BGA (Ball Grid Array) ball embedding method using SMT (Surface Mounting Technology) chip mounter

A chip mounter and ball planting technology, which is applied in the field of BGA ball planting using SMT chip mounters, can solve the problems of unrecoverable solder ball height, unusable, large height gap, etc., to save production time, save costs, and improve production fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

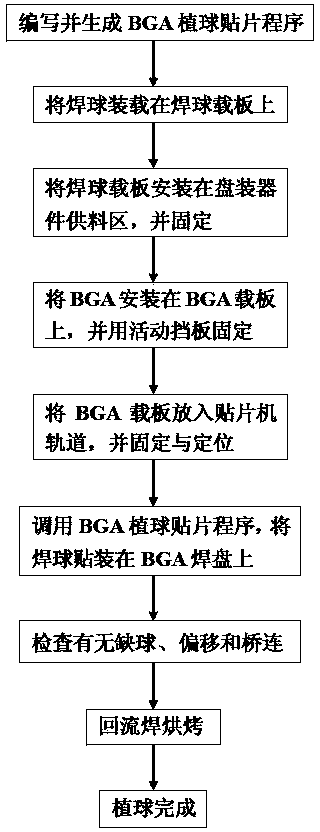

[0046] Such as figure 1 Shown, a kind of method utilizing SMT pick and place machine to carry out BGA ball planting, comprises the following steps:

[0047] Step A: Write and generate the BGA ball placement program. The BGA ball placement procedure includes the following steps:

[0048] 1) Data reading: read the information of the BGA to be balled, including BGA name, solder ball pitch (p), solder ball column number Xn, solder ball row number Ym; the method of data reading can be input manually or with automatic scanning.

[0049] 2) Data processing:

[0050] a. According to the number of solder ball rows Ym and the number of solder ball columns Xn, the number of solder balls 8 to be planted can be calculated as Xn*Ym;

[0051] b. According to the number of solder ball rows Ym, the number of solder ball columns Xn a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com