Methods of removing rust from a ferrous metal-containing surface

A technology of iron and composition, applied in chemical instruments and methods, non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, etc., can solve the problems of undesired chemical environment and safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

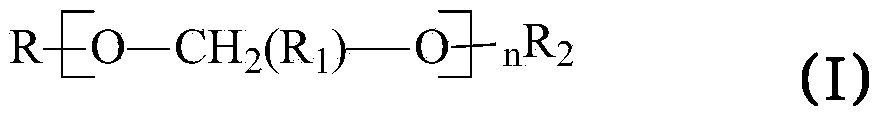

Method used

Image

Examples

Embodiment 1

[0036] Five solutions were prepared with the ingredients and amounts (in grams) listed in Table 1. The corroded plate was cleaned by using a commercially available alkaline cleaner (CK2010, commercially available from PPG Industries, Inc.) to clean a 3x4 inch bare cold-rolled steel plate (available from ACT Test Panels LLC273 Industrial, Dr. Hillsdale, MI49242), and then Place the plate in the salt spray chamber for 4 hours to prepare. The board was rinsed with deionized water and air dried under ambient conditions, and then the solution was applied.

[0037] Table 1

[0038] Ingredients

Example 1A

Example 1B

Example 1C

Example 1D

Example 1E

Laponite RD 1

6

--

--

--

--

Klucel M 2

--

1.5

--

--

--

Klucel H 3

--

--

1.5

--

--

--

--

--

15

--

Gelatin (calfskin) 5

--

--

--

--

15

Deionized water

114

118.5

118.5

105

105

30

30

30

30

30

[0039] 1 Laponite RD is commercially available from Southern Clay Products, Inc. In Example 1...

Embodiment 2

[0049] Three solutions were prepared with the ingredients and amounts (in grams) listed in Table 3. In each example, the clay was sprinkled into the water with stirring. The Laponite RD-containing material showed increased viscosity after several minutes of incorporation. Within 20 minutes, the solution became transparent and there were no visible particles. The bentonite solution showed a very slight viscosity change after adding water, and the material remained opaque blue-green. The kaolin material did not show any viscosity change after addition. After the various clays were added, the solution was stirred for about 20 minutes, citric acid was added, and the resulting mixture was stirred for about 10 minutes.

[0050] table 3

[0051] Ingredients

Example 2A

Example 2B

Example 2C

Deionized water

380

380

380

Laponite RD 1

20

--

--

--

20

--

Kaolin 2

--

--

20

100

100

100

[0052] 1 It is commercially available from Southern Clay Produ...

Embodiment 3

[0059] Three solutions containing the same theoretical amount of chloride ion were prepared using the ingredients and amounts (in grams) listed in Table 5. In each case, Laponite RD was added to the water according to the manufacturer's recommendations. Then the citric acid was slowly added while stirring the solution. For Example 3A, hydrochloric acid was then added dropwise with stirring. For Example 3B, sodium chloride was then added with stirring. For Example 3C, ammonium chloride was then added with stirring.

[0060] table 5

[0061] Ingredients

Example 3A

Example 3B

Example 3C

Deionized water

317.5

342.9

346.1

Laponite RD

20

20

20

100

100

100

37%HCl 1

62.5

--

--

NaCl 1

--

37.1

--

NH 4 Cl 1

--

--

33.9

[0062] 1 It is commercially available from VWR International, LLC.

[0063] The corroded plate was prepared as in Example 1. The three solutions were applied to a board placed at an angle of approximately 80° to the horizontal. After 1 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water solubility | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com