Magnus effect rotor utilizing wind energy to generate electricity and produce pushing force

A technology of thrust and effect, applied in the field of Magnus effect rotors, can solve problems such as low power generation efficiency, limited Magnus force, limited utilization of wind energy, etc., and achieve high economical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Describe the present invention below in conjunction with specific embodiment:

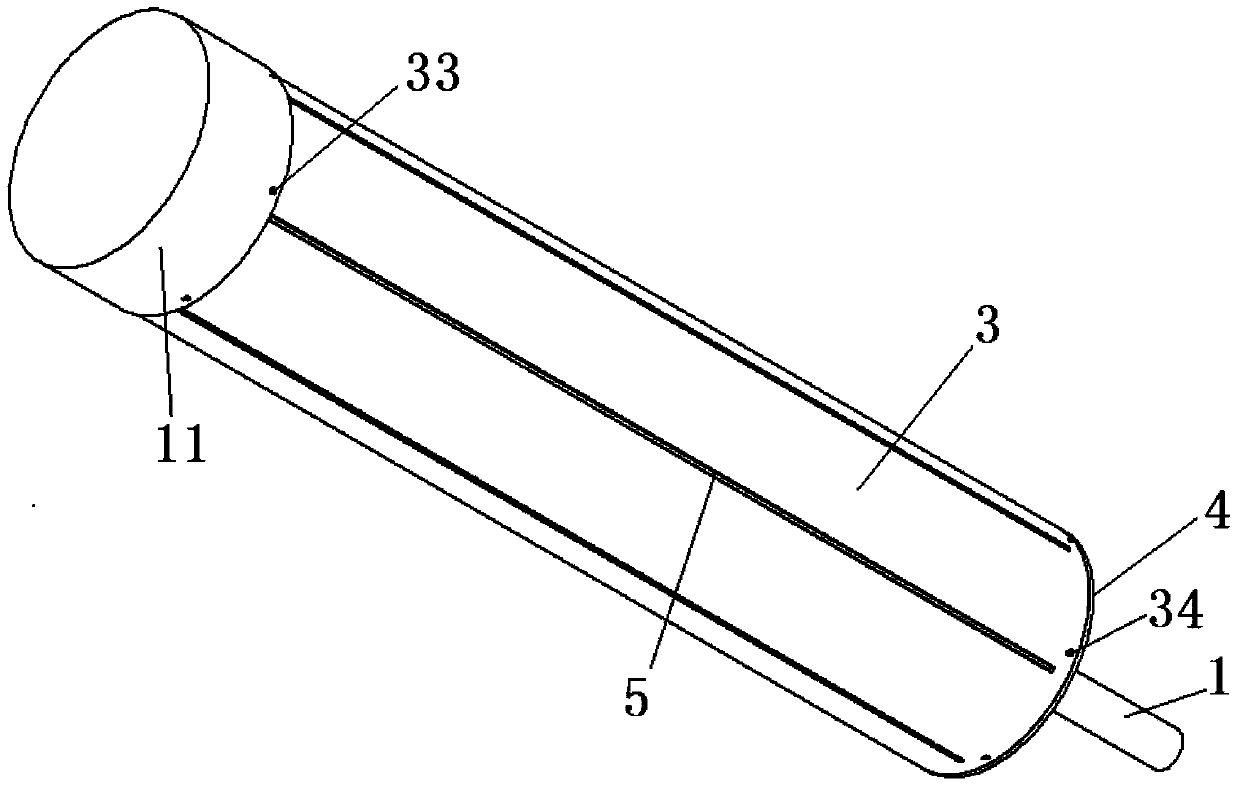

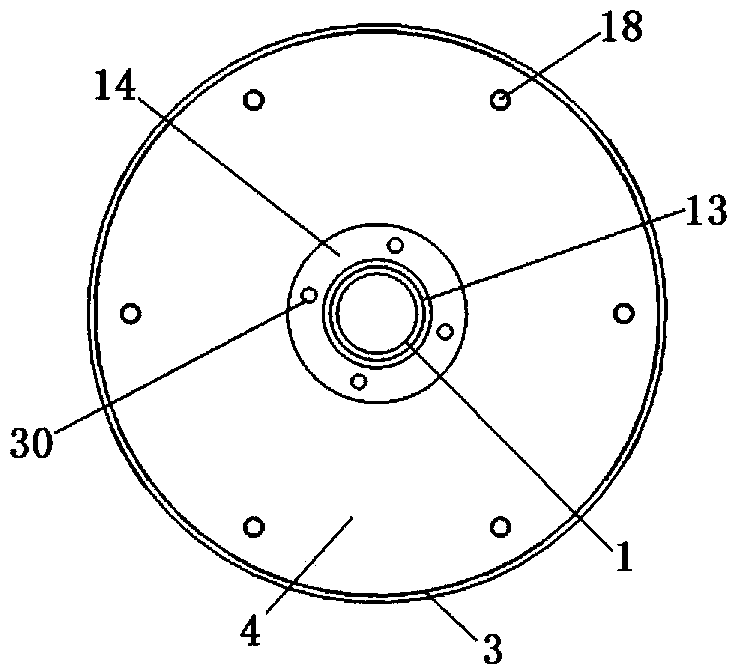

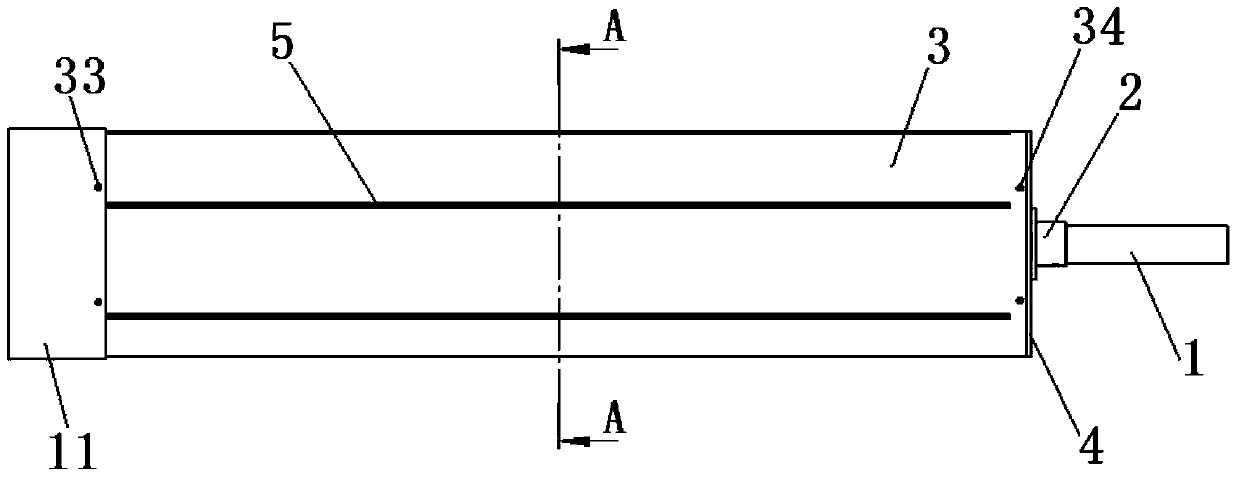

[0055] In this embodiment, the Magnus effect rotor utilizing wind energy for power generation and thrust generation includes a main shaft 1, a main rotor assembly, six sets of fan blade assemblies and a fan blade drive assembly.

[0056] The main drum assembly includes a main drum 3 , a main drum inner cover 4 and a main drum outer cover 7 . Refer to attached Figure 9 , the inner cover plate 4 of the main drum is connected and fixed to the main shaft 1 through the inner cover connector 2 of the main drum, and the outer cover plate 7 of the main drum is connected and fixed to the main shaft 1 through the outer cover connector 6 of the main drum. Refer to attached Figure 10 , the main shaft 1 is made of carbon fiber composite material, the shaft length is 1220mm, the outer diameter is 40mm, and the wall thickness is 3mm. There is a threaded through hole with a diameter of 6mm at a distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com