Non-welding-connecting-key steel-concrete combined structure of outwards-folded lug plates

A combined structure, no welding technology, applied in building structures, buildings, etc., can solve the problems of stress concentration, easy fatigue, welding deformation, etc., and achieve the effect of strong fatigue resistance and excellent shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

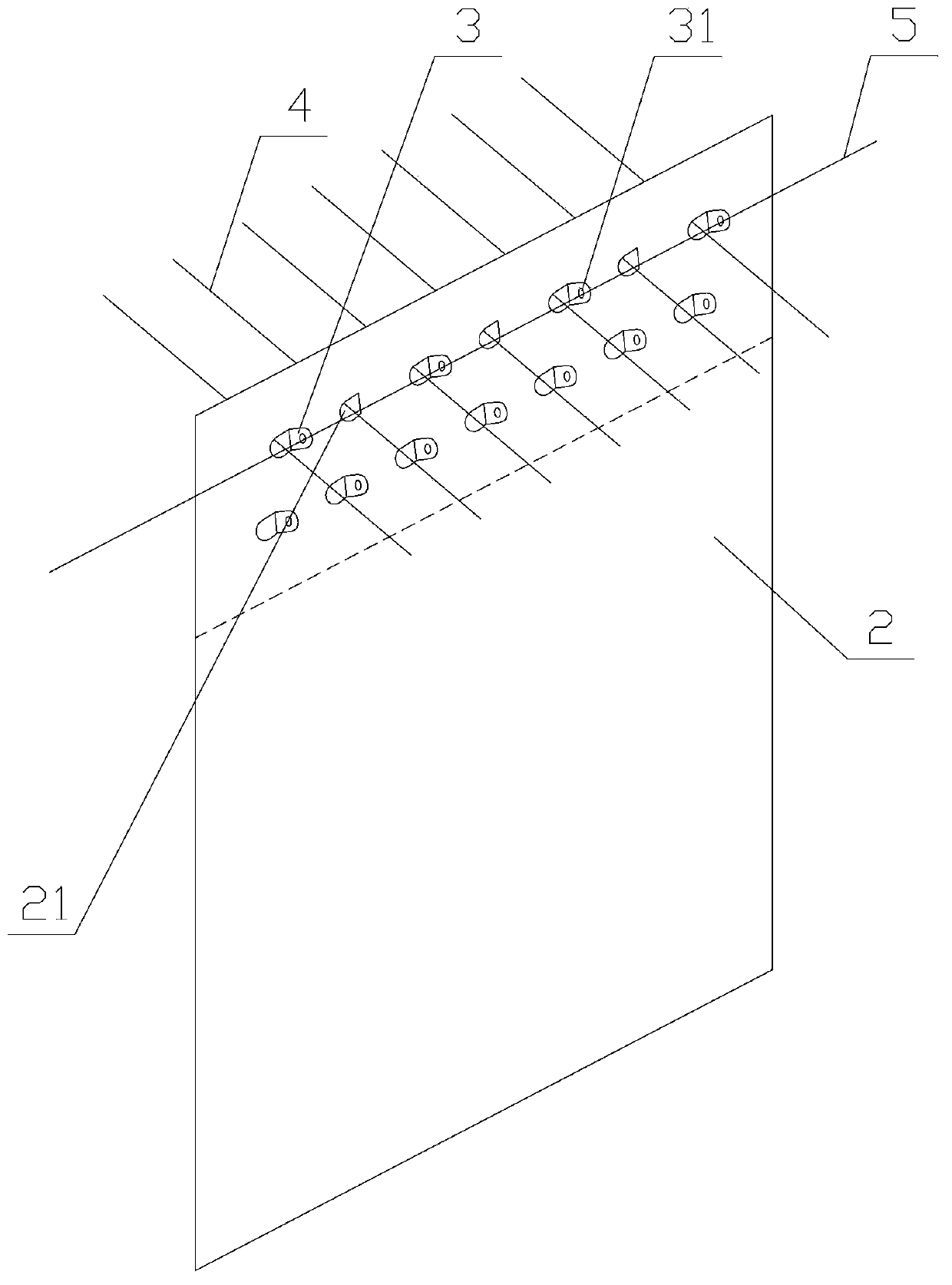

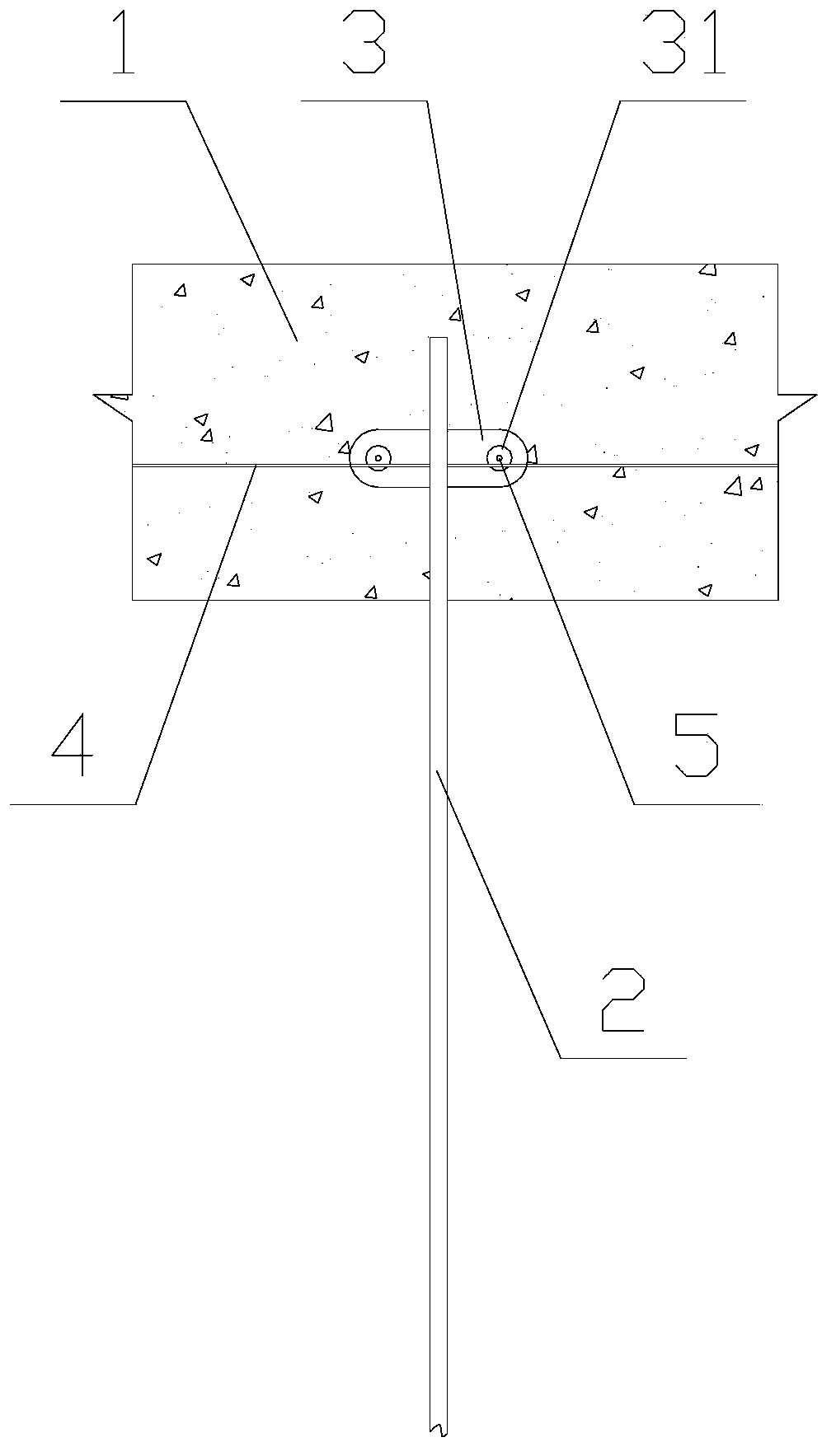

[0023] The steel-concrete composite structure without welded connection key of the turned-out lug plate, such as figure 1 , 2 As shown, it includes a steel plate 2, an everted lug 3 and concrete 1. The said everted lug 3 is formed by cutting the steel plate 2 and then turning it out. , the eversion ear plate 3 is more than two pieces, and the eversion ear plate 3 is poured in the concrete.

[0024] The everted lugs 3 are located on both sides of the steel plate 1 . A through hole 31 is provided on the everted ear plate 3 . The through hole 31 is pierced with a through steel bar 5 . Surplus hole reinforcing bar 4 is worn in surplus hole 21.

[0025] The remaining hole 21 is pierced with the reinforcing bar 4 for the remaining hole, and the reinforcing bar 5 and the reinforcing bar 4 for the remaining hole are intersected.

[0026] The radius of the corner between the everted ear plate and the steel plate is 5 times the thickness of the plate. The eversion ear plate is for...

Embodiment 2

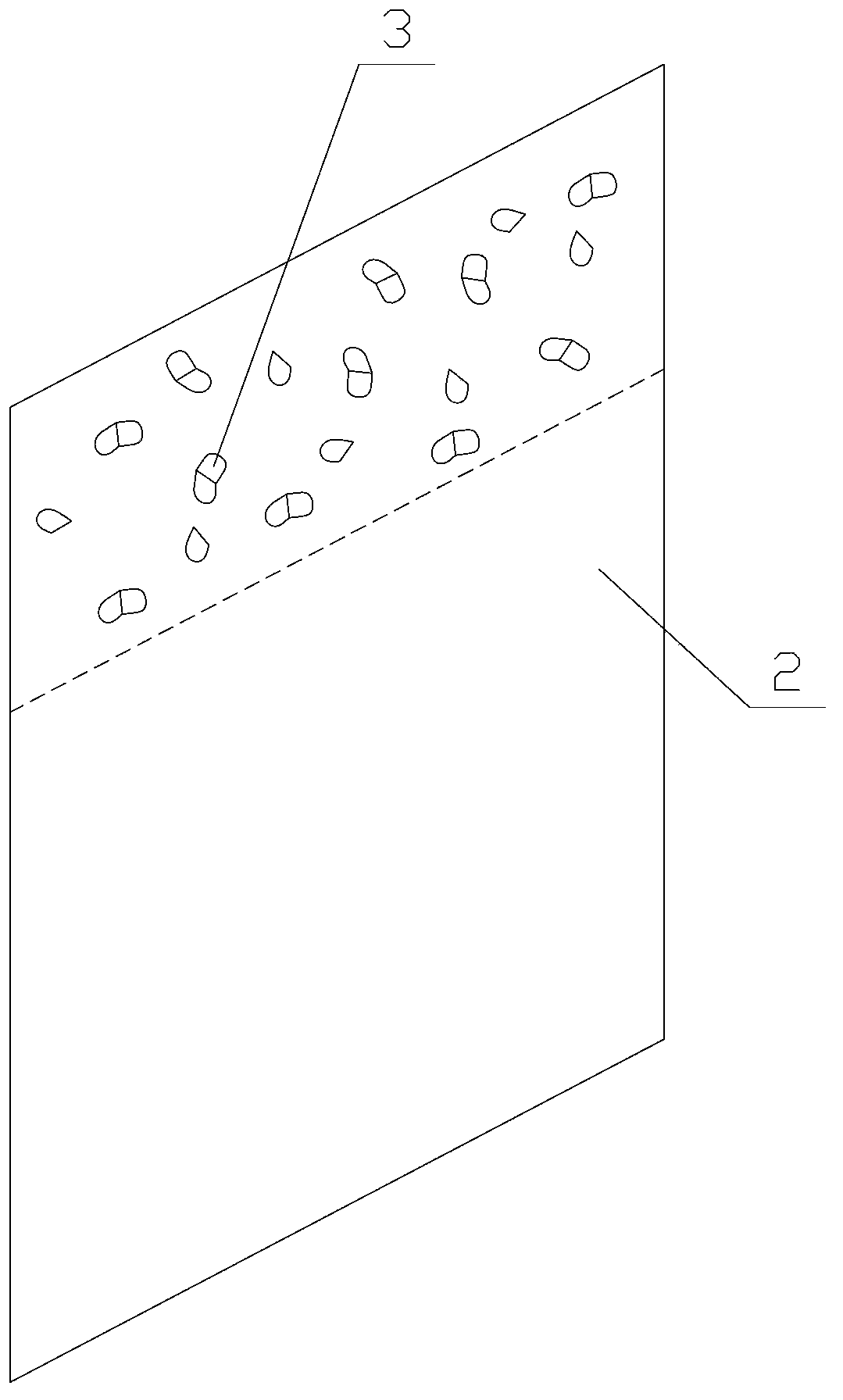

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the minimum included angle between the plane where the eversion ear plate is located and the plane where the steel plate is located is 0°-90°. If calculated according to the angle of 180°, the optimal angle between the plane of the everted lug plate and the plane of the steel plate is 30°-150°.

[0030] The minimum included angle between the plane where the lugs are turned outward and the horizontal plane is 0°-90°. The turning direction of the everted ear plate 3, except for the part that needs to pass through the steel bar 5 and the remaining hole steel bar 4, is regularly distributed. The rules are in any orientation. Such irregular random arrangement is more conducive to the eversion lug plate 3 to improve the connection strength between the steel plate and the concrete, and to play a better shear resistance effect.

[0031] The radius of the corner between the everted ear ...

Embodiment 3

[0033] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the steel plate 2 is a corrugated steel web. The radius of the corner between the everted ear plate and the steel plate is 18 times the thickness of the plate. If the corner radius is too small, the steel plate will be severely damaged, and if the corner radius is too large, it will not be able to effectively resist shear force or directly shear concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com