Double-side grooving machine

A slotting machine, double-sided technology, applied in the field of sheet metal processing, can solve the problems of high technical requirements of workers, affecting product flatness, low production efficiency, etc., and achieve the effects of low technical requirements of workers, standardized production, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and examples.

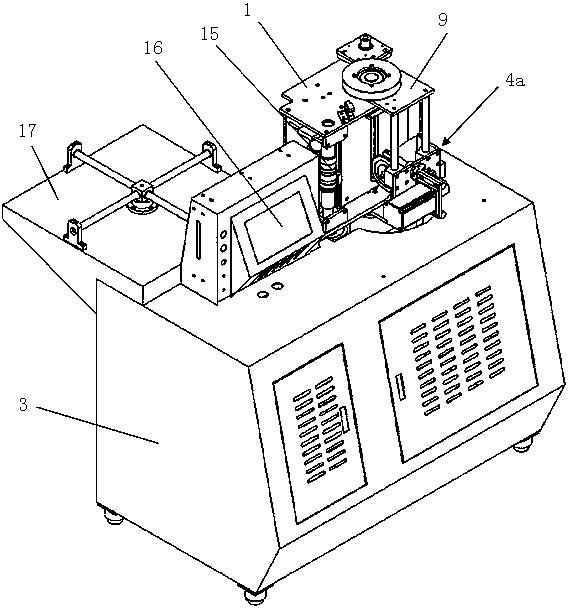

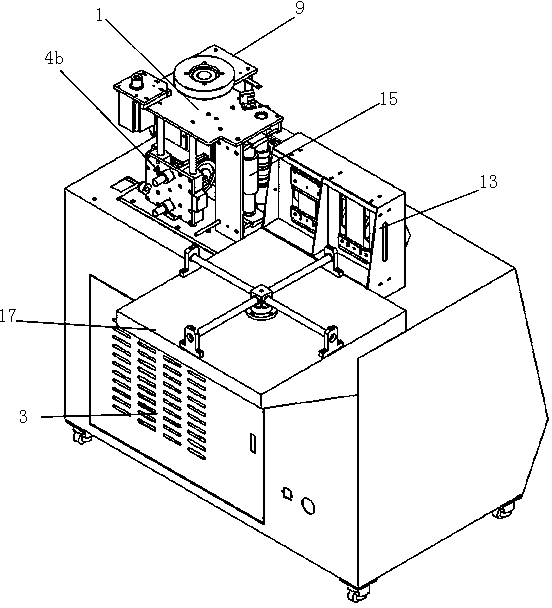

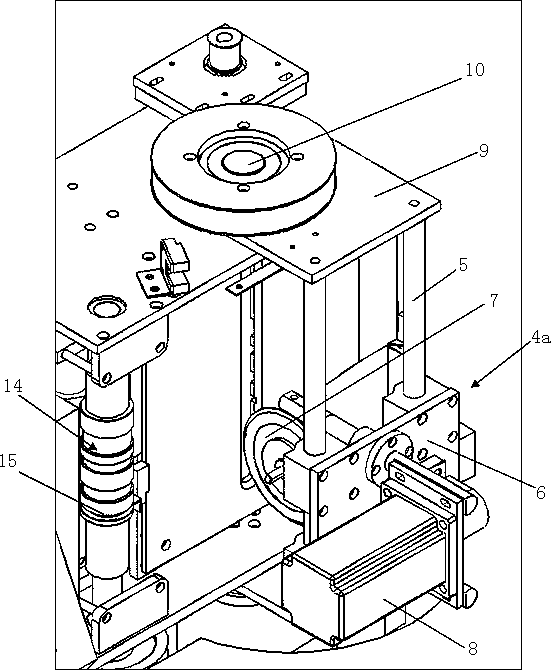

[0024] figure 1 It is a schematic diagram of the external structure of the double-sided slotting machine of the present invention; figure 2 It is a structural schematic diagram of the back of the double-sided slotting machine of the present invention; image 3 It is a partially enlarged view of the front grooving mechanism in the double-sided grooving machine of the present invention; Figure 4 It is a partial enlarged view of the slotting mechanism in the direction of sheet material conveying in the double-sided slotting machine of the present invention; Figure 5 It is a partially enlarged view of the reverse side grooving mechanism in the double-sided grooving machine of the present invention.

[0025] Such as Figure 1 to Figure 5 As shown, the two ends of the double-sided grooving machine of the present invention are respectively set as the feed end and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com