Bus bar for forming fuse block circuit, fuse link, and method of making fuse link

A technology of bus bars and fuses, which is applied in the manufacture of fuses, the manufacture of contact boxes/bases, circuits, etc., and can solve the problems of easy deformation and low strength of fusible parts 113

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

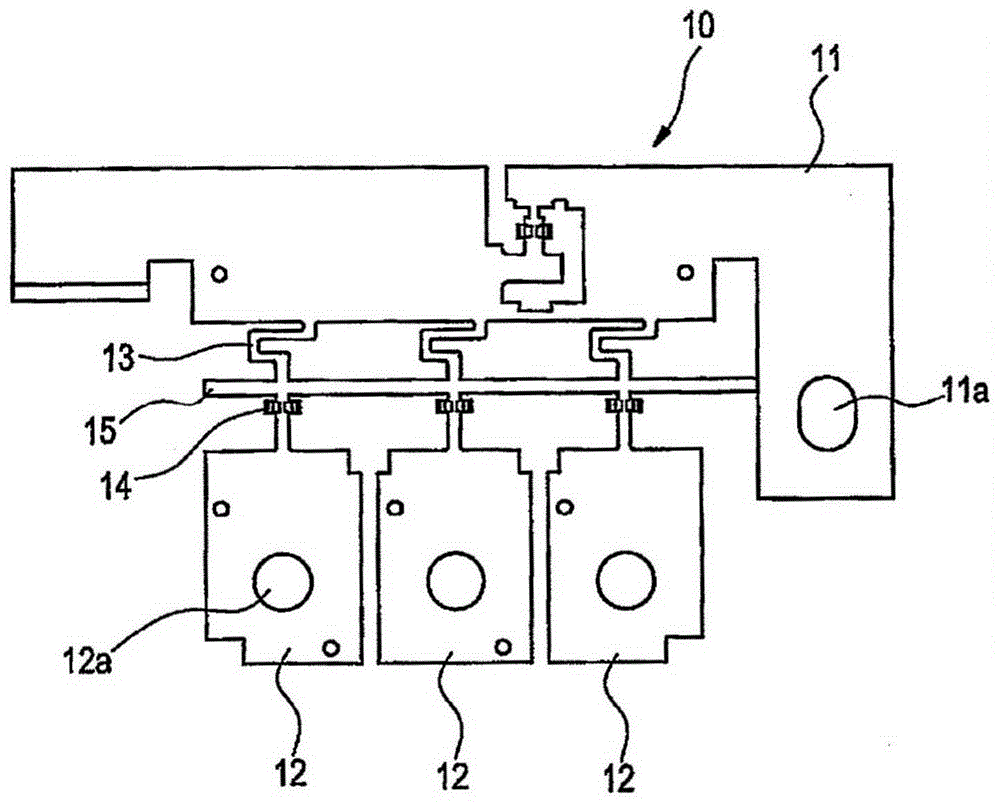

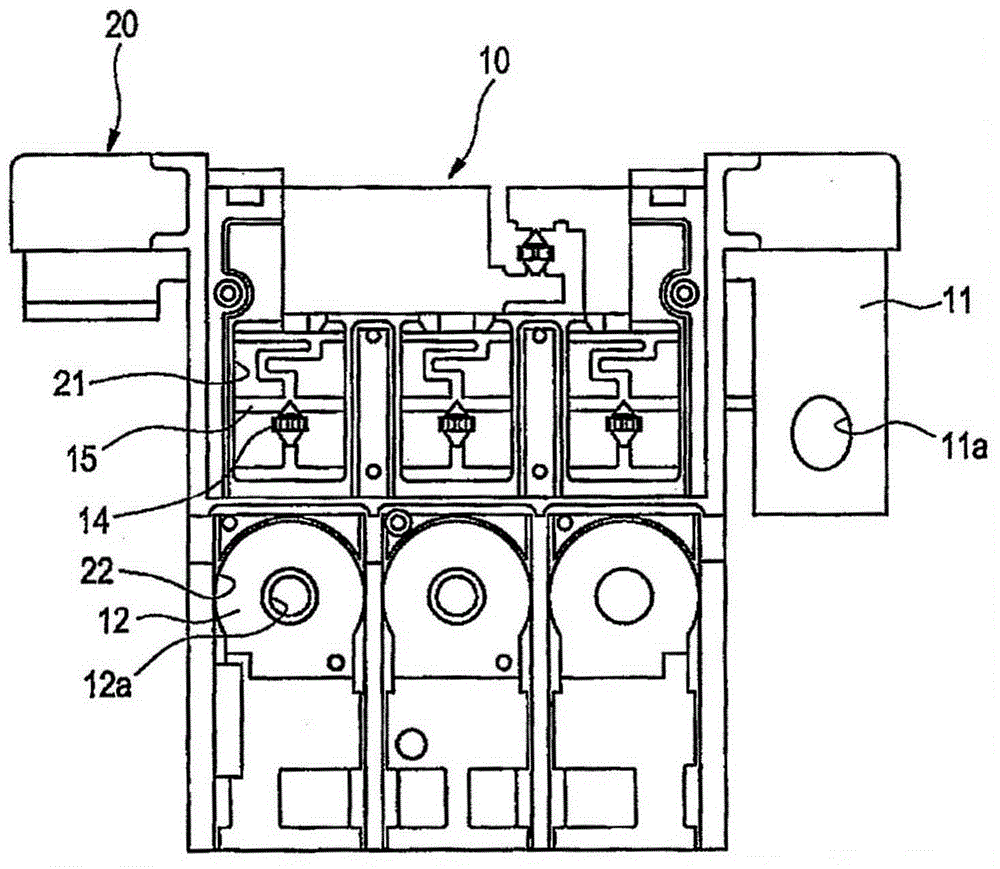

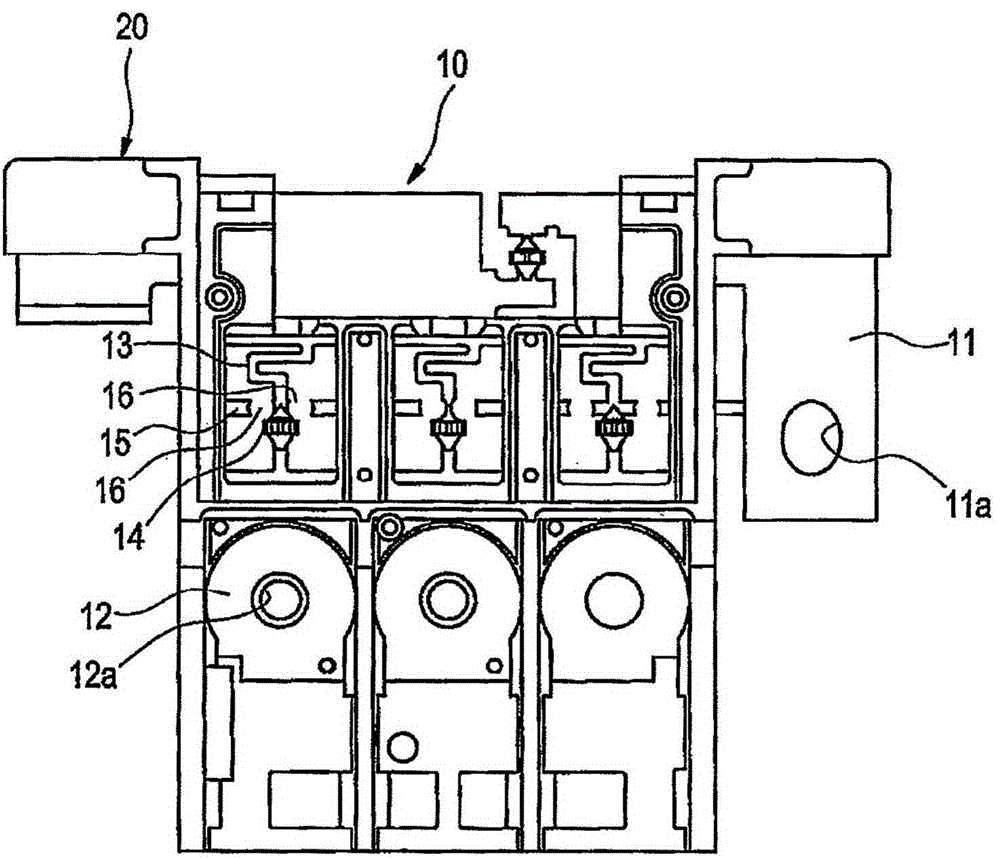

[0047] Embodiments of the present invention will be described below with reference to the accompanying drawings.

[0048] Such as Figures 1 to 3 As shown, the fuse block according to the present embodiment includes: a bus bar (circuit forming bus bar) 10 for forming a circuit, the bus bar 10 is manufactured by press-working a metal plate; and a resin case 20, the resin case 20 After the bus bar 10 is set in the mold, the bus bar 10 is insert-molded so as to partially cover the outer periphery of the bus bar 10 or the like.

[0049] Such as figure 1 As shown, the bus bar 10 includes: a power supply side terminal board 11 to be connected to the battery; and a plurality of load side terminal boards 12 via respective fusible parts 13 (a portion through which the current flows is reduced in cross-sectional area and thus easily fused due to Joule heat) is connected to the power supply side terminal board 11 so as to form a branch circuit from the power supply side terminal board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com