Preparation method of melt-blown cloth with three-dimensional array taro bulge structure and melt-blown cloth

A technology of three-dimensional array and melt-blown cloth, which is applied in the direction of non-woven fabrics, heating/cooling fabrics, thorn patterns, etc. The product cannot present the three-dimensional shape and other problems, so as to achieve the effect of enhancing the effect of electret treatment, easy to promote and use, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

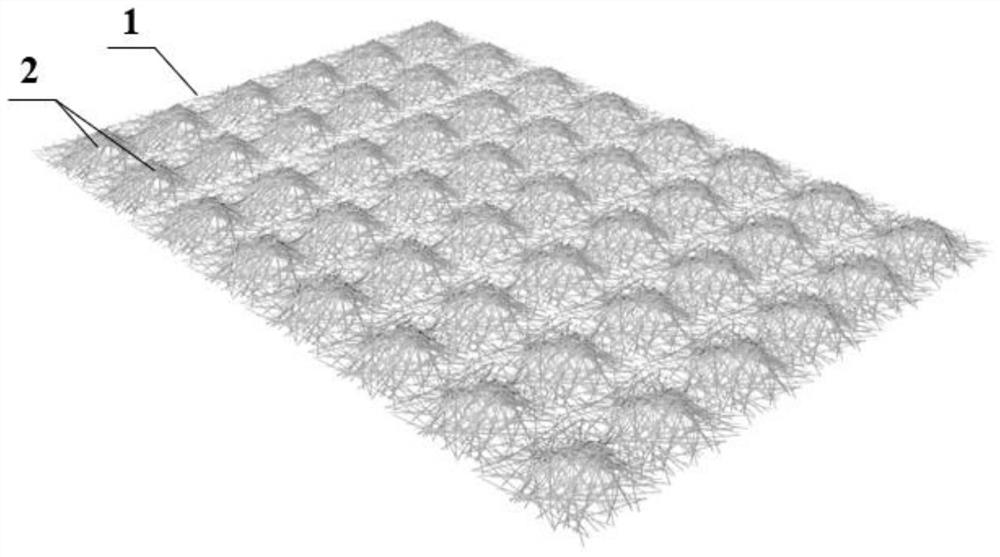

[0033] At the same time, the present application embodiment also provides a method of preparing a melting cloth having a three-dimensional array microcuty structure, which comprises:

[0034] S1, a meltblown fabric having a two-dimensional mesh structure is formed;

[0035] The fiber has no regular dense dispersion arrangement with a meltblown fabric having a two-dimensional mesh structure;

[0036] S2, modify the apparent shape of the meltblown fabric body, forming a meltblown fabric having a three-dimensional arrays.

[0037] In some embodiments of the present application, the meltblown surface of the three-dimensional structure is obtained by the circular two-dimensional structure of the bottom surface of the meltblown body, and the disorderly arrangement in the surface three-dimensional structure is arranged. The fineness is thinner than the fiber in the two-dimensional surface.

[0038] In order to make the present invention more obvious, it is described in detail by the pref...

Embodiment 1

[0040] Polypropylene fibers in which the fiber diameter of 2 μm from the meltblown device is ordered to form a polypropylene fiber meltblown fabric having a two-dimensional mesh structure without a regular dispersion, and is processed in a hot pressing device with the morphology of the martial art. The meltblown fabric having a three-dimensional array of scottic micro-convex structure is obtained. Among them, the bottom surface radius r of the three-dimensional arrays mutant structure unit is 1 mm, the protrusion height H is 1 mm, and the spacing of the sausimus structure unit is 0.6 mm, the array is parallel.

[0041] The experimental test was compared to: a polypropylene fiber melt spray fabric having a three-dimensional array of sagus structures using the present invention increased by approximately 33%, a gas resistance than a polypropylene fiber having a conventional two-dimensional structure The rate is reduced by about 16%, and the particle capture capacity is increased by ...

Embodiment 2

[0043] The polylactic acid fibers that are discharged from the meltblown device having a fiber diameter of 3.5 μm make it unregistered to a surface of a rigid-forming shape having a syndrome of a ruthenium in which it has a three-dimensional array of rolling structures. . Among them, the bottom surface radius r of the three-dimensional arrays structure unit is 0.4 mm, the protrusion height H is 0.8 mm, and the male chronological unit spacing L is 1 mm, the array is a vertical.

[0044] The experimental test is compared: polylactic acid fibers having a three-dimensional arraystructure structure according to the present invention increased by approximately 36% compared to the polylactic acid fibers corresponding to conventional two-dimensional structures, gas The resistance is reduced by about 24%, and the particle capture capacity is increased by about 35%, and the service life is extended to about 37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com