A kind of carbon nanotube conductive paste and preparation method thereof

A carbon nanotube and conductive paste technology, applied in the field of electrochemical materials, can solve the problems of truncated carbon nanotubes, low efficiency, poor dispersion effect, etc., and achieve the effects of stable and uniform properties, excellent electrical conductivity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

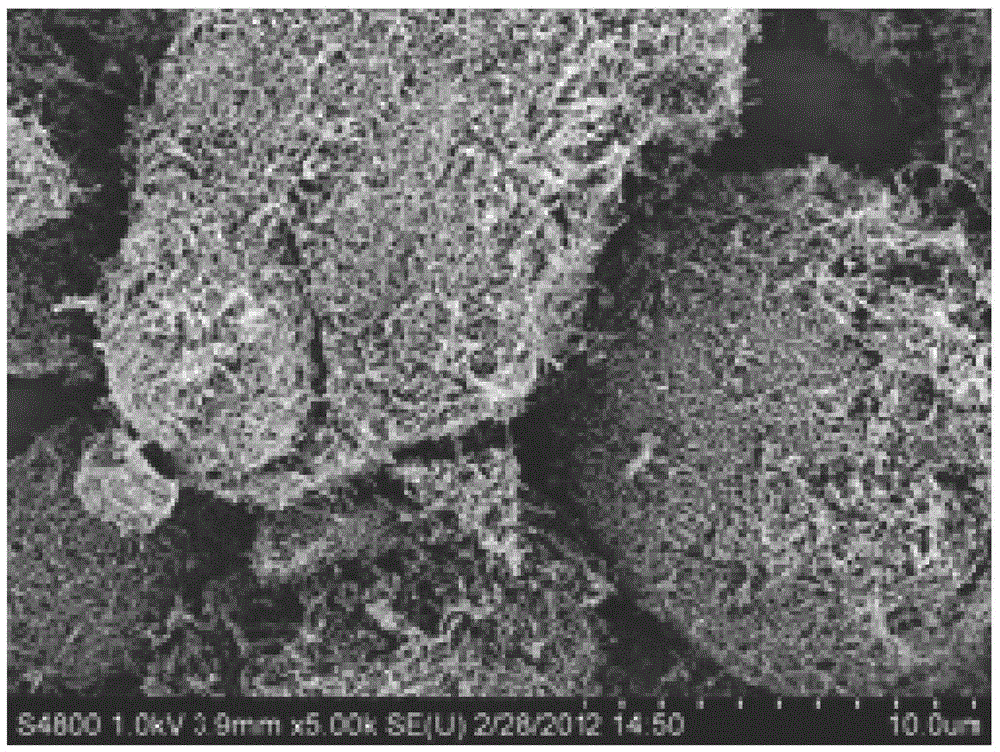

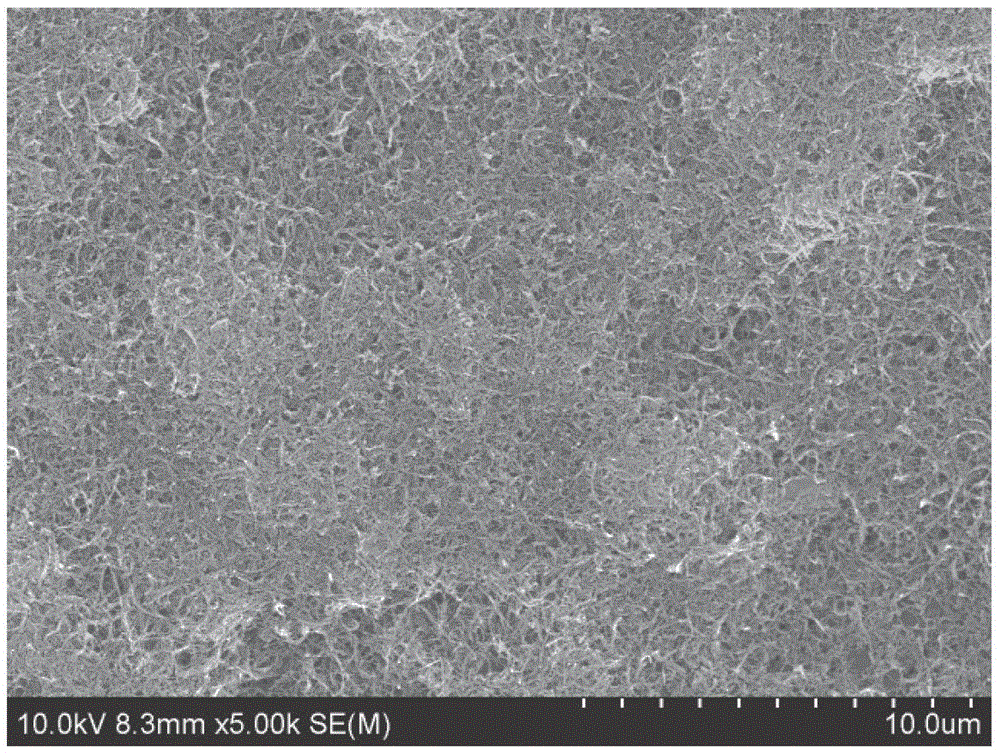

[0025] Example 1: 9.25kg of N-methylpyrrolidone was added into a 20-liter container as a solvent carrier, and 0.15kg of polyvinylpyrrolidone was added thereto as an auxiliary agent. Fully dissolve the polyvinylpyrrolidone in the N-methylpyrrolidone under the mechanical stirring condition of 6000rpm. Then, 0.6 kg of multi-walled carbon nanotubes are added in batches to the solution, and the rest of the carbon nanotubes are added after the added solid powder is fully wetted by the solvent. After all the additions were completed, mechanical stirring was continued for 15 minutes to obtain a pre-dispersed slurry. The carbon nanotube pre-dispersed slurry was transferred to a nano sand mill, and zirconia balls with a diameter of 1 mm were used to grind at 2400 rpm for 2 hours to obtain the carbon nanotube slurry.

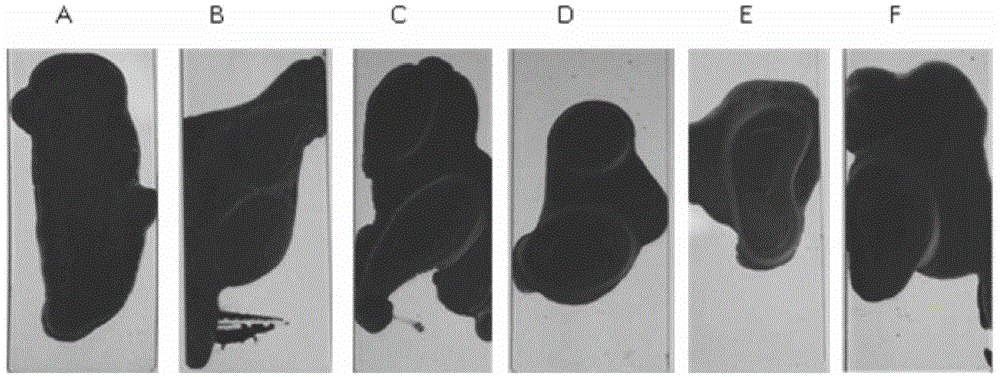

[0026] Carbon nanotube pre-dispersion slurry and hourly grinding slurry are coated on glass slides and dried. The photo is as follows image 3 shown. The stability of t...

Embodiment 2

[0027] Example 2: 9.4kg of water was added into a 20-liter container as a solvent carrier, and 0.1kg of hydroxymethylcellulose was added thereto as an auxiliary agent. Fully dissolve the hydroxymethylcellulose in water under the condition of 5000rpm mechanical stirring. Then add 0.17kg Super-p nano-acetylene black conductive agent and 0.33kg single-walled carbon nanotubes to the solution in batches, and then add the rest of the composite conductive agent after the added solid powder is fully wetted by the solvent. After all the additions were completed, mechanical stirring was continued for 15 minutes to obtain a pre-dispersed slurry. The carbon nanotube pre-dispersed slurry was transferred to a sand mill, and zirconia balls with a diameter of 0.3 mm were used to grind at 1800 rpm for 5 hours to obtain a carbon nanotube composite conductive slurry.

Embodiment 3

[0028] Example 3: 9.4 kg of deionized water was weighed in a 20-liter container as a solvent carrier, and 0.1 kg of polyvinylpyrrolidone was added therein as an auxiliary agent. Fully dissolve the polyvinylpyrrolidone in water under the condition of 3000rpm mechanical stirring. Then add 0.5 kg of multi-walled carbon nanotubes in batches to the solution, and add the rest of the carbon nanotubes after the added solid powder is fully wetted by the solvent. After all the additions were completed, mechanical stirring was continued for 15 minutes to obtain a pre-dispersed slurry. The carbon nanotube pre-dispersed slurry was transferred to a sand mill, and zirconia balls with a diameter of 0.6 mm were used to grind at 1500 rpm for 0.5 hour to obtain a carbon nanotube composite conductive slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com