Installing structure for washing machine draining pump

An installation structure and technology for washing machines, applied in the field of washing machines, can solve the problems of poor vibration damping effect, inconvenient maintenance, complicated installation, etc., and achieve the effects of simple and compact structure, reduction of vibration and noise, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

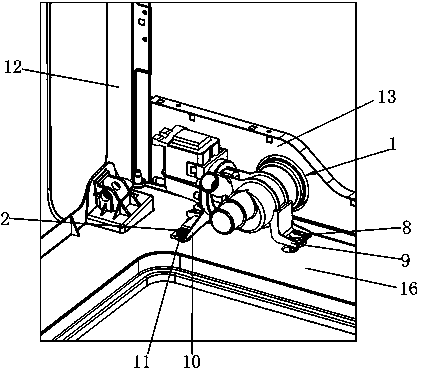

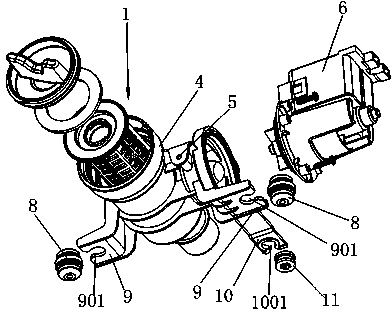

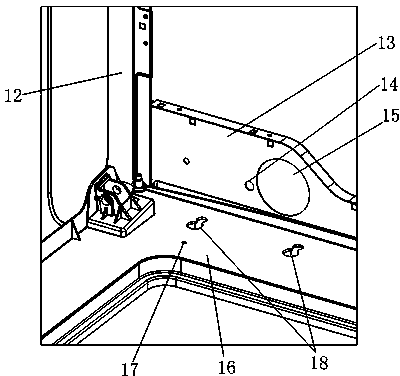

[0026] Such as Figure 1~6 As shown, the present invention includes a washing machine cabinet 12, the bottom of the cabinet 12 is provided with a front lower reinforcement 13 and a washing machine bottom cover 16, the front lower reinforcement 13 is arranged on the cabinet 12 at the front of the washing machine bottom cover 16, and the drain pump 1 passes through The main shock pad 8 is connected to the back cover 16 of the washing machine. The drainage pump 1 includes a pump body 4 and a motor assembly 6. Both sides of the lower part of the pump body 4 of the drainage pump 1 are provided with supporting feet 9, and the supporting feet 9 are provided with openings 901 facing the outside of the pump body. The openings 901 on the supporting feet 9 Located directly below the axis of the motor assembly 6 , the opening 901 on the supporting foot 9 is in the shape of "Ω", which can ensure stable positioning after being snapped into the main shock absorber 8 . The washing machine ba...

Embodiment 2

[0030] Such as figure 1 , 2 , 3, 5, 6, and 7, the present invention includes a washing machine cabinet 12, the bottom of the cabinet 12 is provided with a front lower reinforcement 13 and a washing machine bottom cover 16, and the front lower reinforcement 13 is arranged on the front of the washing machine bottom cover 16. On the body 12, the drain pump 1 is connected to the back cover 16 of the washing machine through the main shock pad 8. The drainage pump 1 includes a pump body 4 and a motor assembly 6. Both sides of the lower part of the pump body 4 of the drainage pump 1 are provided with supporting feet 9, and the supporting feet 9 are provided with openings 901 facing the outside of the pump body. The openings 901 on the supporting feet 9 Located directly below the axis of the motor assembly 6 , the opening 901 on the supporting foot 9 is in the shape of "Ω", which can ensure stable positioning after being snapped into the main shock absorber 8 . The washing machine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com