Stator Segmented Permanent Magnet Linear Motor Direct Drive Lifting System Using Distributed Power Supply

A permanent magnet linear motor and distributed power supply technology, which is applied in the direction of propulsion systems, electrical components, electromechanical devices, etc., can solve the problems of occupying building space, accelerating the slide of movers and cars, and poor anti-interference ability, so as to achieve the guarantee Stable operation and low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

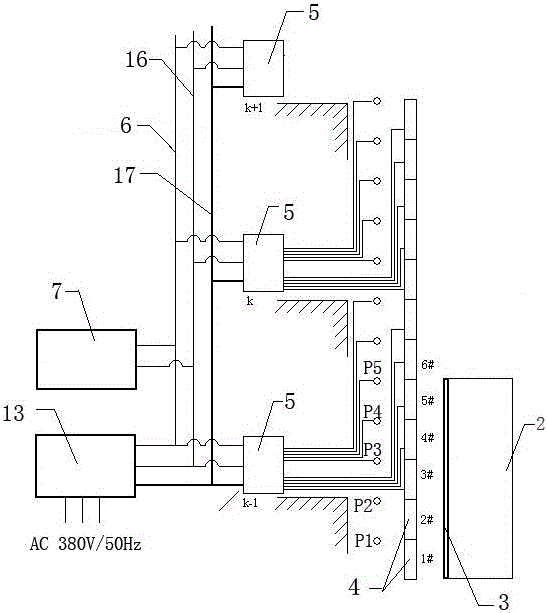

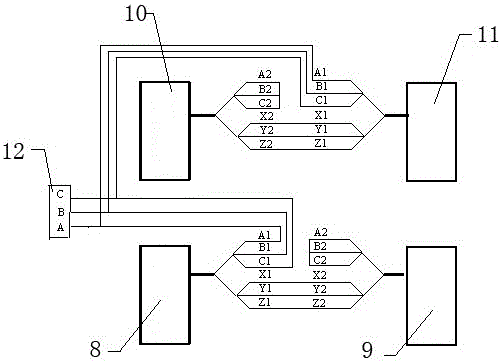

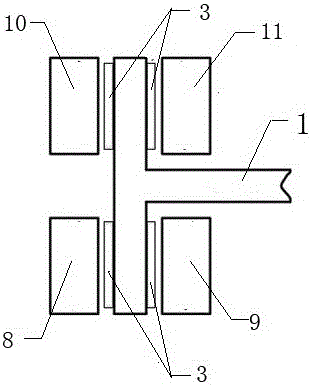

[0026] Such as figure 1 , figure 2 and image 3 As shown, the present invention comprises permanent magnet linear motor and the car 2 that is arranged on the car frame 1, and the car frame 1 is provided with permanent magnet linear motor mover permanent magnet 3, and the permanent magnet linear motor stator winding is formed from bottom to bottom. The stator windings 4 of multiple sets of unit motors set on the computer are composed of multiple control modules 5 connected to the control master station 7 through the field bus 6 to execute the commands of the control master station 7. The control module 5 can use a single-chip microcomputer, and the control master station 7 is provided with PC. The stator windings 4 of each group of unit motors include a first U-shaped permanent magnet linear motor stator winding and a second U-shaped permanent magnet linear motor stator winding with openings facing inward. Each U-shaped permanent magnet linear motor stator winding includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com