Correcting bracket

A bracket and archwire slot technology, applied in the field of orthodontics, can solve the problems of high manufacturing difficulty, difficult operation, complicated structure, etc., and achieve the effects of simple production, no tedious operation, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

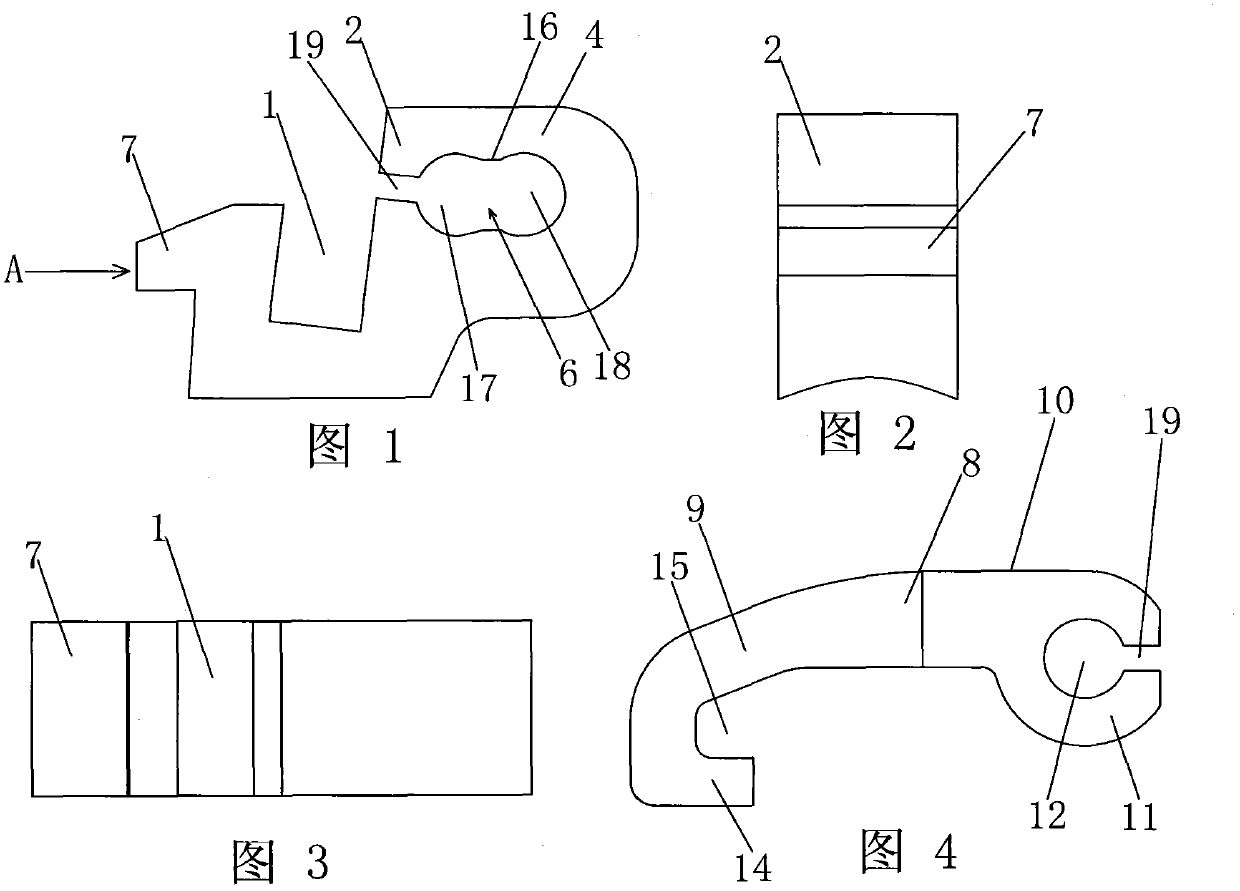

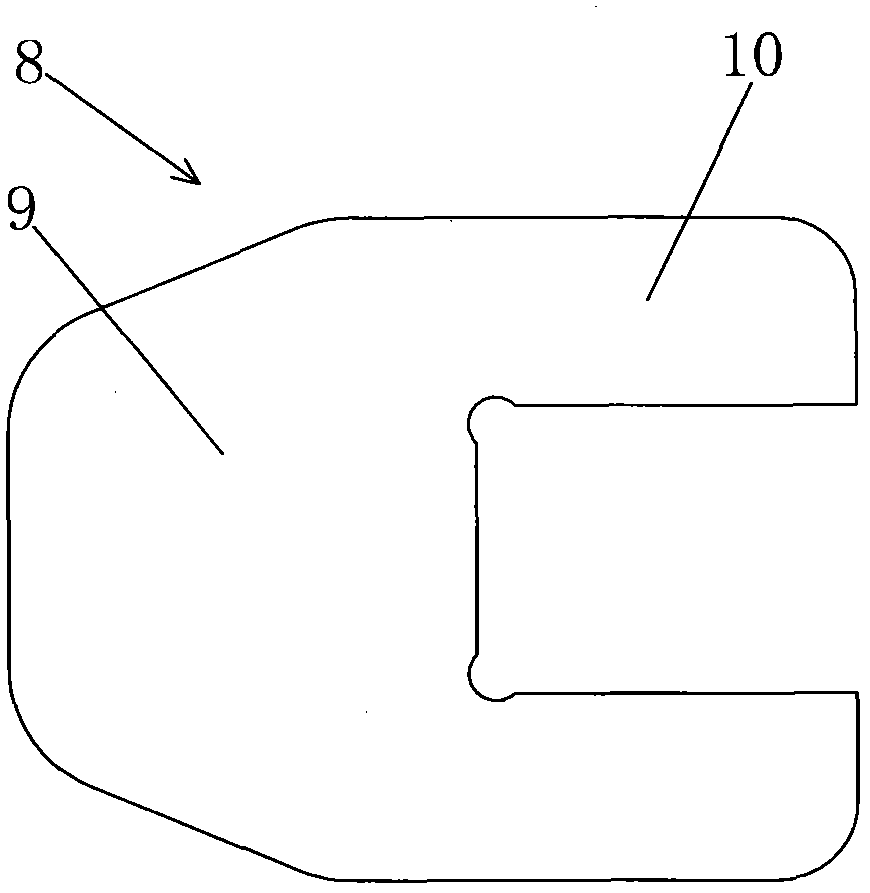

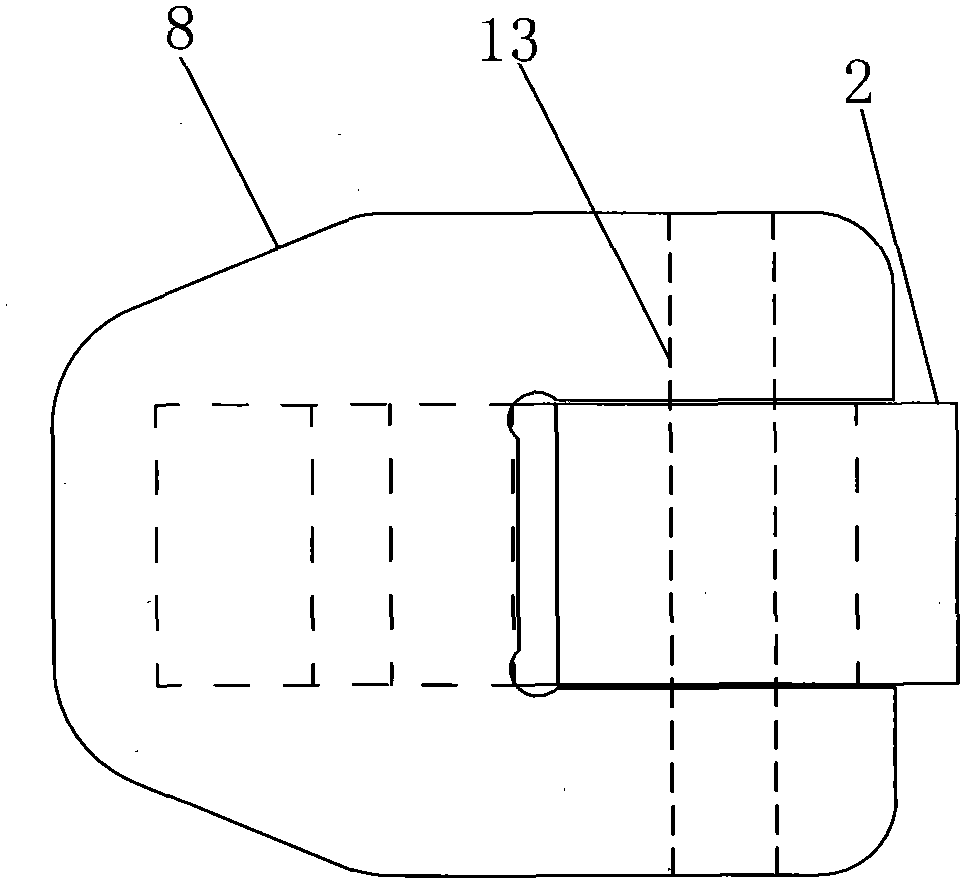

[0026] Embodiment: a kind of orthodontic bracket, as Figure 1~3 As shown, it includes a bracket body 2 with an archwire groove 1 and a bracket cover 8 matching with the bracket body 2. The right side of the archwire groove 1 is provided with a working wing 4. On the right side of the archwire groove 1 The working wing 4 is provided with a wire-cut waist hole 6, which can also be formed by EDM. The bracket body on the left side of the archwire groove 1 extends horizontally in a direction away from the archwire groove 1. There is a boss 7; such as Figure 4~6 As shown, the bracket cover 8 is U-shaped as a whole, and the bracket cover 8 is composed of a horizontal side 9 and a vertical side 10 extending from the two ends of the horizontal side 9 to the side of the horizontal side. A flange 11 is provided on the flange 11, and a shaft hole 12 formed by wire cutting is provided on the flange 11. Similarly, the shaft hole 12 can also be formed by electric discharge machining, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com