Preparation method of high-tea-polyphenol high-caffeine cold-soluble tea powder

A technology for caffeine and tea polyphenols is applied in the field of preparation technology of cold-soluble tea powder, which can solve the problems of low yield and the like, and achieve the effects of good cold-solubility, low equipment requirements and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

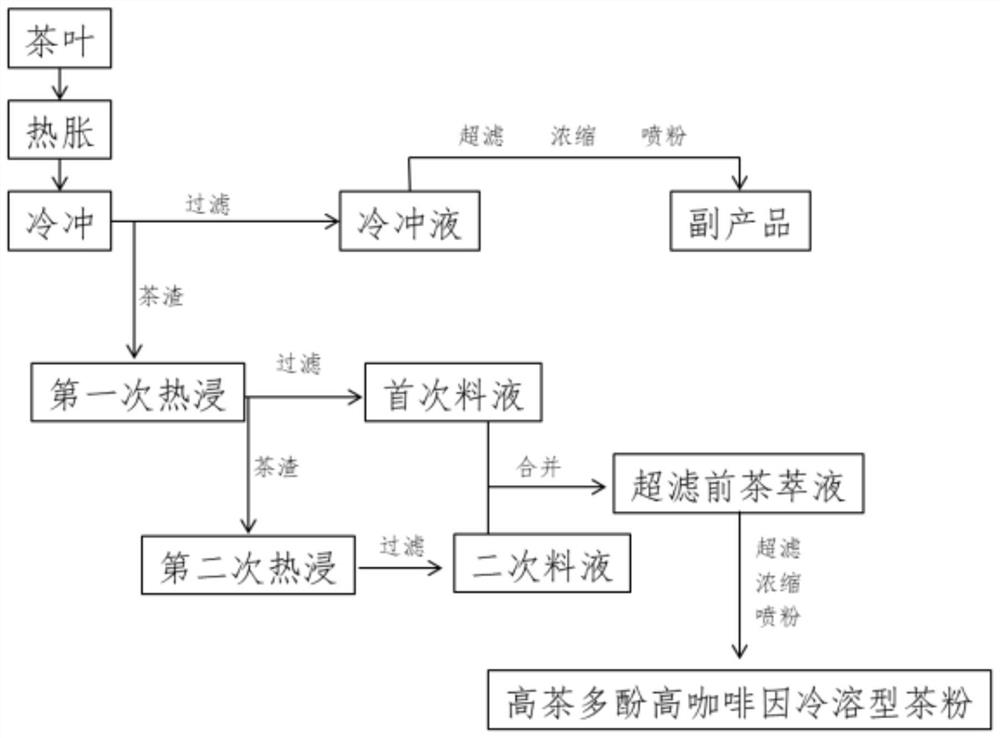

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, a kind of preparation method of high tea polyphenol and high caffeine cold soluble type tea powder, carry out the following steps successively:

[0044] ①, tea thermal expansion:

[0045] Soak 10kg of tea samples in 10kg of boiling water and stir for 15min to make the tea leaves fully absorb water, that is, make the tea leaves fully thermally swell;

[0046] That is, the solid-liquid ratio is 1:1;

[0047] ②, cold punch:

[0048] In step 1. in the gained, add the cold water of 80kg, after evenly stirring (stirring time is about 3 minutes), filter, respectively obtain tea residue and filtrate (as by-product);

[0049] Described (cold water+the boiling water of step ①): the weight ratio of tea leaves=9:1;

[0050] That is, in this step ②, the solid-liquid ratio of step ① is supplemented from 1:1 to 1:9 with cold water;

[0051] ③, leaching

[0052] In step 2. the obtained tea residue, add hot water 80kg and extract at 95 ℃, and the extraction time is 30...

Embodiment 2

[0062] Embodiment 2, with respect to embodiment 1, make the following changes:

[0063] Step ①: Thermal expansion of tea leaves:

[0064] Soak 10kg of tea samples in 15kg of boiling water and stir for 8min.

[0065] That is, the solid-liquid ratio is 1:1.5;

[0066] Step 2.: add the cold water of 100kg in step 1. in the gains, after uniform stirring, filter, respectively obtain tea residue and the filtrate as by-product;

[0067] Described (cold water+the boiling water of step 1): tea leaves=(10+1.5): the weight ratio of 1;

[0068] That is, in this step ②, the solid-liquid ratio of step ① is supplemented from 1:1.5 to 1:11.5 with cold water;

[0069] Step 3. The ratio of material to liquid during leaching is 1:9, the leaching temperature is 90°C, and the leaching time is 20min;

[0070] Step ⑤, using reverse osmosis for RO membrane concentration to Brix 13.8%.

[0071] The rest are identical to Example 1.

[0072] So in the end:

[0073] Step 6. Obtain 2077.5g of high te...

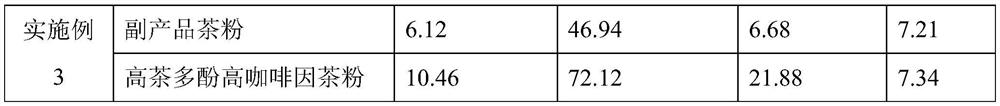

Embodiment 3

[0075] Embodiment 3, a kind of preparation method of high tea polyphenol and high caffeine cold-dissolving type tea powder, carry out the following steps successively:

[0076] ①, tea thermal expansion:

[0077] Soak 20kg of tea samples in 40kg of boiling water and stir for 10min to make the tea leaves fully absorb water, that is, make the tea leaves fully thermally swell;

[0078] That is, the solid-liquid ratio is 1:2;

[0079] ②, cold punch:

[0080] In step 1) in the gained, add the cold water of 200kg, after uniform stirring, filter, respectively obtain tea residue and the filtrate as by-product;

[0081] Described (cold water+the boiling water of step ①): the weight ratio of tea leaves=12:1;

[0082] That is, in this step ②, the solid-liquid ratio of step ① is supplemented from 1:2 to 1:12 with cold water;

[0083] ③, leaching:

[0084] Add 200kg of hot water to the tea residue obtained in step 2. to extract at 100°C, and the extraction time is 40min, that is, hot w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com