Washing machine cover impact test device

A technology of impact test and washing machine, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of no special measuring tool for measuring the test height, no weight adjustment function for heavy objects, poor safety and accuracy, etc., and achieve simplified machinery Intensive operation process, high accuracy, and the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

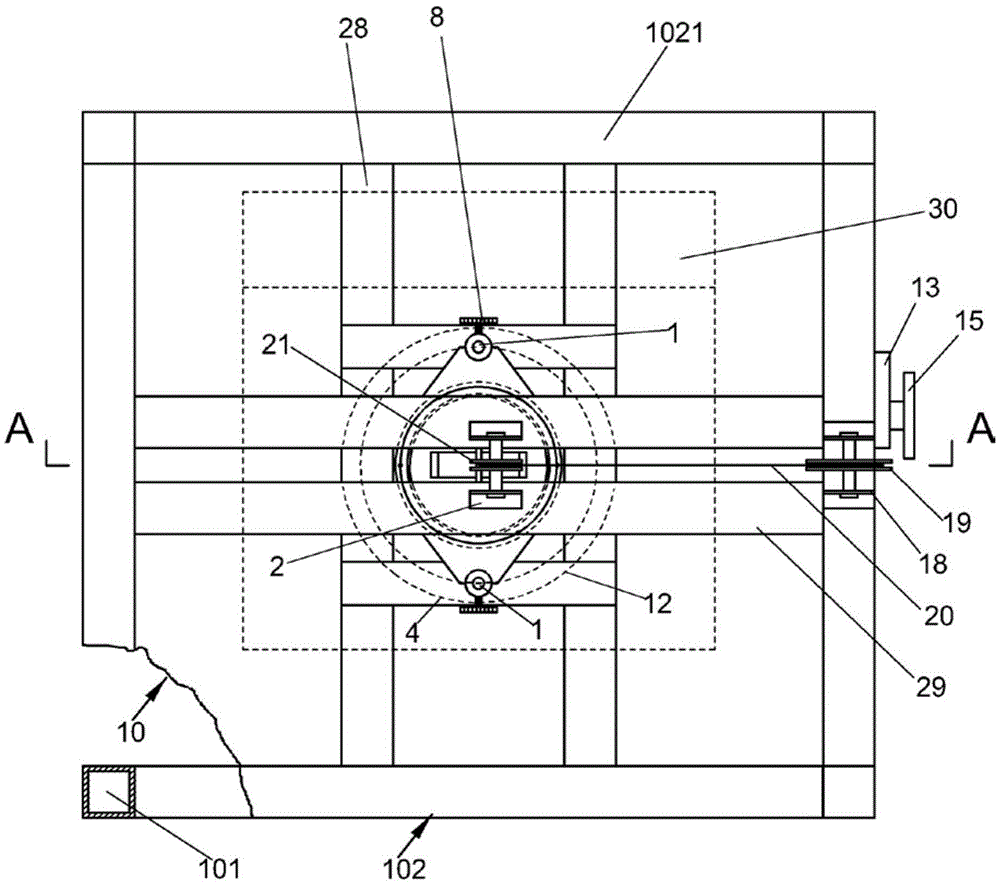

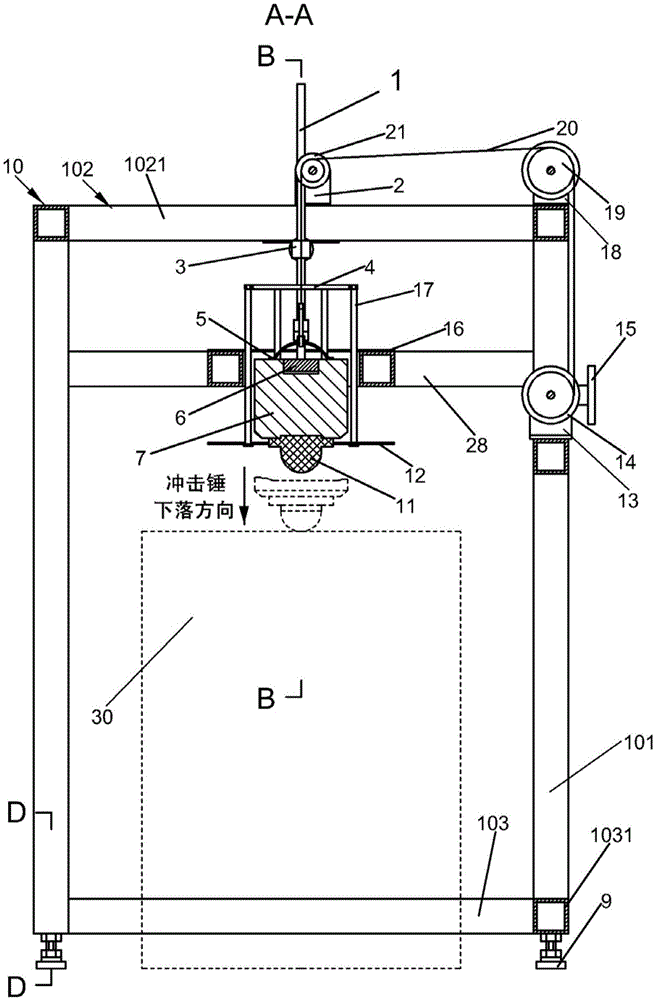

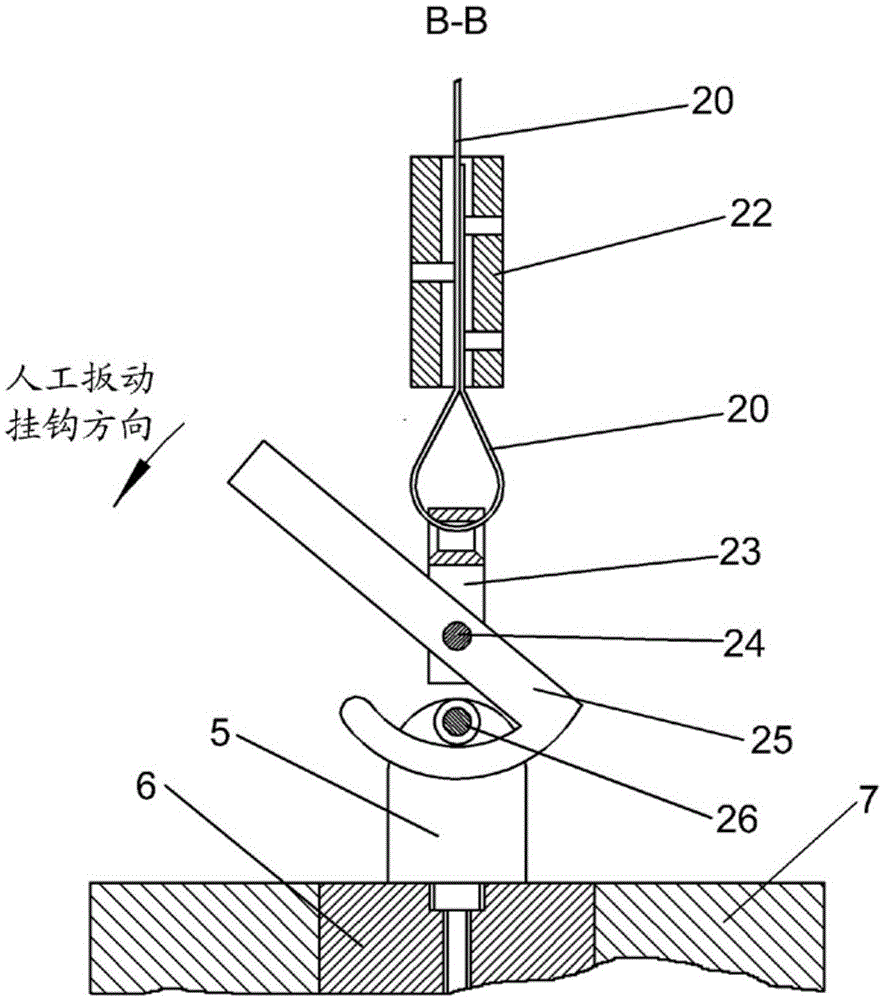

[0030] see Figure 1-7 , washing machine cover impact test device, including two cylindrical guide rails 1, small fixed pulley bracket 2, cylindrical guide rail upper support frame 3, guide protection mechanism, impact hammer hoisting mechanism, impact hammer body 7, brake handle 8, support frame 10 , front rubber impact head 11, wire rope sheave 14, lifting handle 15, cylindrical guide rail lower support frame 16, large fixed pulley bracket 18, large fixed pulley 19, traction wire rope 20, small fixed pulley 21 and special gauge 27;

[0031] Described support frame comprises four upright columns 101, top frame 102 and underframe 103, and described top frame 102 is made of four upper beams 1021, and described underframe 103 is made up of four lower beams 1031; In the middle of described upright column 101, An intermediate bracket 28 is arranged at a position between the upper beam 1021 and the lower beam 1031, and the center of the intermediate bracket 28 is provided with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com