Oval manhole ring machining tool

A manhole circle and oval-shaped technology, which is applied in the field of elliptical "manhole circle" processing tooling, can solve the problems of irregular ellipse shape, low efficiency, and increased manufacturing costs, so as to achieve good product quality, high production efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

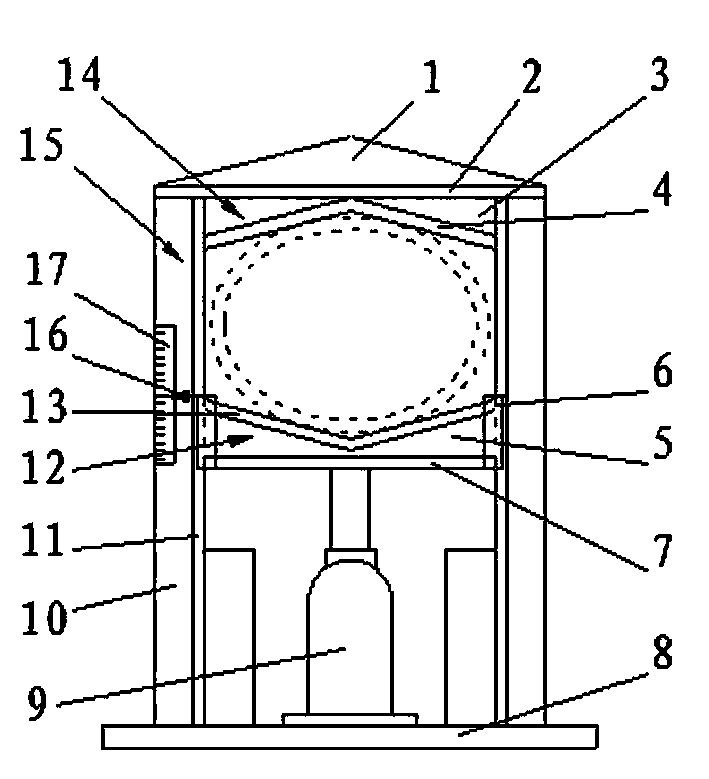

[0010] Such as figure 1 As shown, two elongated steel plates are connected in a T shape and welded together to form a T-shaped column 15. Two T-shaped columns 15 are welded and fixed on the two ends of the base plate 8, the upper pressing head 14 is welded and fixed on the top of the T-shaped column 15, and the lower pressing head 12 is clamped in the middle part of the T-shaped column 15 through the draw-in groove 6 and can be mounted along the T-shaped column. 15 moves up and down, the bottom of the oil top 9 is fixed on the middle part of the base plate 8, and the upper end connects the lower pressing head flat plate 7 on the lower pressing head 12.

[0011] Such as figure 1 As shown, the two ends of the top beam plate 2 in the upper pressure head 14 are welded and fixed on the T-shaped columns 15 on both sides and are perpendicular to the T-shaped columns 15; On the vertical plate 11, the upper end is welded and fixed on the roof beam plate 2, and the lower end is welded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com