A powder material transport vehicle

A technology for transporting vehicles and materials, which is applied in the field of powder material transporting vehicles. It can solve the problems of dual-power production cost and production difficulty, the remaining materials in the tank cannot be discharged, and occupy the effective volume, so as to enhance the practicality and driving stability. , enhance the structure and service life of the tank, and reduce the center of gravity of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

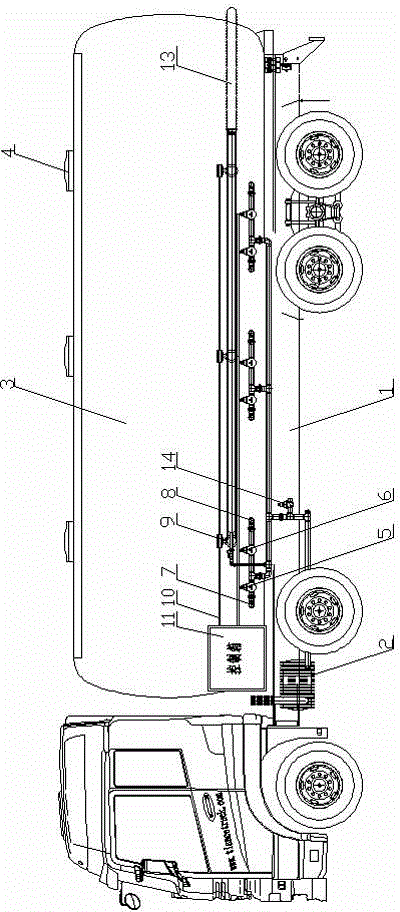

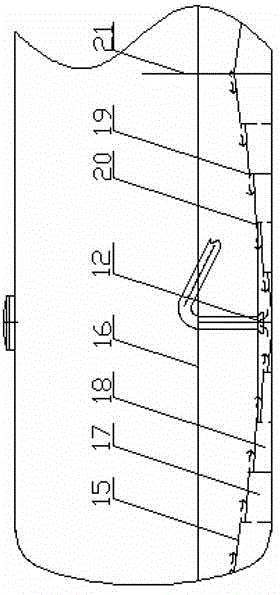

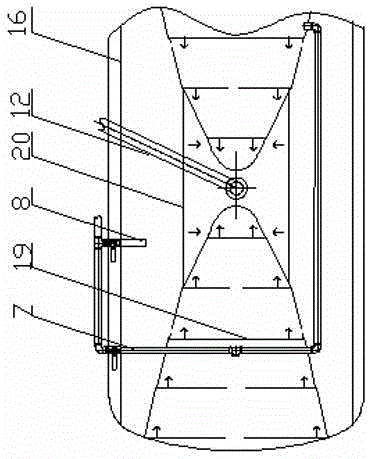

[0034] like figure 1 , figure 2 , image 3 and Figure 4 A kind of powder material transportation vehicle shown, comprises automobile chassis 1 and the tank body 3 that is installed on the automobile chassis, air compressor 2, unloading control system, and the tank body is divided into a plurality of compartments, each compartment There is a discharge port 12 in the center, and the fluidization system of the sub-bins adopts a layer-by-layer centripetal centralized fluidization form, that is, a layer-by-layer centripetal centralized fluidized bed;

[0035]The layer-by-layer centripetal centralized fluidized bed is centered on the discharge port 12, and multi-layer main flow guide plates 15 are symmetrically arranged on both sides along the length direction, and the main flow guide plates 15 are horizontal or have an inclination angle of 3-3 to the center. 5°, under the main deflector 15, it is divided into a high-level air chamber 17 and a bottom air chamber 18, and side de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com