Transmission device for welding line cutting

A transmission device and welding seam cutting technology, which is applied in the direction of driving device, feeding device, measuring/indicating equipment, etc., can solve the problems of fixed association and single processing condition, achieve high work efficiency, improve applicability, and improve operation safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

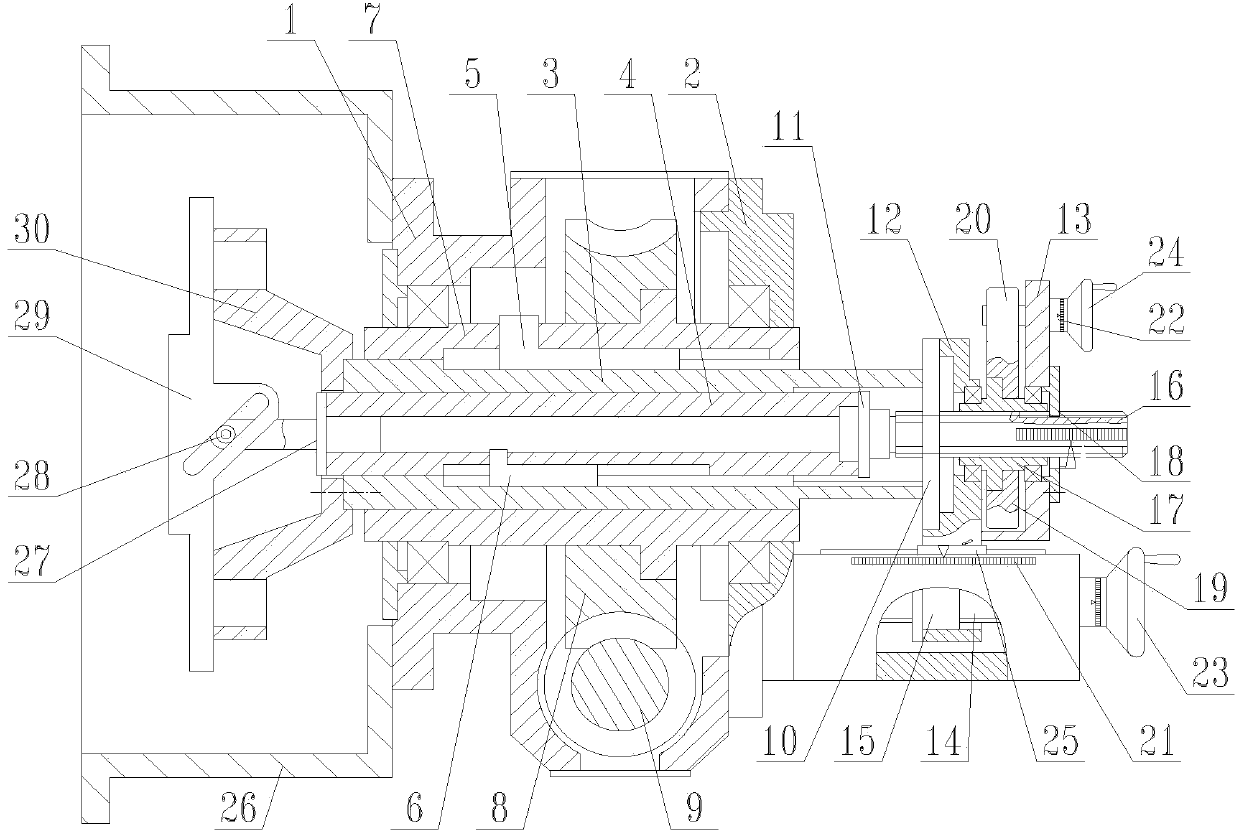

[0033] Such as figure 1 , 2As shown, the transmission device of the present invention is mainly composed of a machine base, and the machine base of the present invention is a combination of the frame 2 and the casing 1 . A transition flange 26 is also provided on the casing 1, through which the transmission device of the present invention can be installed on the host equipment.

[0034] A driving device is also arranged on the base, and the driving device includes a turbine shaft 7, which is connected to the frame 2 and the casing 1 through bearings respectively. A turbine 8 is also connected to the turbine shaft 7 , and a worm 9 is also connected to the turbine 8 . During use, motor is connected on the worm screw 9, and motor of the present invention is installed on the casing 1. Start the motor, then the power of the motor can be transmitted to the turbine 8 through the worm 9, and the turbine shaft 7 is driven to rotate by the turbine 8.

[0035] In order to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com