Method for preparing cold-soluble green tea powder and product

A green tea powder, cold-dissolving technology, applied in the direction of tea, tea extraction, food science, etc., can solve the problems of poor taste, color and luster, poor cold-solubility, etc., and achieve the effect of increasing green retention, green color and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

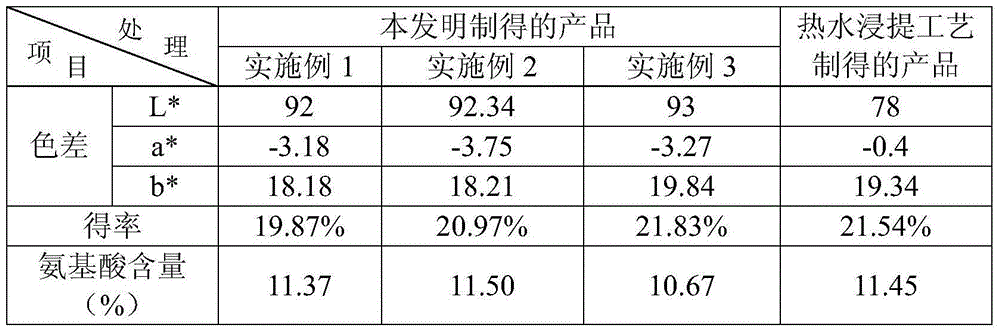

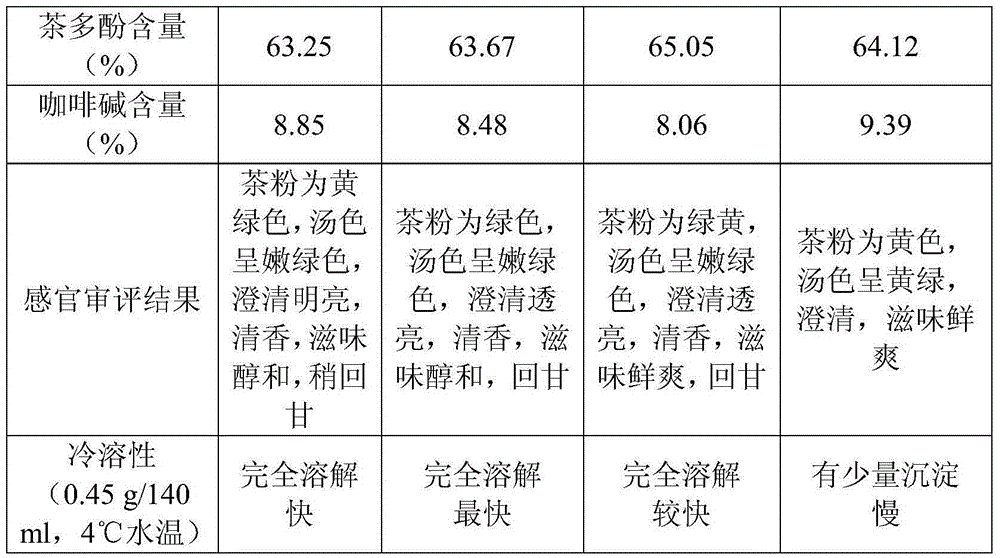

Embodiment 1

[0021] The method for preparing cold-melt green tea powder comprises the steps:

[0022] A. Select 1kg of high-quality green tea, grind it with a grinder, add 30kg of deionized water after passing through a 40-mesh sieve, seal it, and then extract it for 30min under a pressure of 100Mpa to obtain an extract;

[0023] B. Pass the extract obtained in step A through a 150-mesh filter cloth, collect the filtrate, and centrifuge the filtrate for 30 minutes at a rotating speed of 3500r / min, collect the supernatant, and obtain tea soup;

[0024] C. Concentrating the tea soup obtained in step B by reverse osmosis until the soluble solids reach 16%, to obtain a concentrated solution;

[0025] D. Put the concentrated solution obtained in step C into the refrigerator to freeze and freeze, and after freezing, vacuum freeze-dry at -40°C for 48 hours to obtain cold-soluble green tea powder.

[0026] The cold-melt green tea powder prepared in this example is 197g. Take 0.45g into a cup and ...

Embodiment 2

[0028] The method for preparing cold-melt green tea powder comprises the steps:

[0029] A. Select 1 kg of high-quality green tea, grind it with a grinder, add 20 kg of deionized water after passing through an 80-mesh sieve, seal it, and then extract it for 20 minutes under a pressure of 200 MPa to obtain an extract;

[0030] B. Pass the extract obtained in step A through a 200-mesh filter cloth, collect the filtrate, and centrifuge the filtrate for 30 minutes at a rotating speed of 4000r / min, collect the supernatant, and obtain tea soup;

[0031] C. using reverse osmosis to concentrate the tea soup gained in step B until the soluble solids reach 20%, to obtain a concentrated solution;

[0032] D. Put the concentrated solution obtained in step C into the refrigerator to freeze and freeze, and after freezing, vacuum freeze-dry at -50°C for 36 hours to obtain cold soluble green tea powder.

[0033] The cold-melt green tea powder prepared in this example is 205g. Take 0.45g into...

Embodiment 3

[0035] The method for preparing cold-melt green tea powder comprises the steps:

[0036] A. Select 1 kg of high-quality green tea, grind it with a grinder, add 15 kg of deionized water after passing through a 60-mesh sieve, seal it, and extract it for 10 minutes under a pressure of 300 MPa to obtain an extract;

[0037] B. Pass the leaching solution obtained in step A through a 300-mesh filter cloth, collect the filtrate, and centrifuge the filtrate for 30 minutes at a rotating speed of 5500r / min, collect the supernatant, and obtain tea soup;

[0038] C. Concentrating the tea soup obtained in step B by reverse osmosis until the soluble solids reach 22%, to obtain a concentrated solution;

[0039] D. Put the concentrated solution obtained in step C into the refrigerator to freeze and freeze, and after freezing, vacuum freeze-dry at -50°C for 36 hours to obtain cold soluble green tea powder.

[0040] The cold-melt green tea powder prepared in this example is 205g. Take 0.45g in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com