Synchronous speed regulating method of reversely speed regulating frequency-converter

A frequency converter and synchronous adjustment technology, applied in electrical components, control systems, AC motor control and other directions, can solve the problems of low power factor, high manufacturing cost, less application, etc., achieve cost and volume reduction, save manufacturing power, adjust High-speed and high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

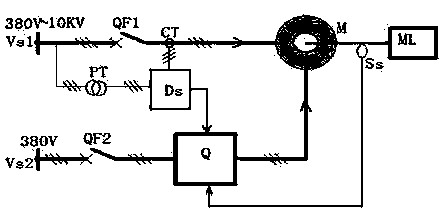

[0011] A synchronous speed regulation method of reverse speed regulation frequency converter, such as figure 1 As shown, it is characterized in that it is suitable for AC motors with excitable rotors, the mains power is directly connected to the stator coil of the motor through QF1, the motor current and voltage are connected to Ds through CT and PT, Vs2 is the main power supply of Q, and the system passes through Ds, Ss, Vs2 and other parameters are processed and calculated to determine the current size, frequency, phase angle, and phase sequence output to the rotor. The output of Q is current type, once its output current magnitude, frequency, phase angle and phase sequence are determined, it will not be affected by load characteristics and rotor induced electromotive force.

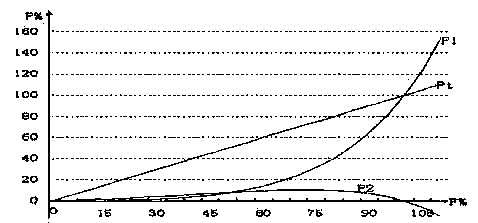

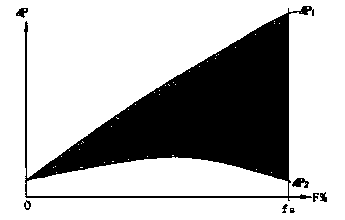

[0012] The speed regulation process is as follows: when the motor is running, the rotating magnetic field of the stator is fixed, that is, fs is fixed, and the rotating magnetic field of the rotor cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com