Printed circuit board

A technology of printed circuit substrates and substrates, applied in the direction of printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of long process and large environmental load, and achieve the effects of reducing intermediate inventory, being environmentally friendly, and shortening the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

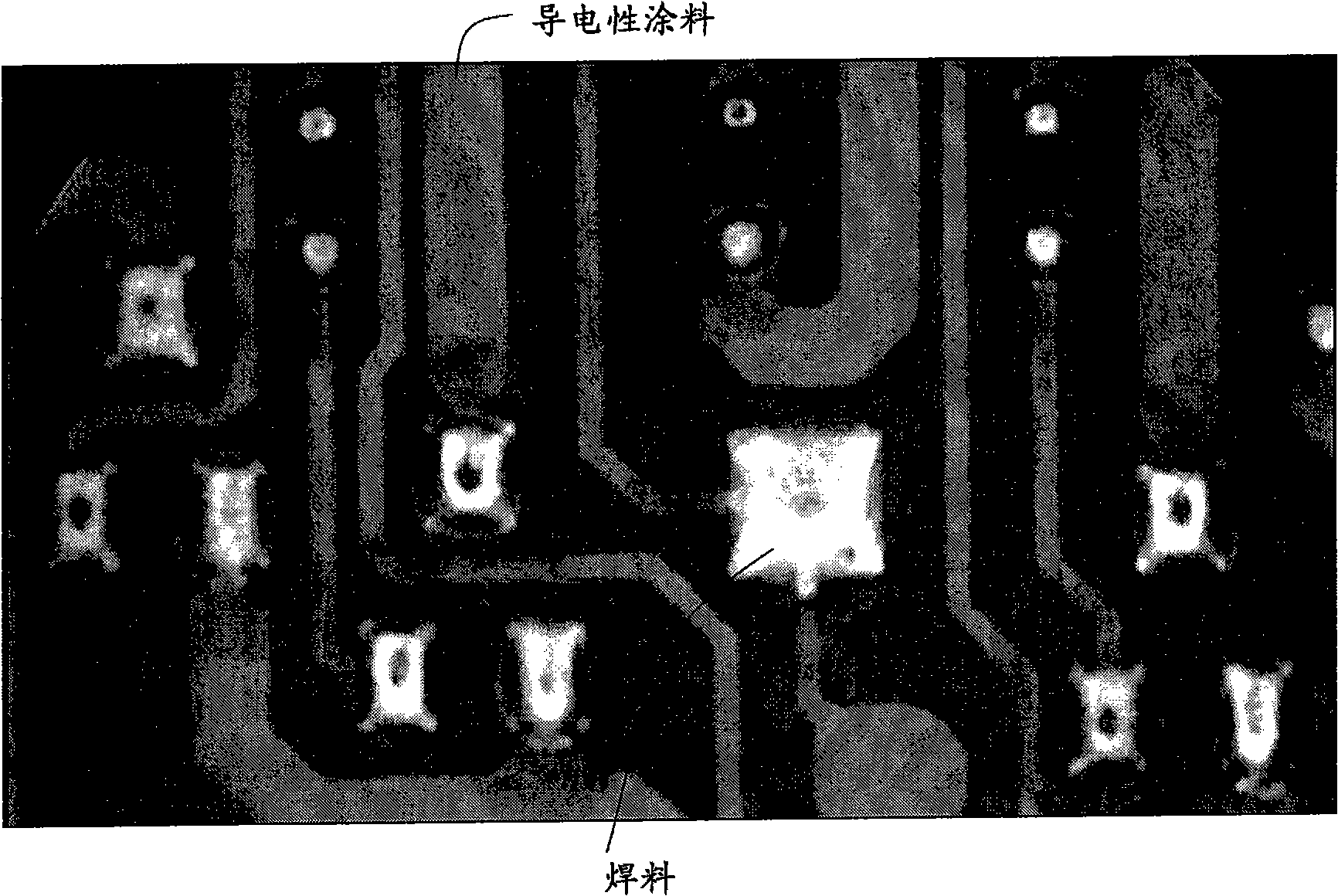

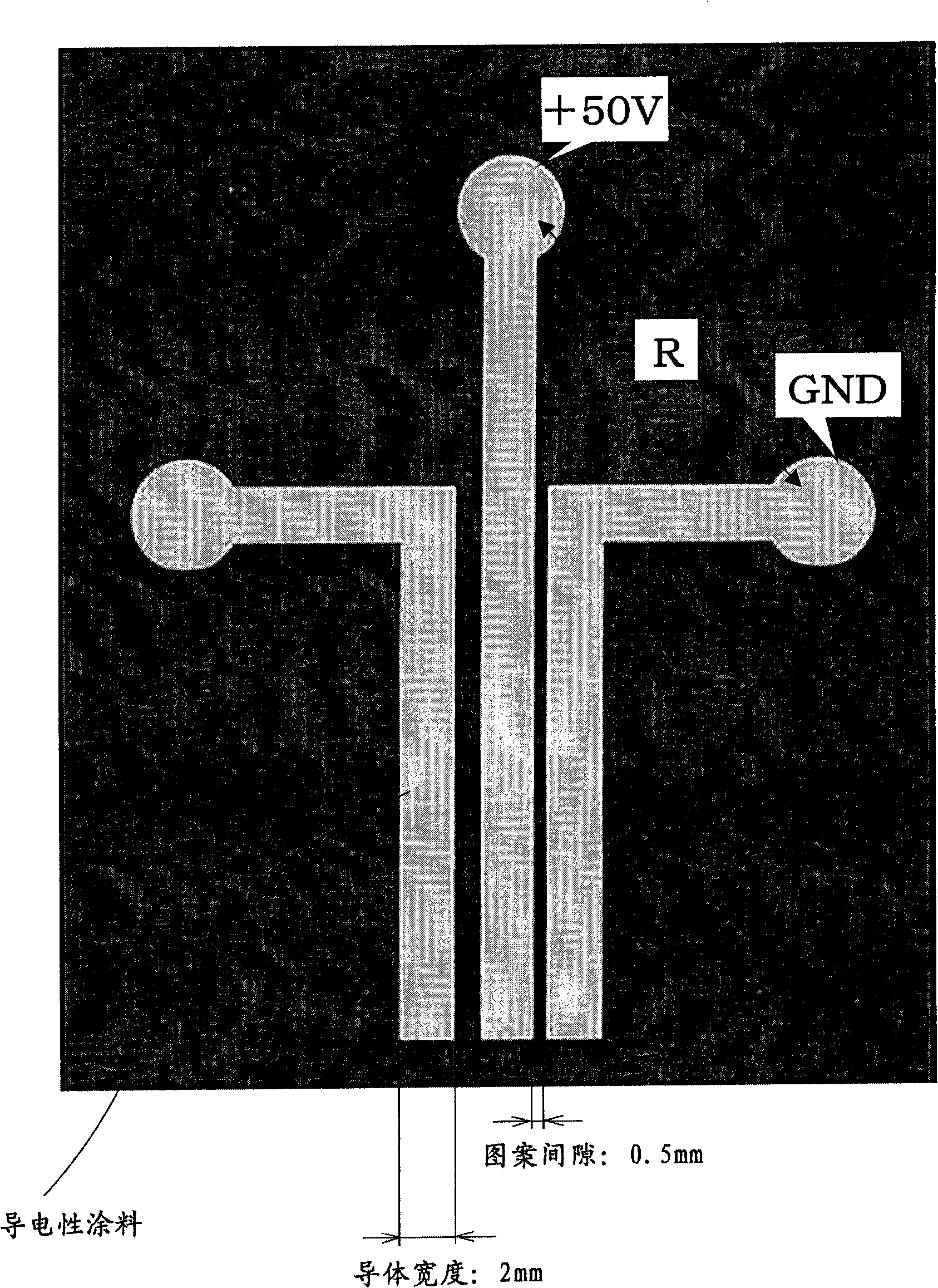

[0024] The printed circuit board according to the present invention is applicable to various electronic boards, but in this example, the case where it is used as a remote control board for remote operation of electric and electronic equipment is evaluated as an example, and will be described below.

[0025] As a phenolic paper substrate material for impregnating a paper substrate with a phenolic resin, the following two types were prepared: substrate material A (manufactured by Richang Industry Co., Ltd., PS-1131) with a thickness of 1.6 mm and an absorption rate of 2.0%; 0.8% of substrate material B (manufactured by Risho Kogyo Co., Ltd., PS-1143S).

[0026] As substrate materials for resin-impregnated paper substrates, in addition to phenolic paper substrate materials, epoxy paper substrate materials impregnated with epoxy resin are also readily available, but phenolic paper substrate materials are usually cheaper.

[0027] In a word, in the present invention, there is no ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com