Cooling water circulating system

A circulation system and cooling water technology, applied in the field of circulation system, can solve the problems of not being environmentally friendly, unable to meet the needs of heat exchange, and consuming large electric energy, and achieve the effect of no pollution, simple structure, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

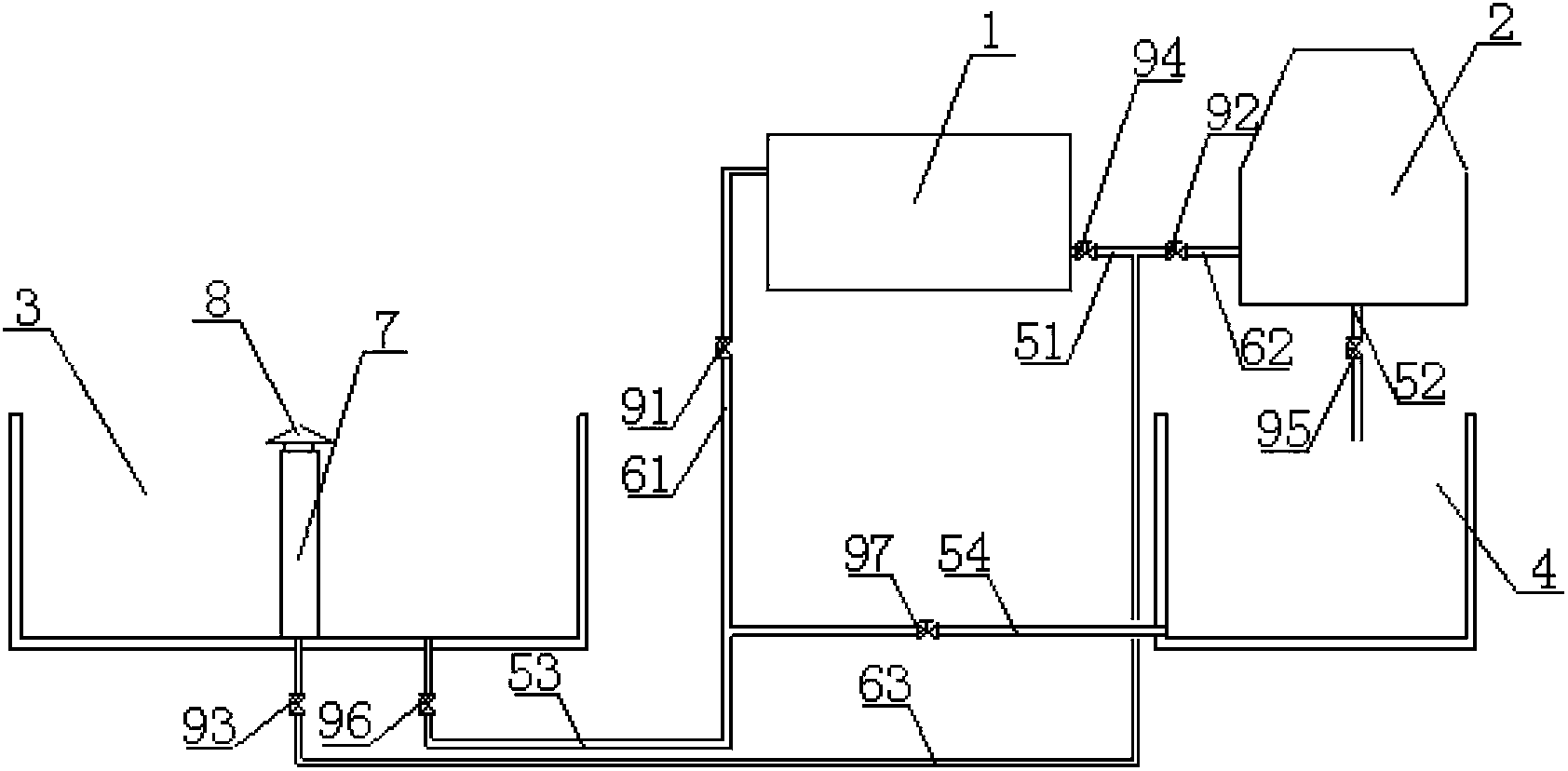

[0017] Embodiment 1 of the present invention: as figure 1 As shown, the cooling water circulation system includes a condenser 1, a cooling water tower 2, an outdoor reservoir 3 and an indoor reservoir 4, and the outlet pipe A51 of the condenser 1 is respectively connected to the water inlet pipe B62 of the cooling tower 2 and the outdoor reservoir 3 The water inlet pipe C63 of the cooling water tower 2 is connected to the indoor reservoir 4; the water inlet pipe A61 of the condenser 1 is respectively connected to the outlet pipe D54 of the indoor reservoir 4 and the outlet pipe C53 of the outdoor reservoir 3; The water storage tank 3 is provided with a cooling water spray pipe 7; the cooling water spray pipe 7 is located at the bottom center position of the outdoor water storage tank 3, and the water inlet pipe C63 of the outdoor water storage tank 3 is connected with the bottom of the cooling water spray pipe 7; The top of the water spray pipe 7 is provided with a water block...

Embodiment 2

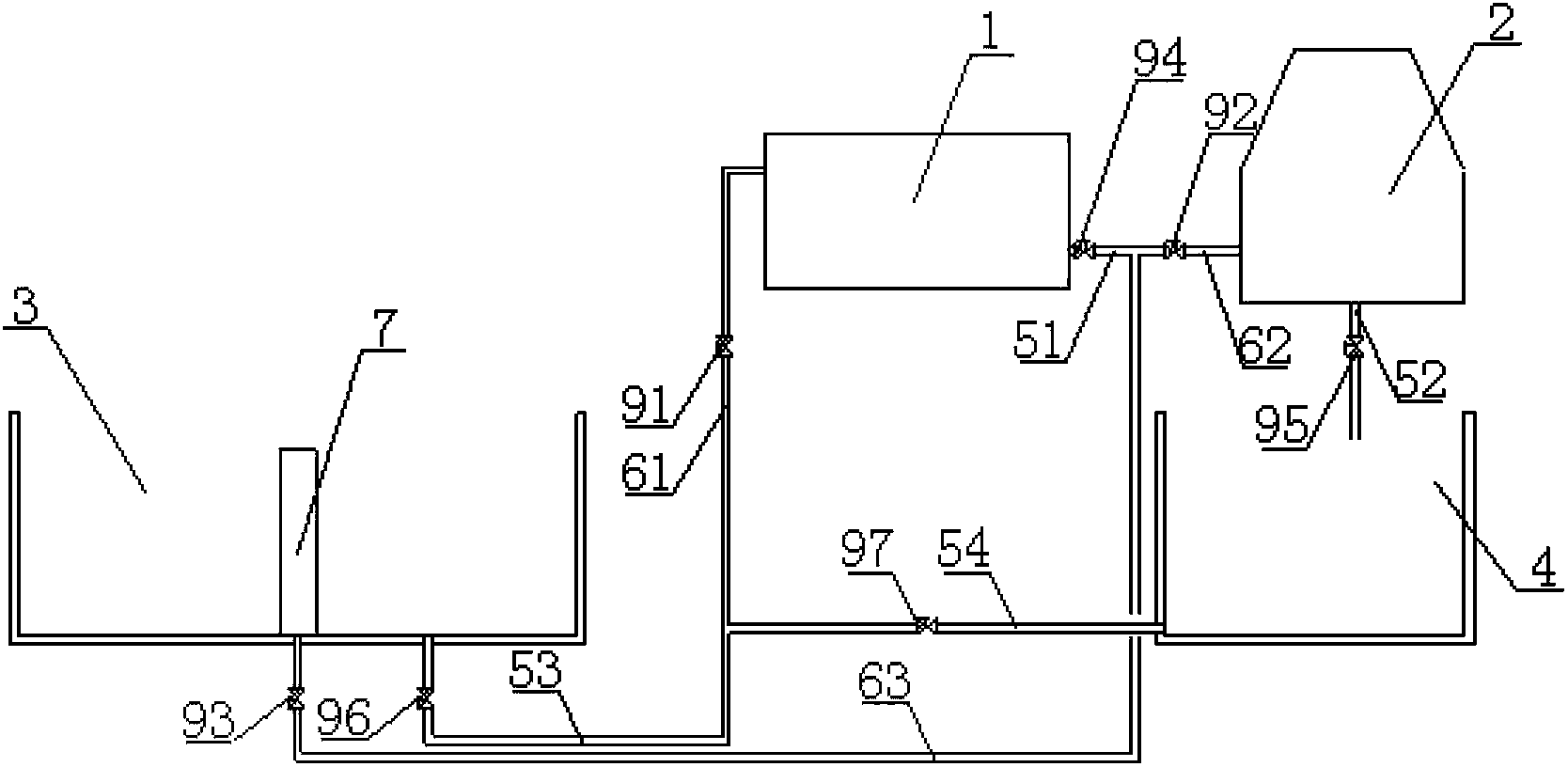

[0018] Embodiment 2 of the present invention: as figure 2 As shown, the cooling water circulation system includes a condenser 1, a cooling water tower 2, an outdoor reservoir 3 and an indoor reservoir 4, and the outlet pipe A51 of the condenser 1 is respectively connected to the water inlet pipe B62 of the cooling tower 2 and the outdoor reservoir 3 The water inlet pipe C63 of the cooling water tower 2 is connected to the indoor reservoir 4; the water inlet pipe A61 of the condenser 1 is respectively connected to the outlet pipe D54 of the indoor reservoir 4 and the outlet pipe C53 of the outdoor reservoir 3; The water storage tank 3 is provided with a cooling water spray pipe 7; the cooling water spray pipe 7 is located at the bottom center of the outdoor water storage tank 3, and the water inlet pipe C63 of the outdoor water storage tank 3 is connected with the bottom of the cooling water spray pipe 7; The water pipe A61 is provided with a valve A91, the water inlet pipe B6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com