Fermented milk base material, whey-removed flavored fermented milk, raw material composite as well as preparation methods thereof

A technology of de-whey flavor and raw material composition, which is applied in the field of fermented milk base materials, can solve the problems of loss of heat-sensitive nutrients, poor taste of fermented milk, and inability to satisfy lactose, etc., and achieve stable texture and good water retention , low lactose content, enhance the effect of fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, a kind of whey-free flavor fermented milk and its preparation method

[0063] 1. Raw material formula:

[0064] Fermented milk base 93.0%, sucrose syrup 7.0%

[0065] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0066] Two, produce the product of the present embodiment according to following process method:

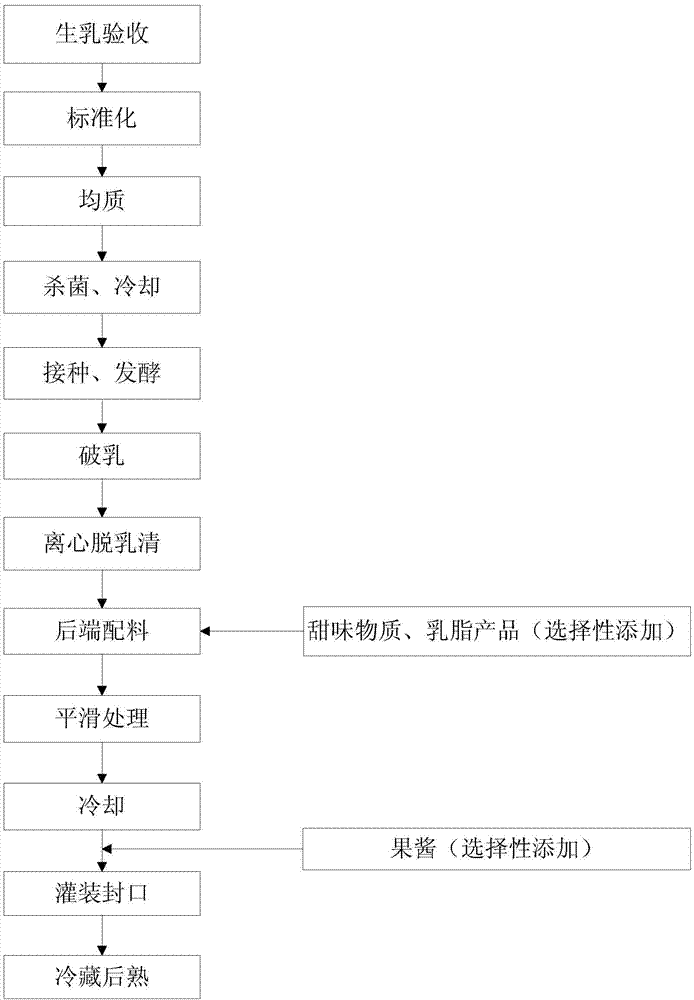

[0067] 1. Process flow:

[0068] Raw milk acceptance→standardization→homogenization→sterilization→cooling→inoculation, fermentation→demulsification→centrifugal dewhey→back-end ingredients (adding sucrose syrup)→smoothing treatment→cooling→filling and sealing→refrigerated and cooked

[0069] 2. Process description:

[0070] 2.1 Acceptance of raw milk: fat ≥ 3.1%, protein ≥ 2.85%, 72% alcohol test negative, acidity 12°T ~ 18°T, impurity ≤ 4mg / kg, milk temperature ≤ 4°C, normal boiling; sensory, pollutants And antibiotic residues and other indicators meet the standards of GB...

Embodiment 2

[0083] Embodiment 2, a kind of whey-free flavor fermented milk and its preparation method

[0084] 1. Raw material formula:

[0085] Fermented milk base 88.7%, cream 4.3%, sucrose syrup 7.0%

[0086] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0087] Two, produce the product of the present embodiment according to following process method:

[0088] 1. Process flow:

[0089] Raw milk inspection→standardization→homogenization→sterilization→cooling→inoculation, fermentation→demulsification→centrifugal whey removal→back-end ingredients (adding sucrose syrup and cream)→smoothing treatment→cooling→filling and sealing→refrigerated and cooked

[0090] 2. Process description:

[0091] 2.1 Acceptance of raw milk: fat ≥ 3.1%, protein ≥ 2.85%, 72% alcohol test negative, acidity 12°T ~ 18°T, impurity ≤ 4mg / kg, milk temperature ≤ 4°C, normal boiling; sensory, pollutants And antibiotic residues and other indicat...

Embodiment 3

[0104] Embodiment 3, a kind of whey-free flavor fermented milk and its preparation method

[0105] 1. Raw material formula:

[0106] Fermented milk base 80.7%, cream 3.3%, fructose syrup 4.0%, pineapple jam 12.0%

[0107] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0108] Two, produce the product of the present embodiment according to following process method:

[0109] 1. Process flow:

[0110] Raw milk acceptance→standardization→homogenization→sterilization→cooling→inoculation, fermentation→demulsification→centrifugation to remove whey→back-end ingredients (adding cream, fructose syrup)→smoothing treatment→cooling→adding pineapple jam→filling and sealing→ Refrigerated

[0111] 2. Process description:

[0112] 2.1 Acceptance of raw milk: fat ≥ 3.1%, protein ≥ 2.85%, 72% alcohol test negative, acidity 12°T ~ 18°T, impurity ≤ 4mg / kg, milk temperature ≤ 4°C, normal boiling; sensory, pollutants And ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com