A continuous circulating operation of plastic pipe mold cooling device

A cooling technology for plastic pipes and molds, which is applied in the field of circulation devices, which can solve the problems that the equipment cannot run continuously and stably, affect the high-speed and high-efficiency operation of the equipment, and achieve the effects of not easy to leak, small movement impact, and eliminate malfunctions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

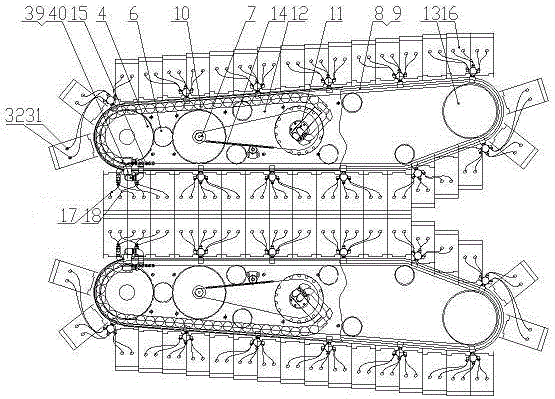

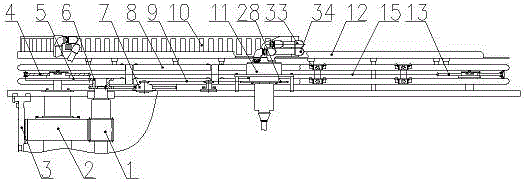

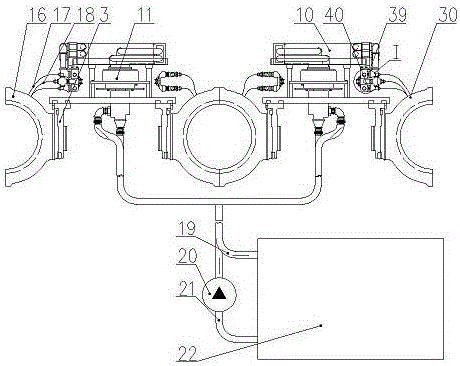

[0029] Examples such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of plastic pipe mold cooling device of continuous cycle operation comprises at least two groups of plastic pipe moulds, and each group of molds comprises at least two mold bodies 16 that circulate along circular tracks respectively, and the mold bodies 16 on the two groups of moulds— Correspondingly, each mold body 16 is provided with a cooling water cavity 30 inside, and the cooling water cavity 30 is connected with a cooling water movement pipeline.

[0030] Each group of molds is equipped with a power drive device that drives the molds to circulate along the circular track.

[0031] The power drive device includes a large driving sprocket 4 and a large driven sprocket 13 , and the large driving sprocket 4 and the large driven sprocket 13 are connected through a pipeline chain 15 .

[0032] A mold mounting seat 3 is connected to the pipeline chain 15 , and the mold body 16 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com