Cleaning liquid composition and reverse osmosis membrane cleaning method

A reverse osmosis membrane and cleaning solution technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve problems such as difficult to achieve cleaning effect, limited cleaning effect, etc., to reduce electrical conductivity, reduce pressure difference between front and back , The effect of water production recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is used to illustrate the method for cleaning the reverse osmosis membrane provided by the present invention.

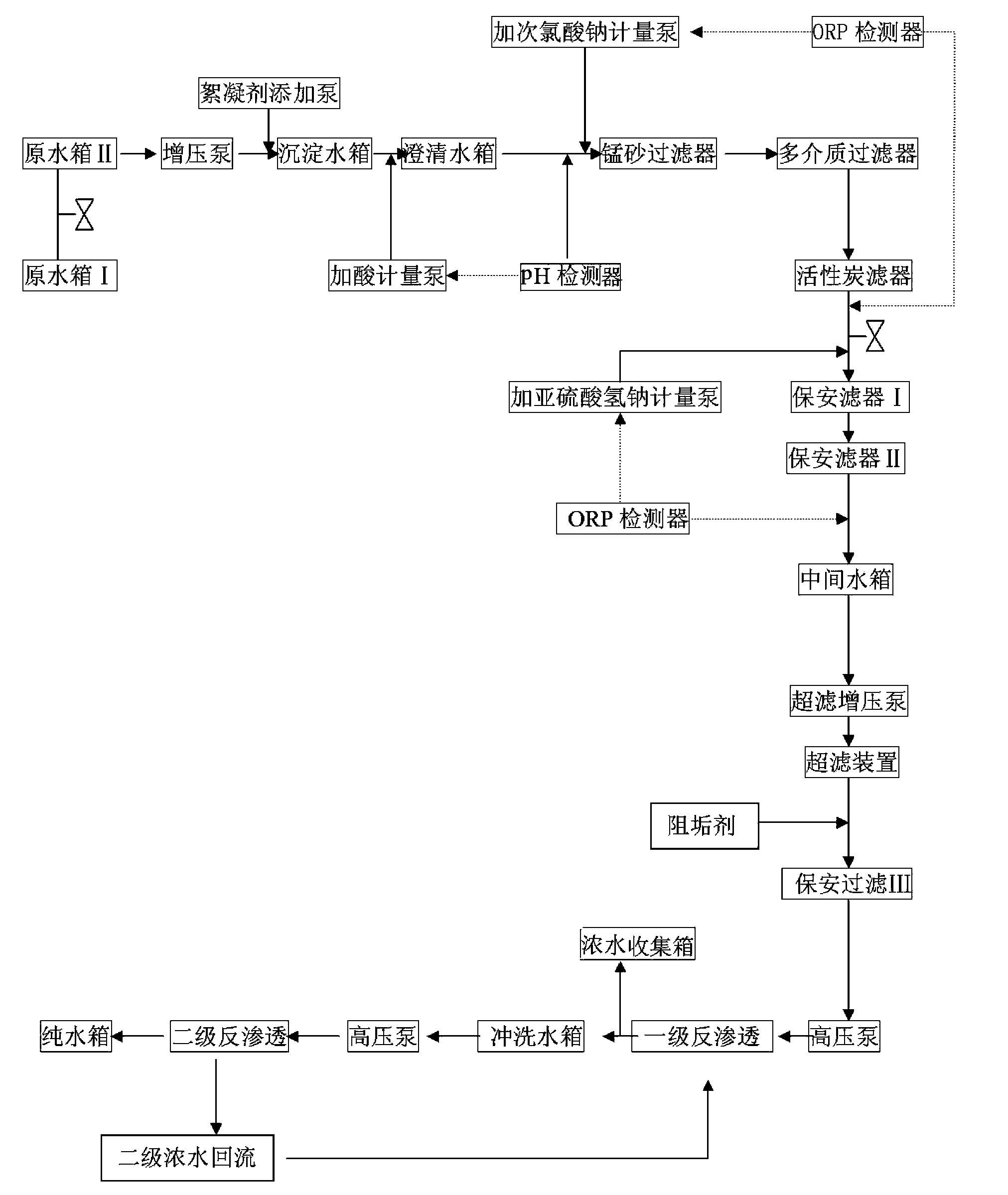

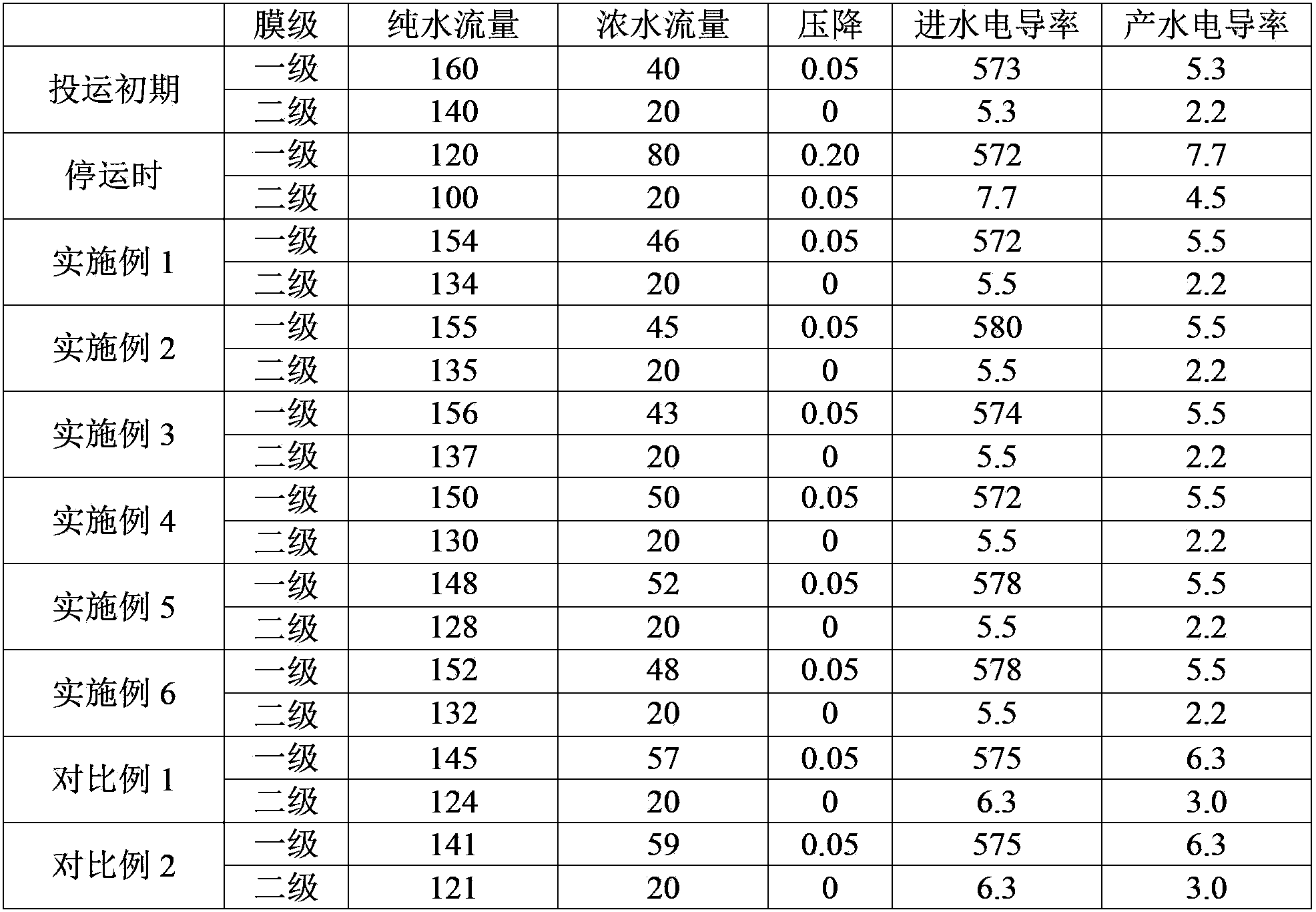

[0042] according to figure 1 In the process shown, the two-stage reverse osmosis system is used to treat the raw water with water quality parameters as shown in Table 1. The water treatment capacity is 200L / h until the pressure difference between the front and back of the first-stage reverse osmosis membrane increases by 15% or the pure water output Stop at 15% reduction. Then, clean the reverse osmosis membrane in the secondary reverse osmosis system according to the following process:

[0043] (1) Close the secondary reverse osmosis membrane, adjust the pressure of the primary reverse osmosis membrane to 0.4MPa, and rinse the primary reverse osmosis membrane with reverse osmosis product water at a temperature of 40°C for 10 minutes;

[0044] (2) Mix 20g of hydrazine hydrate with 100L of deionized water to obtain a cleaning solution; add the cleani...

Embodiment 2

[0053] This embodiment is used to illustrate the method for cleaning the reverse osmosis membrane provided by the present invention.

[0054] according to figure 1 In the process shown, the two-stage reverse osmosis system is used to treat the raw water with water quality parameters as shown in Table 1. The water treatment capacity is 200L / h until the pressure difference between the front and back of the first-stage reverse osmosis membrane increases by 15% or the pure water output Stop at 15% reduction. Then, clean the reverse osmosis membrane in the secondary reverse osmosis system according to the following process:

[0055] (1) Close the secondary reverse osmosis membrane, adjust the pressure of the primary reverse osmosis membrane to 0.1MPa, and rinse the primary reverse osmosis membrane with reverse osmosis product water at a temperature of 25°C for 40 minutes;

[0056] (2) Mix 100g of hydrazine hydrate with 100L of deionized water to obtain a cleaning solution; add the clean...

Embodiment 3

[0062] This embodiment is used to illustrate the method for cleaning the reverse osmosis membrane provided by the present invention.

[0063] according to figure 1 In the process shown, the two-stage reverse osmosis system is used to treat the raw water with water quality parameters as shown in Table 1. The water treatment capacity is 200L / h until the pressure difference between the front and back of the first-stage reverse osmosis membrane increases by 15% or the pure water output Stop at 15% reduction. Then, clean the reverse osmosis membrane in the secondary reverse osmosis system according to the following process:

[0064] (1) Close the secondary reverse osmosis membrane, adjust the pressure of the primary reverse osmosis membrane to 0.3MPa, and rinse the primary reverse osmosis membrane with reverse osmosis product water at a temperature of 35°C for 25 minutes;

[0065] (2) Mix 80g of hydrazine hydrate and 100L of deionized water uniformly to obtain a cleaning solution; add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com