Numerical control machine tool cutting force load simulation device and method

A technology of CNC machine tools and loading devices, which is applied in the direction of metal processing equipment, metal processing machinery parts, measuring/indicating equipment, etc., which can solve the problems of not meeting the processing requirements, reducing the processing accuracy, and not being able to truly reflect the cutting process of the machine tool, etc. , to achieve the effect of improving the machining accuracy of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

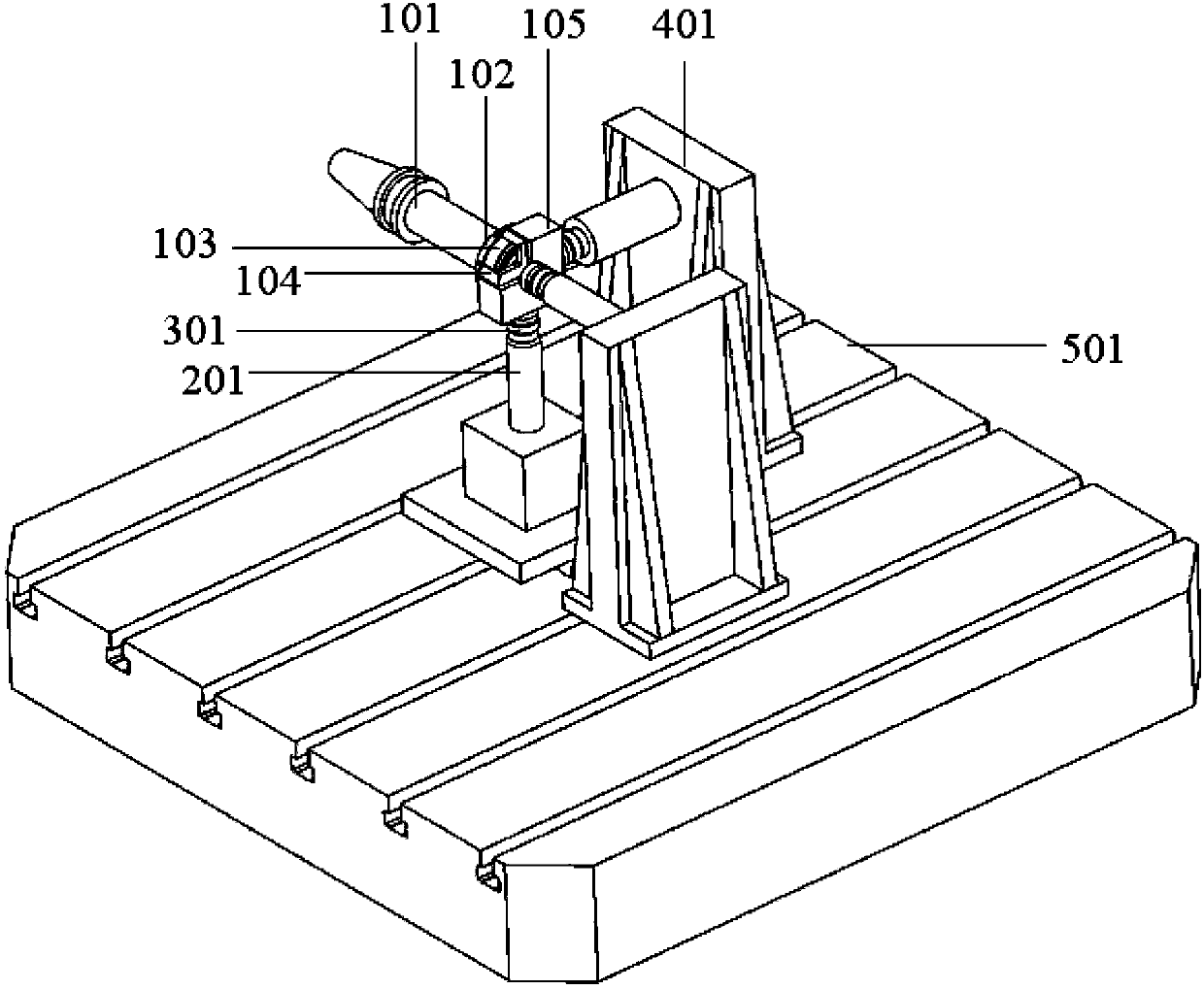

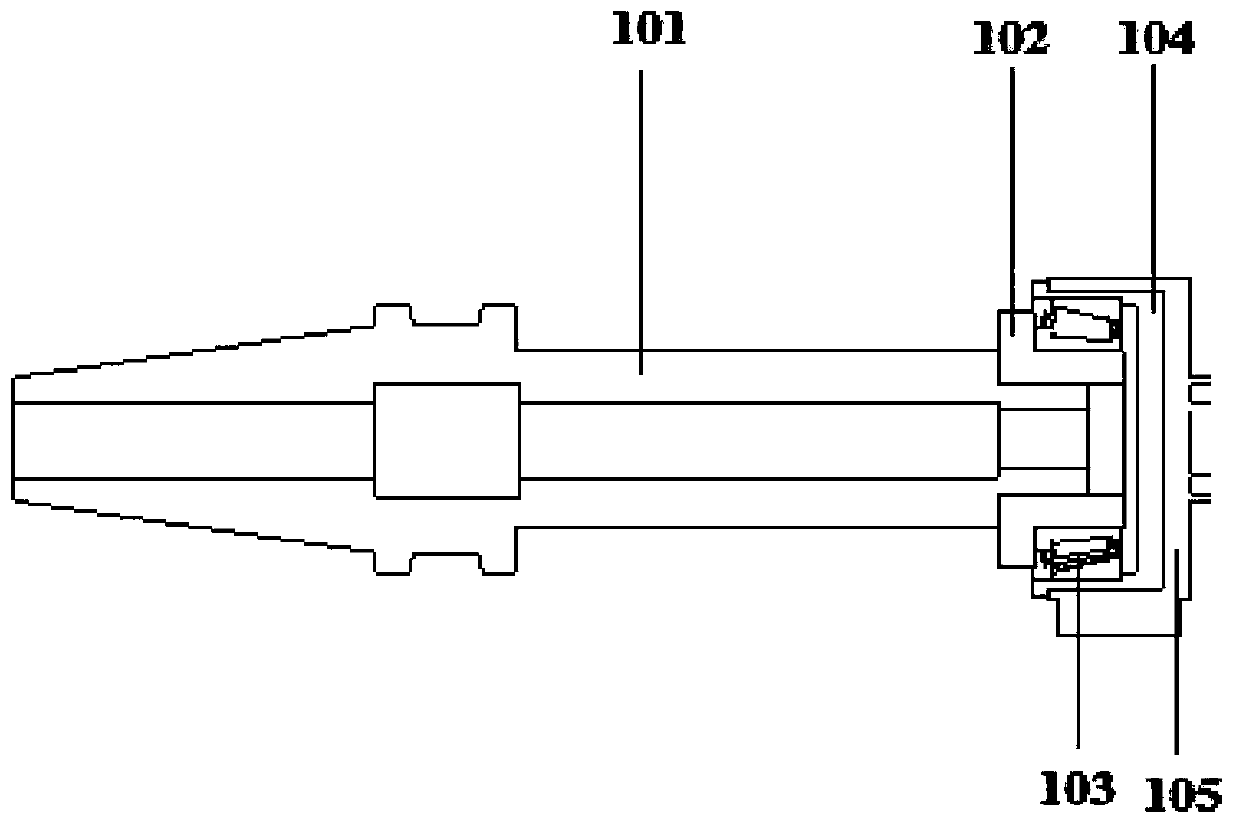

[0033] see figure 1 and figure 2 , the numerically controlled machine tool cutting force simulation loading device of the present invention comprises the simulation cutter device that can bear radial force and axial force simultaneously, is provided with the displacement sensor that detects its displacement on the simulation cutter device, and simulation cutter device comprises handle of a knife 101, handle of a knife A shank nut 102 is installed at one end of the shank nut 102, and a bearing 103 (that is, a tapered roller bearing or an angular contact ball bearing) capable of bearing radial force and axial force is set on the shank nut 102. The outer side of the bearing 103 is installed with The shaft sleeve 104 matching the size of the bearing 103 is provided with a stepped hole matching the size of the outer ring of the bearing 103 inside the shaft sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com