Full-automatic production line for packaging bags of civil explosive

A civilian explosive, fully automatic technology, applied in packaging and other directions, can solve the problems of high production cost, large area and high price of explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

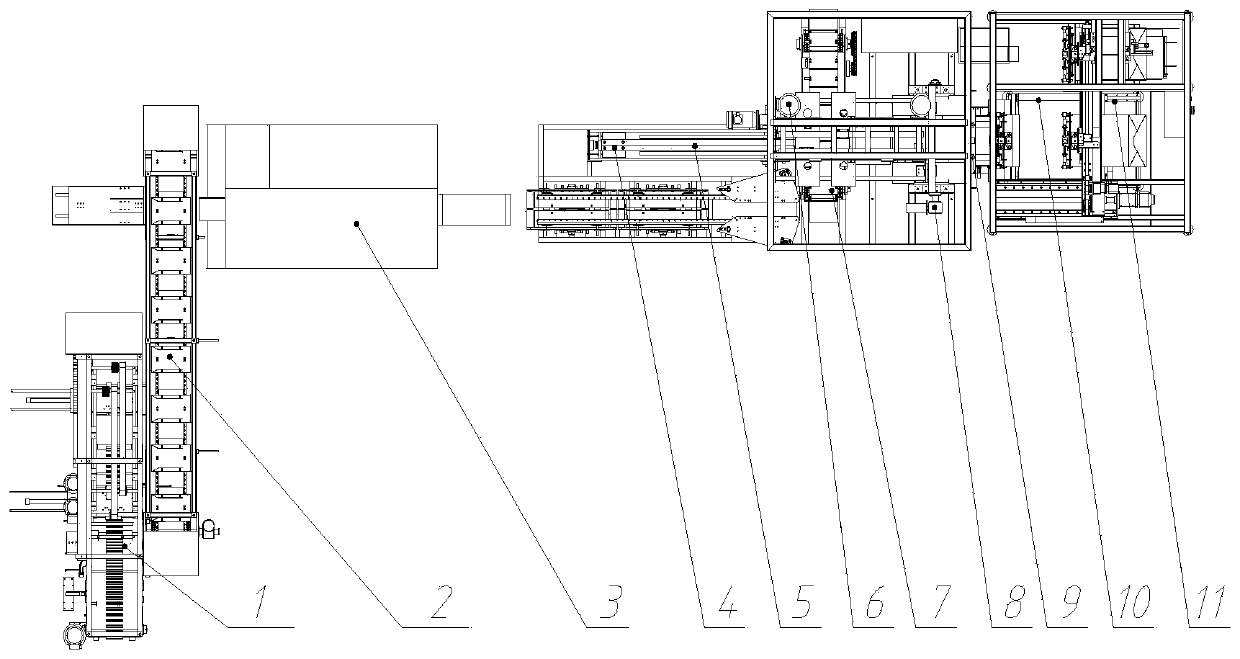

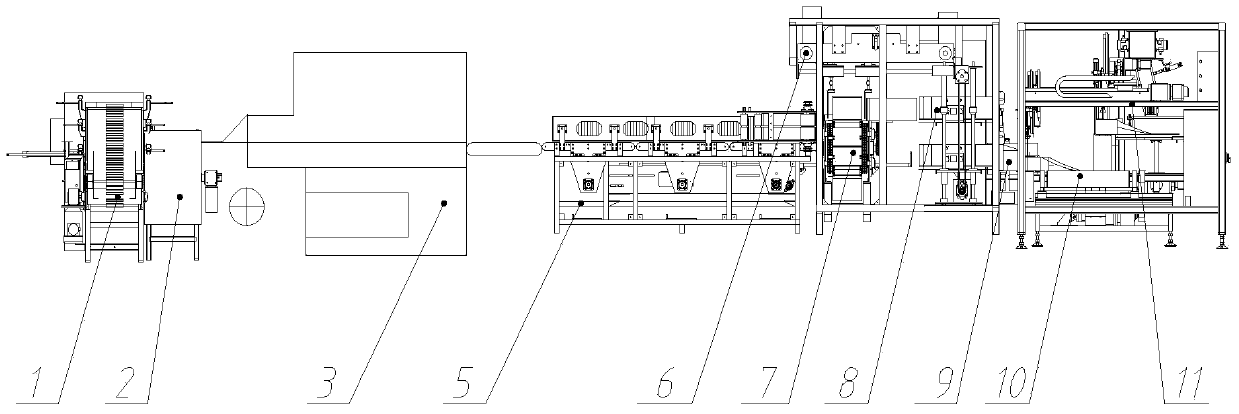

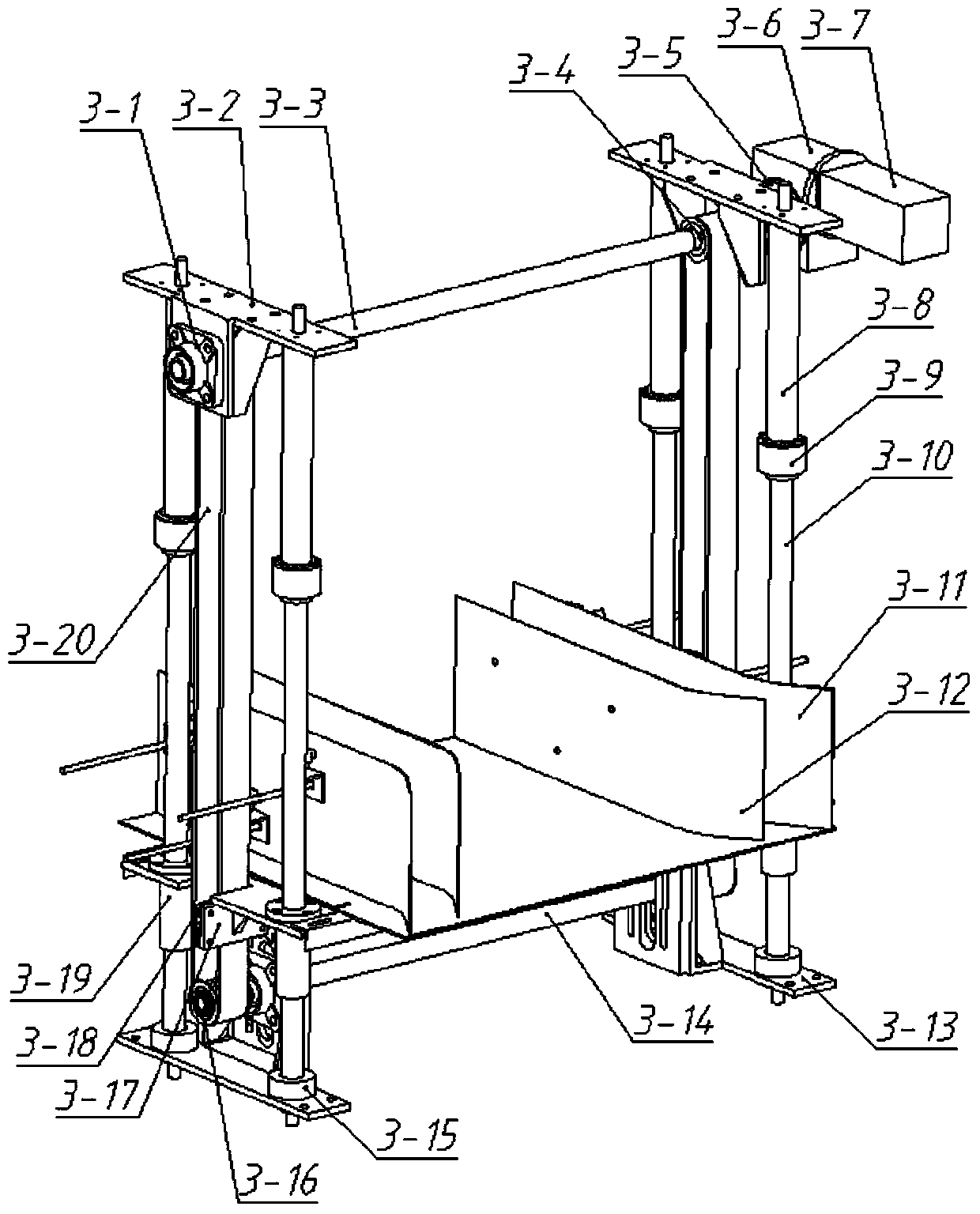

[0034] The present invention as figure 1 , figure 2 As shown in the figure, the production line for the packaging and bagging of civilian explosives includes an automatic card coder 1, a track conveyor 2, a tucking machine 3, a horizontal long push bag device 4, an all-in-one subpackage and bag delivery machine 5, and a circular push device 6. Card seat conveyor 7, stacking device 8, bag clamping device 9, translational belt device 10, fully automatic bagging machine 11; the feeding end of the automatic code card machine 1 is docked with the front-end feeding belt machine, and the automatic card code machine The discharge end of 1 is docked with the feed end of the track conveyor 2, the discharge end of the track conveyor 2 is docked with the feed end of the tundish machine 3, and the discharge end of the tundish machine 3 is connected with the all-in-one subpackaging machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com