System for continuously producing aluminum products and continuous production method

A production system and technology of aluminum products, applied in the field of continuous production system of aluminum products, can solve the problems of impracticality, adjustment of aluminum alloy composition, difficulty in quenching and tempering, etc., and achieve the reduction of intermediate inventory, shorten the lead time, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

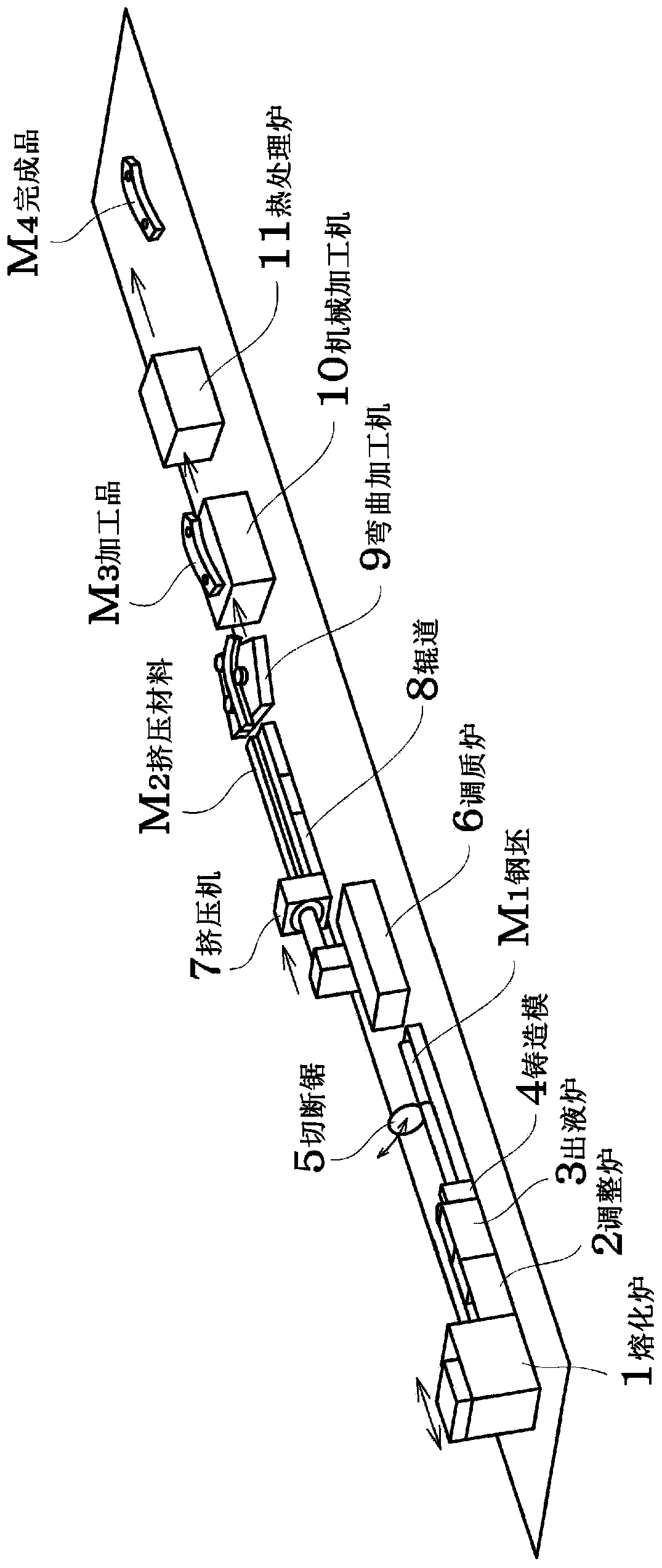

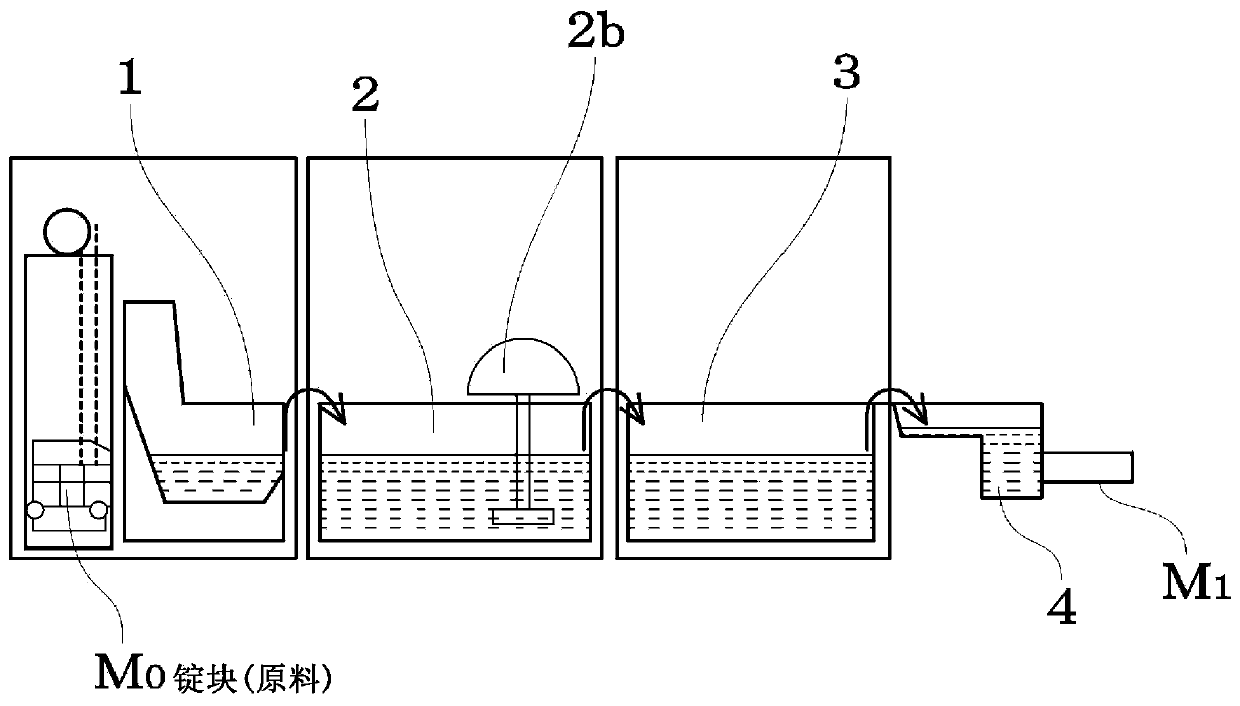

[0038] based on figure 1 A configuration example of the continuous production system according to the present invention will be described.

[0039] The casting process of the aluminum alloy billet is as follows.

[0040] There is a melting furnace 1: a raw material (ingot) for melting aluminum.

[0041] Equipped with adjustment furnace 2: necessary alloy components such as Mg, Si, Zn and Cu need to be adjusted in the molten aluminum, and the master alloy is put into the molten aluminum for adjustment.

[0042] Next, there is a liquid outlet furnace 3 : continuously inject the molten liquid whose composition has been adjusted into the casting mold 4 .

[0043] exist figure 2 These series of structures are schematically shown in .

[0044] The ingot (raw material) M is charged into the melting furnace 1 using a feeding machine such as a chain device 0 , for heating and melting.

[0045] The melt of this raw material is moved into the adjustment furnace 2, and the alloy co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com