Cement clinker preparation method and system

A technology for cement clinker and preparation system, which is applied in the field of building materials, can solve the problems of increasing production heat consumption, affecting clinker calcination, and decreasing fuel combustion efficiency, and achieves the effects of improving combustion efficiency, product quality, and calcination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a method for preparing cement clinker, which is a method of sending cement preheated and pre-decomposed raw meal into a rotary kiln and cooling it through a grate cooler to produce cement clinker. Or add water to the first section of the grate bed of the grate cooler, and the vaporized and decomposed product of the water enters the rotary kiln for burning cement clinker.

[0037] What is to be explained here is: atomized water vaporizes and decomposes rapidly at high temperature, and the vaporization and decomposition products of water can quickly participate in the combustion reaction of fuel and improve the combustion efficiency of fuel, thereby improving the calcination efficiency of clinker in the rotary kiln and improving the product quality. quality.

[0038] The above scheme can realize the preparation of cement clinker and improve the combustion efficiency in the rotary kiln. On this basis, the preferred scheme is...

Embodiment 1

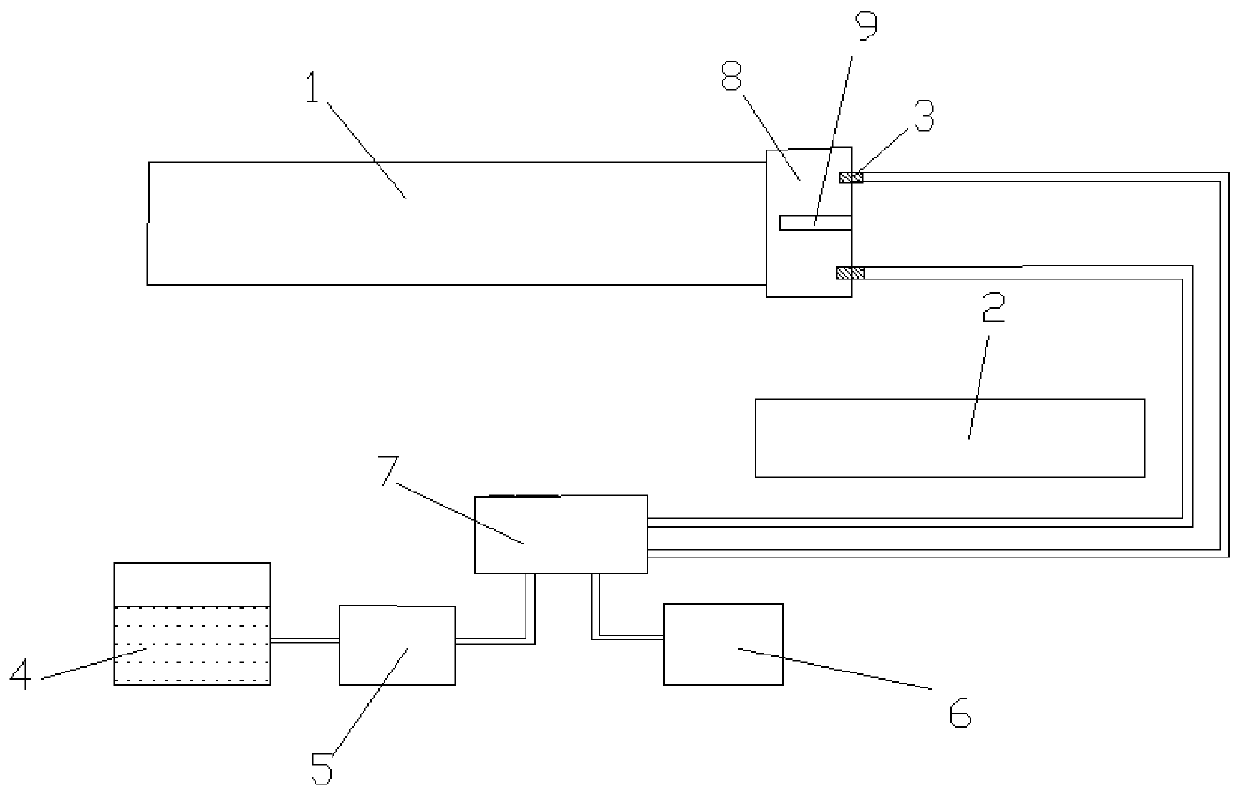

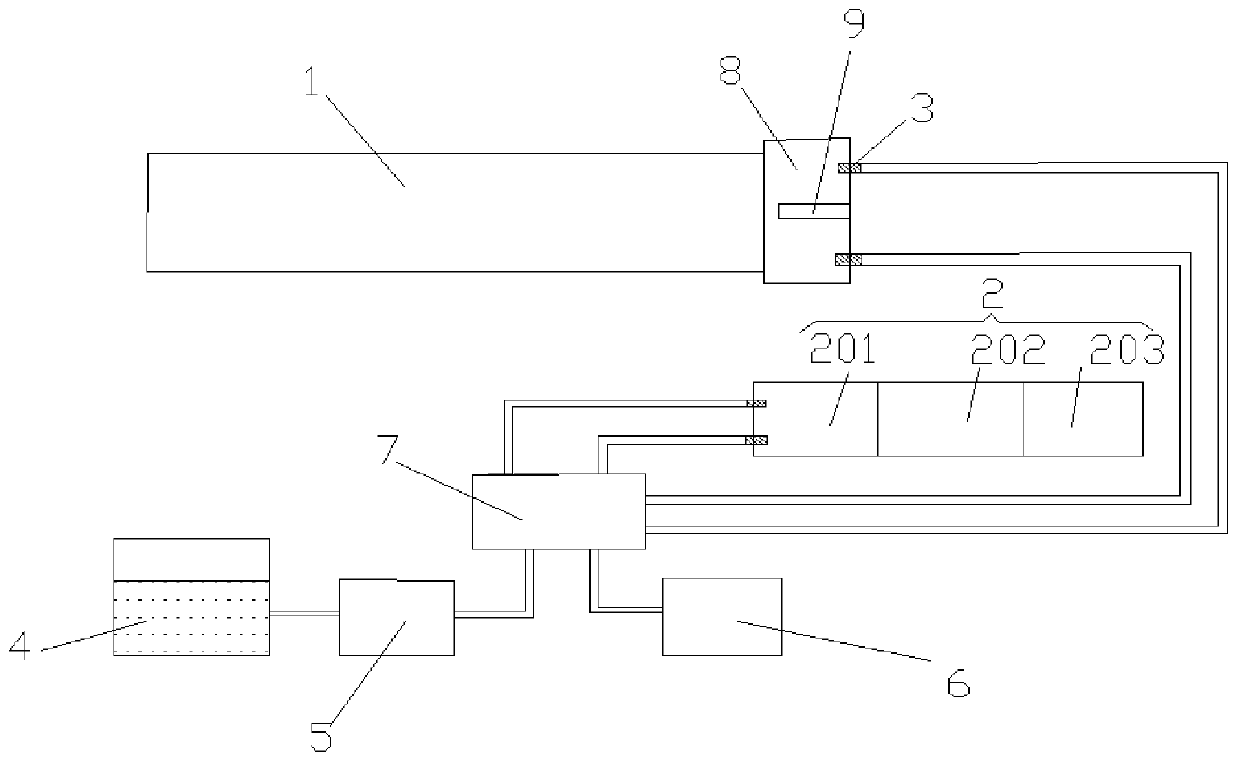

[0070] The embodiment of the present invention provides a cement clinker preparation system, figure 1 It is a schematic structural diagram of the cement clinker preparation system in this embodiment, as figure 1 As shown, the system includes a rotary kiln 1 and a grate cooler 2, the rotary kiln 1 includes a kiln head cover 8, a burner 9 is provided inside the kiln head cover 8, and a water adding device 3 is provided on the side of the kiln head cover 8, which is used Add water to the kiln hood;

[0071] What should be explained here is that there is no limit to what kind of water adding device to choose. The atomization spray gun is preferred. The atomized water vaporizes and decomposes rapidly at high temperature, and the vaporization and decomposition products of water can quickly participate in the combustion reaction of fuel, improving Improve the combustion efficiency of fuel, thereby improving the calcination efficiency of clinker in the rotary kiln and improving produ...

Embodiment 2

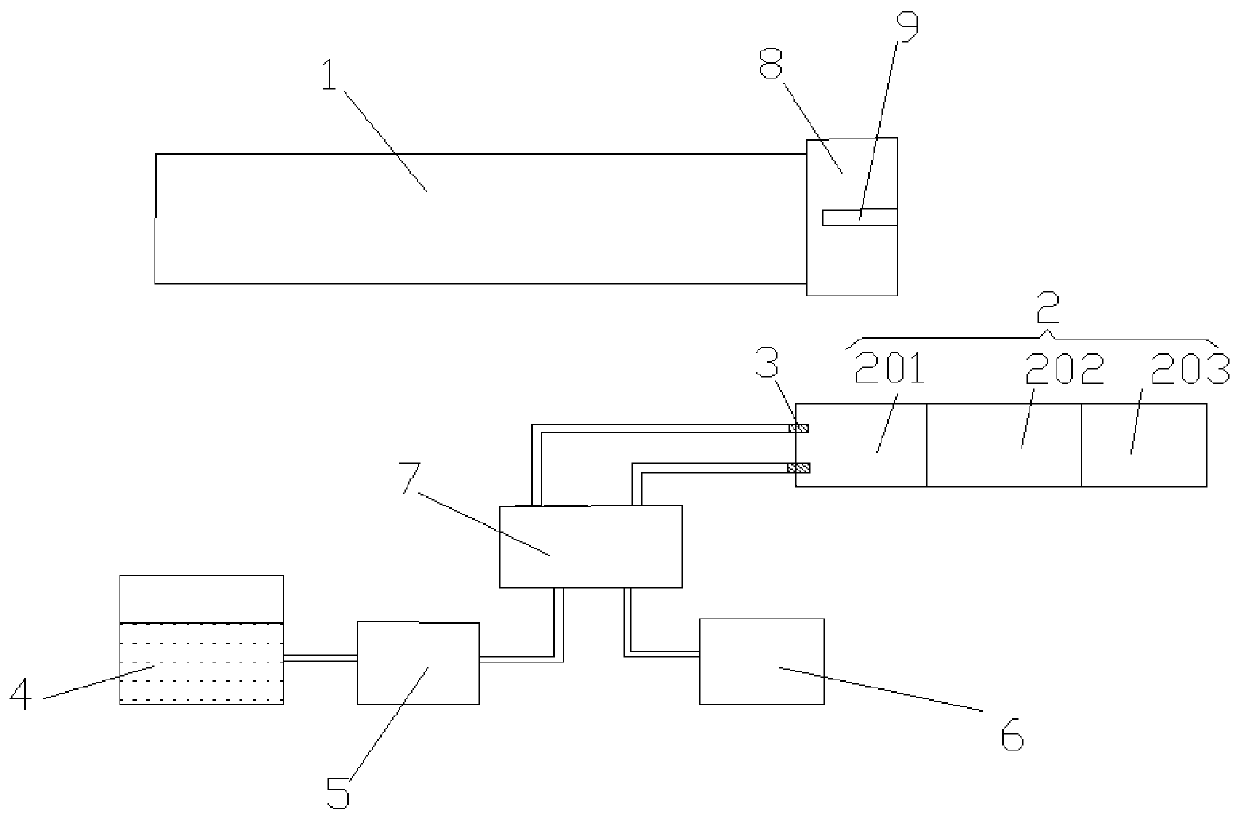

[0080] The difference with Embodiment 1 is that the atomizing spray gun of the present embodiment is arranged on the top of a section of the fixed bed of the grate cooler, figure 2 It is a schematic structural diagram of the cement clinker preparation system of this embodiment, as figure 2 As shown, the system includes a rotary kiln 1 and a grate cooler 2. The grate cooler 2 includes a first stage 201 of a grate cooler, a second stage 202 of a grate cooler, and a third stage 203 of a grate cooler. The rotary kiln 1 includes a kiln head cover 8. The inside of the head cover 8 is provided with a burner 9, and an atomizing spray gun 3 is also provided on the fixed bed of the first section of the grate cooler, which is used to add water to the fixed bed;

[0081] It should be explained here that the atomized water vaporizes and decomposes rapidly at high temperature, and the vaporization and decomposition products of water can quickly participate in the combustion reaction of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com