Wind power blade made of carbon-fiber and glass-fiber mixed materials

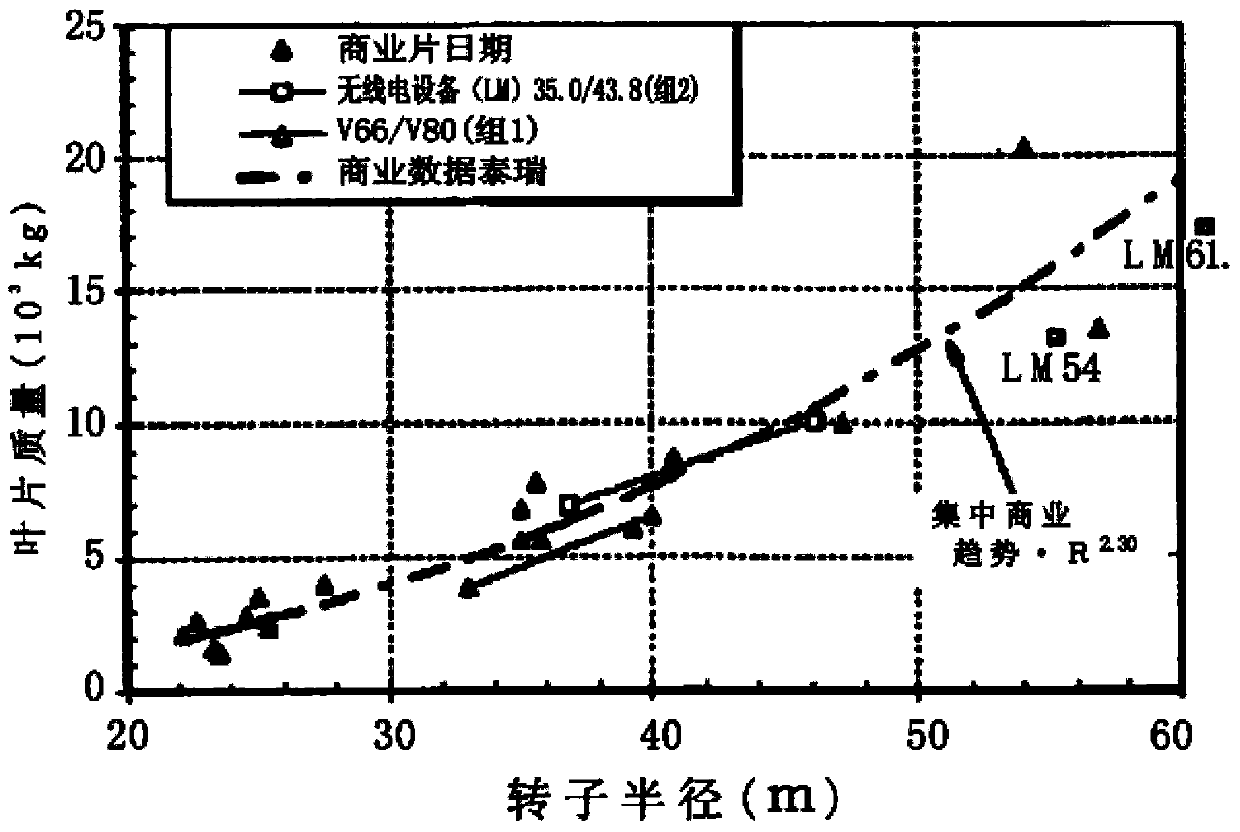

A technology for wind power blades and glass fiber fabrics, which is applied in wind power generation, wind turbine components, wind turbines, etc., can solve the problems of expensive carbon fiber and uneconomical cost, and achieve the effect of improving fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

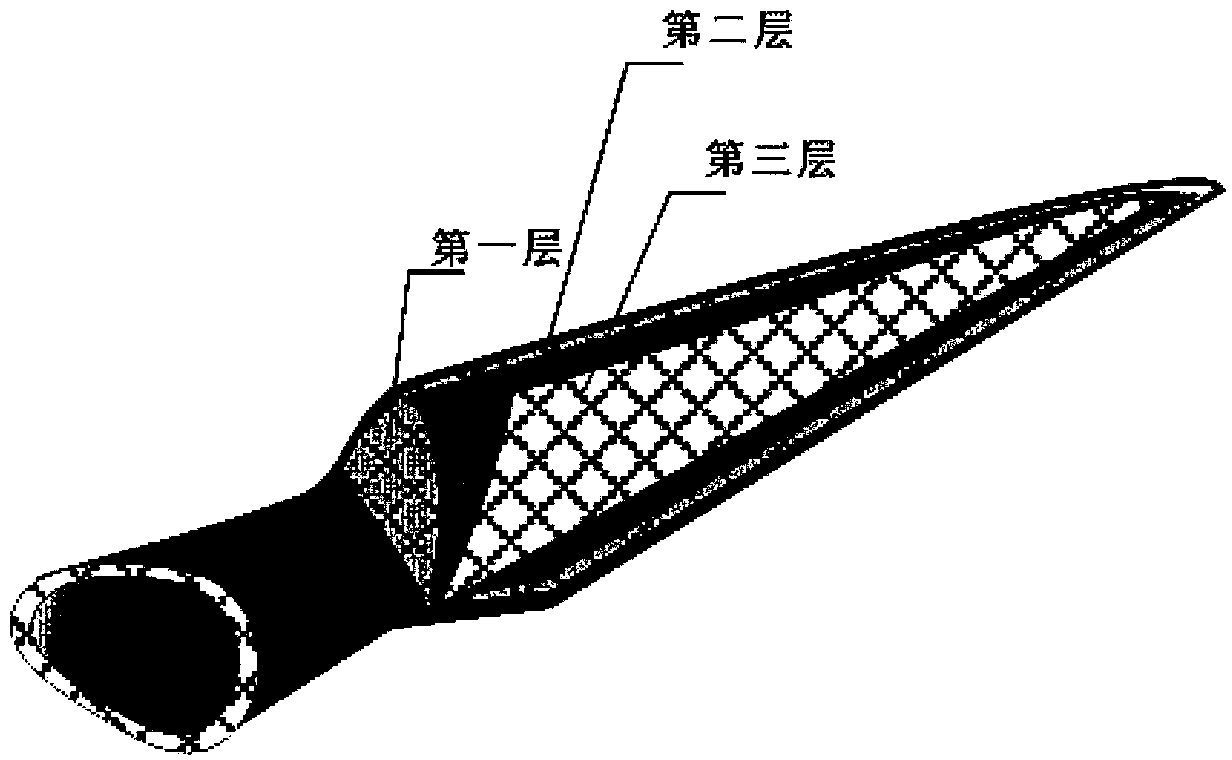

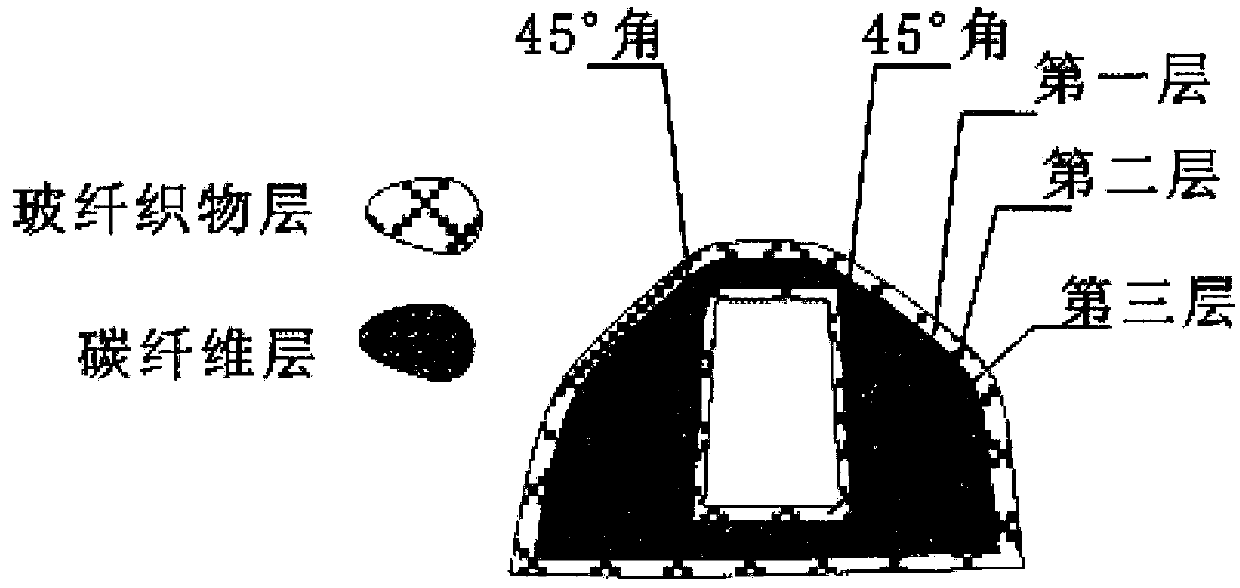

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] As shown in Figure 2, the structure of the wind power blade of the present invention is that the wind power blade is composed of three layers of materials, the first layer is a glass fiber fabric layer, the second layer is a carbon fiber layer, and the third layer is a glass fiber fabric layer. One layer of glass fiber fabric forms an angle of 45° with the third layer of glass fiber fabric, and the second layer of carbon fiber is sandwiched between the first layer of glass fiber fabric and the third layer of glass fiber fabric.

[0034] The first layer of glass fiber fabric layer 150g, the second layer of carbon fiber layer 500g, the third layer of glass fiber fabric layer 150g.

[0035]The composite material structure of wind power blades is an iterative process of selecting different materials and synthesizing various designs, in which the lami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com