A Generation Algorithm of Microscopic Digital Model of Cement Paste

A technology of cement slurry and microscopic model, which is applied in the fields of electrical digital data processing, calculation, special data processing application, etc., can solve the problem of ignoring the internal connection of concrete, and achieve the effect of improving the recognition efficiency and improving the recognition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in combination with specific embodiments.

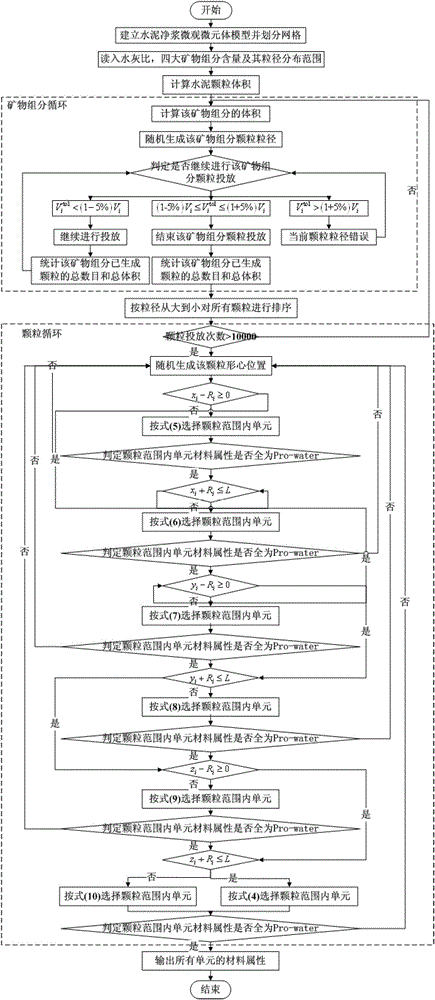

[0058] The main step flow chart of the present invention is as figure 1 Shown, the specific implementation method of the present invention is illustrated below in conjunction with the accompanying drawings:

[0059] Step 1, the establishment of a side length of L μm cement slurry microscopic cube model, the unit grid size is equal to 1 μm;

[0060] Step 2, read in the water-cement ratio of the simulated cement slurry, the content of the four major mineral components and their particle size distribution;

[0061] Step 3, calculate cement particle volume by formula (1);

[0062] Step 4, cycle through the four types of mineral components, and calculate the volume V of the mineral components i , and generate the particle size of each particle of the mineral component in turn according to its particle size distribution requirements (unit μm, rounded):

[0063] Step 5, determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com