Automatic speed regulation method for range hood

A range hood, automatic speed regulation technology, applied in the direction of removing oil fume, heating method, household heating, etc., can solve the problems of cumbersome circuit processing process, reducing production cost, oil fume blocking, etc., and achieves a simple and easy control method, Solve the problem of consistency, stable and reliable effect of speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

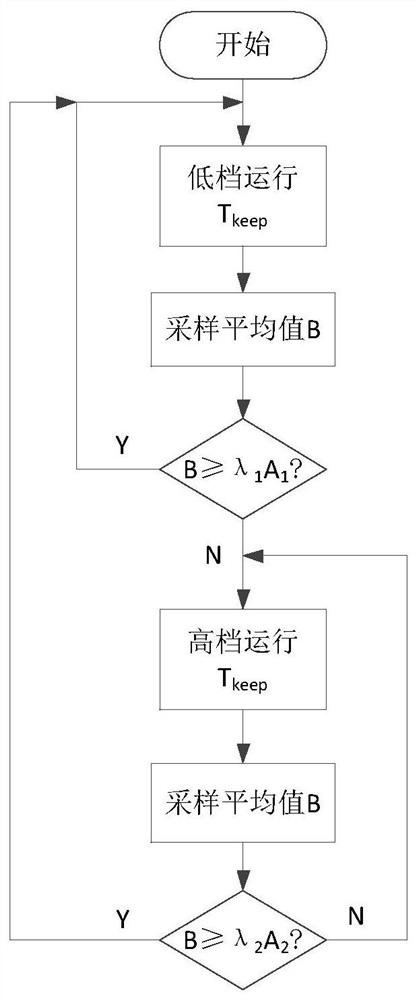

[0019] Such as figure 1 As shown, this embodiment discloses an automatic speed regulation method for range hoods. The automatic speed regulation method adopts the existing wind pressure detection circuit and is realized through the following steps:

[0020] (1), the program is started, and the current value of the fan of the range hood is detected in real time; wherein, the fan of this embodiment uses AC voltage to work, and during the working process, the current value of the fan will change with whether the flue is unobstructed, When the flue is unobstructed, the fan rotates fast, and the working current of the fan is large; when the flue is blocked, the resistance of the fan is large, and the speed drops, at this time, the working current of the fan becomes smaller;

[0021] (2) After the range hood is turned on, it runs at low gear by def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com