Storage conveyer car with automatic tracking and obstacle avoiding functions

A technology for automatic tracking and transport of trolleys, applied in two-dimensional position/channel control, etc., can solve the problems of high cost, large investment in human resources, and high requirements for drivers' driving skills, and achieve high automation level and high detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

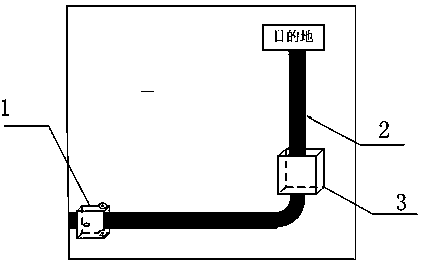

[0020] Such as figure 1 As shown, a 0.15-meter black line 2 is set on the warehouse floor, and the rest of the ground is painted white. The storage and transportation trolley 1 automatically tracks along the black line 2 to reach the destination and then turns 180 degrees on the spot, and encounters an obstacle 3 on the way. Automatically avoid obstacles.

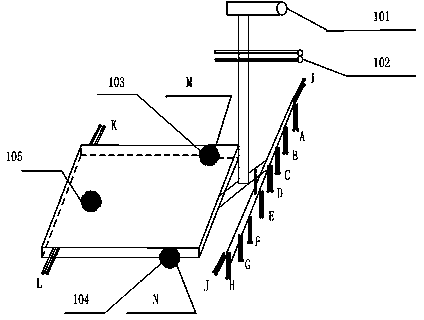

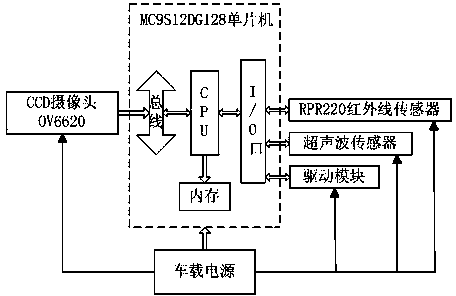

[0021] Such as figure 2 As shown, this embodiment discloses a storage and transport trolley for automatic tracking and obstacle avoidance, which includes a trolley body on which a camera 101, a single-chip microcomputer, an ultrasonic sensor 102, a drive module, an on-board power supply and 12 pairs of infrared sensors A, B, C, D, E, F, G, H, I, J, K, L, wherein the camera 101 and the ultrasonic sensor 102 are installed on the front of the car, and the emission direction is directly in front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com