Reclaimed rubber material and manufacturing technique thereof

A technology of regenerated rubber and rubber powder, which is applied in the field of new polymer materials, can solve the problems of TPR shoe soles, such as non-folding resistance, high energy consumption, and low material utilization rate, so as to reduce and precautions, reduce process steps, and increase production efficiency. Effect

Inactive Publication Date: 2013-12-04

泉州市华阳鞋材科技有限公司

View PDF1 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

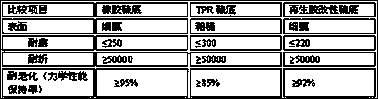

But the TPR sole is not resistant to folding, easy to age, and has low wear resistance

The molding of rubber soles is slow, the utilization rate of materials is low, and the energy consumption is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 5

[0036] In embodiment 5, step 3 is omitted, and other steps remain unchanged.

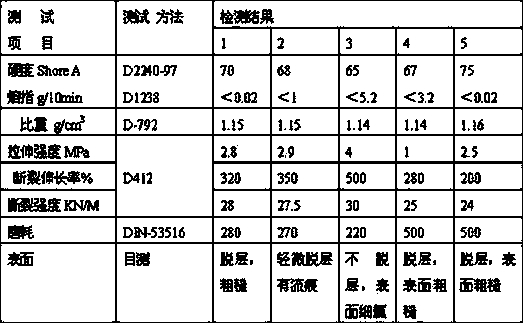

[0037] Since a large amount of reclaimed rubber powder is used in the formula, the fluidity is relatively low, so the twin-screw should strengthen the mixing effect in the arrangement of the screw structure, so that the rubber powder can be evenly distributed in the matrix resin SBS, so that it has good processing performance .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

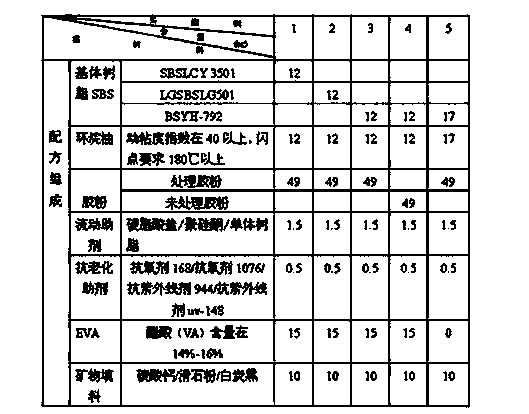

The invention relates to reclaimed rubber material and a manufacturing technique thereof and discloses the reclaimed rubber material. The raw material formula of the reclaimed rubber material comprises the following components in part by weight: 12 parts of matrix resin SBS, 12 parts of naphthenic oil, 1.5 parts of flow promotor, 10 parts of mineral filler, 49 parts of rubber powder, 15 parts of EVA and 0.5 parts of anti-aging promotor. The reclaimed rubber material provided by the invention not only makes full use of the characteristics of high elasticity, aging resistance, temperature and cold resistance of reclaimed rubber but also makes use of the characteristics of thermoplastic processing, environmental friendliness, energy conservation and high productivity of the matrix resin SBS. Therefore, the reclaimed rubber material conforms to the strategy of sustainable development better.

Description

technical field [0001] The invention relates to a new polymer material, in particular to a regenerated rubber material, and also relates to a manufacturing process of the material. Background technique [0002] my country has always been a big country in the use of rubber, but 70% of my country's rubber resources depend on imports, and it is a country with serious shortage of rubber resources. The recycling of waste rubber powder has effectively improved the utilization rate of rubber resources and eased the shortage of rubber materials in my country. Especially since the Fourth Plenary Session of the 16th CPC Central Committee put forward "vigorously develop circular economy and build a conservation-oriented society", China's waste rubber powder recycling industry has developed by leaps and bounds, and has successfully laid the foundation for the recycling of waste rubber powder. status of a great power. In 2006, China's rubber powder output reached 300,000 tons, an incre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L21/00C08L23/08C08L53/02C08L83/04C08K13/02C08K3/36C08K5/01C08K5/098C08K3/26C08K3/34A43B13/04

Inventor 黄百澍黄劲煌张正筹

Owner 泉州市华阳鞋材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com