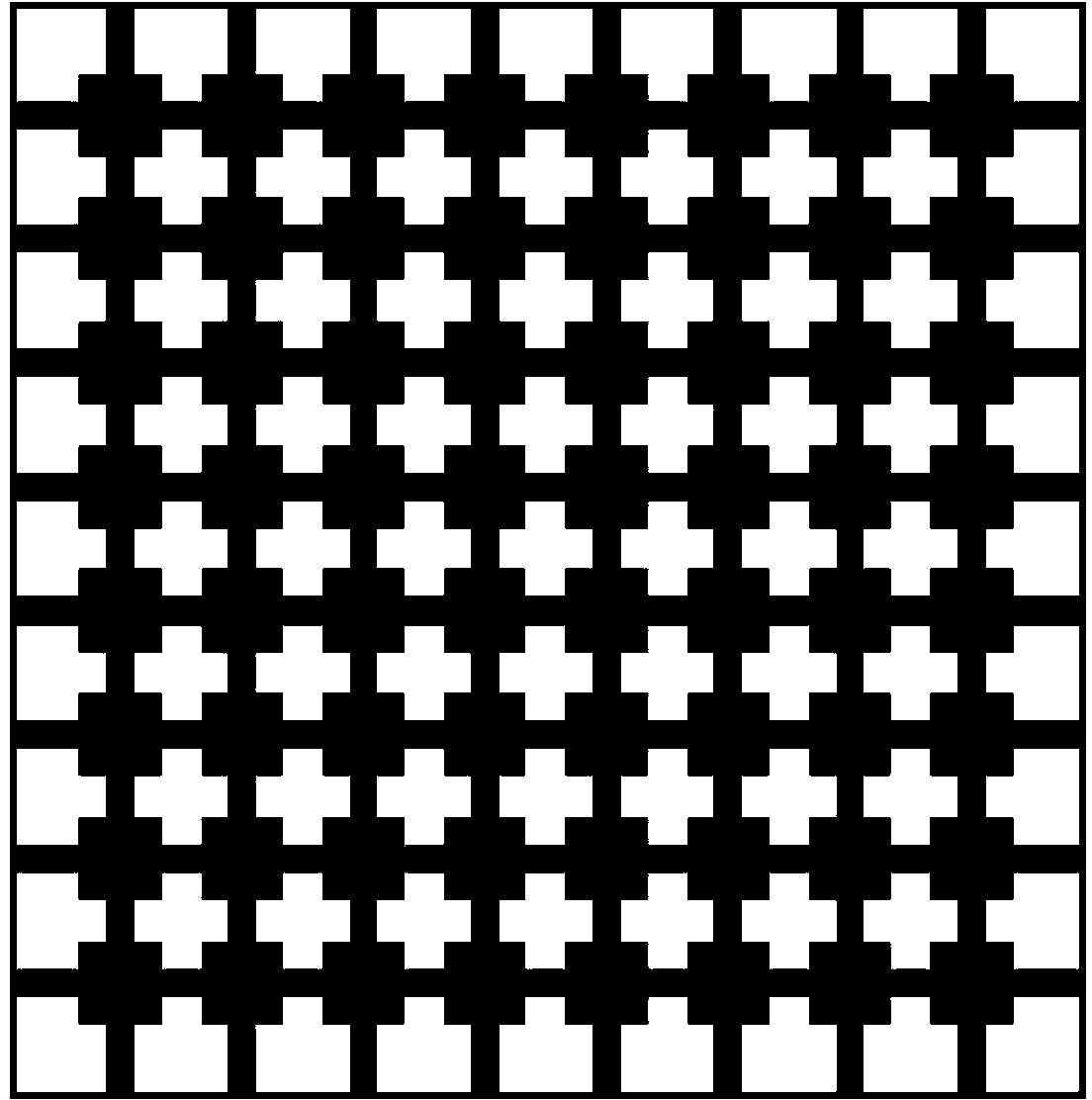

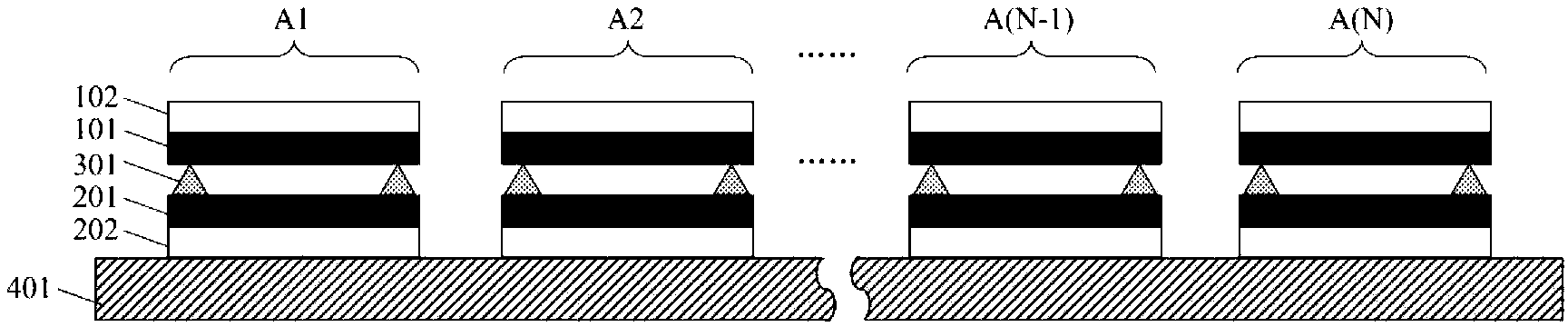

[0049] The typical structure of the self-driving pressure sensor provided by the present invention can be found in figure 1 and 2 , figure 1 A schematic diagram of the cross-sectional structure of the pressure sensor, figure 2 It is a schematic top view of a pressure sensor, and the pressure sensor includes: a substrate 401, and M×N sensor units A1, A2, . The array arrangement of columns ( figure 2 only schematically shows an array of 4 rows and 4 columns), wherein each sensing unit includes a first friction layer 101, a first electrode layer 102 arranged in contact with the upper surface of the first friction layer 101, a second friction layer 201 And the second electrode layer 202 (such as figure 1 shown), wherein the second electrode layer 202 and the substrate 401 are fixedly arranged, and the elastic connector 301 is provided in the sensing unit so that the lower surface of the first friction layer 101 and the upper surface of the second friction layer 201 are arran...

Embodiment 2

[0097] The present invention provides an electronic skin device, the electronic skin includes the pressure sensor described in Embodiment 1, wherein, in the pressure sensor, the first friction layer, the second friction layer, and the first electrode layer of each sensing unit Both the second electrode layer and the second electrode layer are made of flexible materials. For example, the active part of the sensing unit consists of polyparadimethylsiloxane (PDMS) film and aluminum foil. Because PDMS is a kind of polymer material with soft texture and good biocompatibility, sensor network devices made of PDMS can be well attached to the surface of muscle tissue of human body or robot, and the electrostatic nano power generation as the sensing unit When the machine is subjected to external force or extrusion, it can generate electrical signal output without additional power supply. Therefore, the electronic skin provided by the present invention is a self-driven artificial electro...

Embodiment 3

[0101] The present invention proposes a touch screen device, including the pressure sensor in Embodiment 1, wherein the first friction layer, the second friction layer, the first electrode layer, and the second electrode layer of each sensing unit in the pressure sensor are all Light-transmitting materials are used. For example, polyethylene terephthalate (PET) film coated with indium tin oxide (ITO) and polyparadimethylsiloxane (PDMS) are used as the effective part of the sensing unit, that is, the first friction layer PET is used, PDMS is used for the second friction layer, and ITO is used for both the first electrode layer and the second electrode layer. Since these materials are all transparent, the touch screen device made of these materials will have good light transmission and will not affect the normal operation of the display below the touch screen.

[0102] The display device provided by the invention can be applied to the displays of electronic computers, mobile ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com